A ceramic is any of the various hard, brittle, heat-resistant, and corrosion-resistant materials made by shaping and then firing an inorganic, nonmetallic material, such as clay, at a high temperature. Common examples are earthenware, porcelain, and brick.

A shaped charge is an explosive charge shaped to focus the effect of the explosive's energy. Different types of shaped charges are used for various purposes such as cutting and forming metal, initiating nuclear weapons, penetrating armor, or perforating wells in the oil and gas industry.

A kinetic energy penetrator (KEP), also known as long-rod penetrator (LRP), is a type of ammunition designed to penetrate vehicle armour using a flechette-like, high-sectional density projectile. Like a bullet or kinetic energy weapon, this type of ammunition does not contain explosive payloads and uses purely kinetic energy to penetrate the target. Modern KEP munitions are typically of the armour-piercing fin-stabilized discarding sabot (APFSDS) type.

Armour-piercing ammunition (AP) is a type of projectile designed to penetrate armour protection, most often including naval armour, body armour, and vehicle armour.

Composite armour is a type of vehicle armour consisting of layers of different materials such as metals, plastics, ceramics or air. Most composite armours are lighter than their all-metal equivalent, but instead occupy a larger volume for the same resistance to penetration. It is possible to design composite armour stronger, lighter and less voluminous than traditional armour, but the cost is often prohibitively high, restricting its use to especially vulnerable parts of a vehicle. Its primary purpose is to help defeat high-explosive anti-tank (HEAT) projectiles.

In materials science, a metal matrix composite (MMC) is a composite material with fibers or particles dispersed in a metallic matrix, such as copper, aluminum, or steel. The secondary phase is typically a ceramic or another metal. They are typically classified according to the type of reinforcement: short discontinuous fibers (whiskers), continuous fibers, or particulates. There is some overlap between MMCs and cermets, with the latter typically consisting of less than 20% metal by volume. When at least three materials are present, it is called a hybrid composite. MMCs can have much higher strength-to-weight ratios, stiffness, and ductility than traditional materials, so they are often used in demanding applications. MMCs typically have lower thermal and electrical conductivity and poor resistance to radiation, limiting their use in the very harshest environments.

A bulletproof vest, also known as a ballistic vest or a bullet-resistant vest, is an item of body armour that helps absorb the impact and reduce or stop penetration to the torso by firearm-fired projectiles and fragmentation from explosions. The vest may come in a soft form, as worn by many police officers, prison officers, security guards, and some private citizens, used to protect against stabbing attacks or light projectiles, or hard form, using metallic or para-aramid components. Soldiers and police tactical units wear hard armour, either in conjunction with soft armour or alone, to protect against rifle ammunition or fragmentation.

Chobham armour is the informal name of a composite armour developed in the 1960s at the Military Vehicles and Engineering Establishment, a British tank research centre on Chobham Lane in Chertsey. The name has since become the common generic term for composite ceramic vehicle armour. Other names informally given to Chobham armour include Burlington and Dorchester. Special armour is a broader informal term referring to any armour arrangement comprising sandwich reactive plates, including Chobham armour.

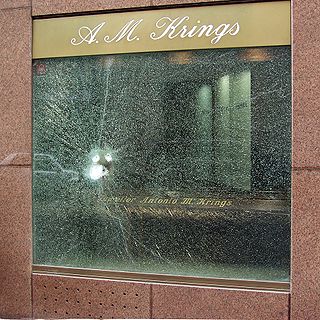

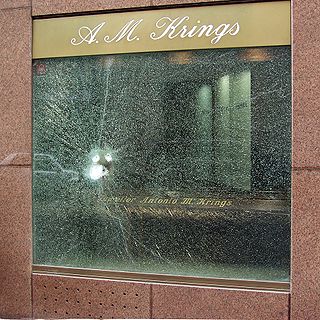

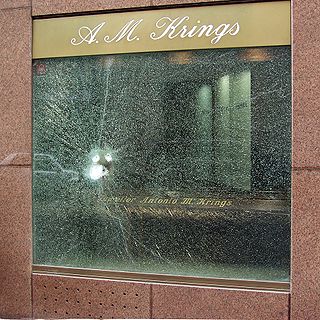

Bulletproof glass, ballistic glass, transparent armor, or bullet-resistant glass is a strong and optically transparent material that is particularly resistant to penetration by projectiles. Like any other material, it is not completely impenetrable. It is usually made from a combination of two or more types of glass, one hard and one soft. The softer layer makes the glass more elastic, so that it can flex instead of shatter. The index of refraction for all of the glasses used in the bulletproof layers must be almost the same to keep the glass transparent and allow a clear, undistorted view through the glass. Bulletproof glass varies in thickness from 3⁄4 to 3+1⁄2 inches.

A cermet is a composite material composed of ceramic and metal materials.

Military vehicles are commonly armoured to withstand the impact of shrapnel, bullets, shells, rockets, and missiles, protecting the personnel inside from enemy fire. Such vehicles include armoured fighting vehicles like tanks, aircraft, and ships.

Body armor, personal armor, armored suit (armoured) or coat of armor, among others, is armor for a person's body: protective clothing or close-fitting hands-free shields designed to absorb or deflect physical attacks. Historically used to protect military personnel, today it is also used by various types of police, private security guards, or bodyguards, and occasionally ordinary citizens. Today there are two main types: regular non-plated body armor for moderate to substantial protection, and hard-plate reinforced body armor for maximum protection, such as used by combatants.

Bulletproofing is the process of making an object capable of stopping a bullet or similar high velocity projectiles. The term bullet resistance is often preferred because few, if any, practical materials provide complete protection against all types of bullets, or multiple hits in the same location, or simply sufficient kinetic (movement) energy to overcome it.

The Small Arms Protective Insert (SAPI) is a ceramic ballistic plate used by the United States Armed Forces. It was first used in the Ranger Body Armor and Interceptor Body Armor, both are ballistic vests. It is now also used in the Improved Outer Tactical Vest as well as the Modular Tactical Vest, in addition to commercially available "plate carriers". The Kevlar Interceptor vest itself is designed to stop projectiles up to and including 9×19mm Parabellum submachine gun rounds, in addition to fragmentation. To protect against higher-velocity rifle rounds, SAPI plates are needed.

A ballistic plate, also known as an armour plate, is a protective armoured plate inserted into a carrier or bulletproof vest, that can be used stand-alone, or in conjunction with other armour. "Hard armour" usually denotes armour that uses ballistic plates.

Armour with two or more plates spaced a distance apart falls under the category of spaced armour. Spaced armour can be sloped or unsloped. When sloped, it reduces the penetrating power of bullets and solid shot, as after penetrating each plate projectiles tend to tumble, deflect, deform, or disintegrate; spaced armour that is not sloped is generally designed to provide protection from explosive projectiles, which detonate before reaching the primary armour. Spaced armour is used on military vehicles such as tanks and combat bulldozers. In a less common application, it is used in some spacecraft that use Whipple shields.

Ceramic engineering is the science and technology of creating objects from inorganic, non-metallic materials. This is done either by the action of heat, or at lower temperatures using precipitation reactions from high-purity chemical solutions. The term includes the purification of raw materials, the study and production of the chemical compounds concerned, their formation into components and the study of their structure, composition and properties.

The Improved Outer Tactical Vest (IOTV) is an enhanced version of, and a replacement for, the older Outer Tactical Vest (OTV) component of the Interceptor multi-threat body armor system, as fielded by the United States Army beginning in the mid-2000s. The IOTV is compatible with the Deltoid and Axillary Protector System (DAPS) components, ESAPI, Enhanced Side Ballistic Inserts (ESBI), as well as the OTV's groin protector. A flame-resistant standalone shirt, the Army Combat Shirt (ACS), was designed in the late 2000s specifically for use with the IOTV.

Solid is one of the four fundamental states of matter along with liquid, gas, and plasma. The molecules in a solid are closely packed together and contain the least amount of kinetic energy. A solid is characterized by structural rigidity and resistance to a force applied to the surface. Unlike a liquid, a solid object does not flow to take on the shape of its container, nor does it expand to fill the entire available volume like a gas. The atoms in a solid are bound to each other, either in a regular geometric lattice, or irregularly. Solids cannot be compressed with little pressure whereas gases can be compressed with little pressure because the molecules in a gas are loosely packed.