An engine or motor is a machine designed to convert one or more forms of energy into mechanical energy.

A steam engine is a heat engine that performs mechanical work using steam as its working fluid. The steam engine uses the force produced by steam pressure to push a piston back and forth inside a cylinder. This pushing force can be transformed, by a connecting rod and crank, into rotational force for work. The term "steam engine" is generally applied only to reciprocating engines as just described, not to the steam turbine. Steam engines are external combustion engines, where the working fluid is separated from the combustion products. The ideal thermodynamic cycle used to analyze this process is called the Rankine cycle. In general usage, the term steam engine can refer to either complete steam plants, such as railway steam locomotives and portable engines, or may refer to the piston or turbine machinery alone, as in the beam engine and stationary steam engine.

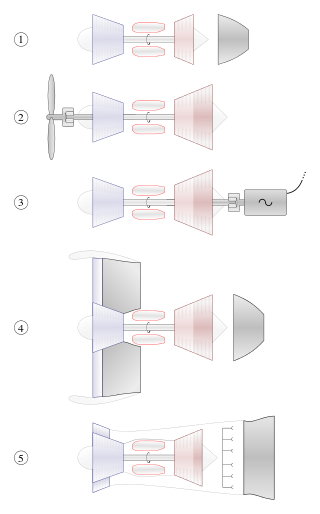

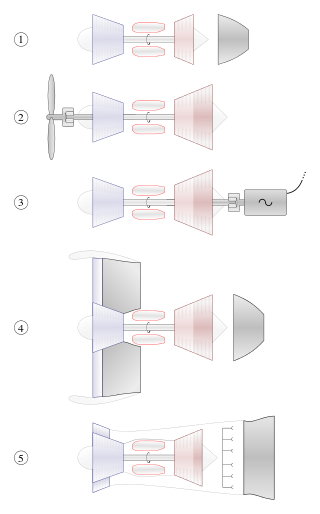

A gas turbine, also called a combustion turbine, is a type of continuous flow internal combustion engine. The main parts common to all gas turbine engines form the power-producing part and are, in the direction of flow:

A power station, also referred to as a power plant and sometimes generating station or generating plant, is an industrial facility for the generation of electric power. Power stations are generally connected to an electrical grid.

A diesel locomotive is a type of railway locomotive in which the power source is a diesel engine. Several types of diesel locomotives have been developed, differing mainly in the means by which mechanical power is conveyed to the driving wheels. The most common are diesel-electric locomotives and diesel-hydraulic.

A combined cycle power plant is an assembly of heat engines that work in tandem from the same source of heat, converting it into mechanical energy. On land, when used to make electricity the most common type is called a combined cycle gas turbine (CCGT) plant. The same principle is also used for marine propulsion, where it is called a combined gas and steam (COGAS) plant. Combining two or more thermodynamic cycles improves overall efficiency, which reduces fuel costs.

Cogeneration or combined heat and power (CHP) is the use of a heat engine or power station to generate electricity and useful heat at the same time.

A fossil fuel power station is a thermal power station which burns a fossil fuel, such as coal or natural gas, to produce electricity. Fossil fuel power stations have machinery to convert the heat energy of combustion into mechanical energy, which then operates an electrical generator. The prime mover may be a steam turbine, a gas turbine or, in small plants, a reciprocating gas engine. All plants use the energy extracted from the expansion of a hot gas, either steam or combustion gases. Although different energy conversion methods exist, all thermal power station conversion methods have their efficiency limited by the Carnot efficiency and therefore produce waste heat.

Peaking power plants, also known as peaker plants, and occasionally just "peakers", are power plants that generally run only when there is a high demand, known as peak demand, for electricity. Because they supply power only occasionally, the power supplied commands a much higher price per kilowatt hour than base load power. Peak load power plants are dispatched in combination with base load power plants, which supply a dependable and consistent amount of electricity, to meet the minimum demand.

A gas turbine locomotive is a type of railway locomotive in which the prime mover is a gas turbine. Several types of gas turbine locomotive have been developed, differing mainly in the means by which mechanical power is conveyed to the driving wheels (drivers). A gas turbine train typically consists of two power cars, and one or more intermediate passenger cars.

A steam turbine locomotive is a steam locomotive which transmits steam power to the wheels via a steam turbine. Numerous attempts at this type of locomotive were made, mostly without success. In the 1930s this type of locomotive was seen as a way both to revitalize steam power and challenge the diesel locomotives then being introduced.

A thermal power station is a type of power station in which heat energy is converted to electrical energy. In a steam-generating cycle heat is used to boil water in a large pressure vessel to produce high-pressure steam, which drives a steam turbine connected to an electrical generator. The low-pressure exhaust from the turbine enters a steam condenser where it is cooled to produce hot condensate which is recycled to the heating process to generate more high pressure steam. This is known as a Rankine cycle.

Combined gas and steam (COGAS) is the name given to marine compound powerplants comprising gas and steam turbines, the latter being driven by steam generated using the heat from the exhaust of the gas turbines. In this way, some of the otherwise lost energy can be reclaimed and the specific fuel consumption of the plant can be decreased. Large (land-based) electric powerplants built using this combined cycle can reach conversion efficiencies of over 60%.

The steam-electric power station is a power station in which the electric generator is steam driven. Water is heated, turns into steam and spins a steam turbine which drives an electrical generator. After it passes through the turbine, the steam is condensed in a condenser. The greatest variation in the design of steam-electric power plants is due to the different fuel sources.

Engine efficiency of thermal engines is the relationship between the total energy contained in the fuel, and the amount of energy used to perform useful work. There are two classifications of thermal engines-

- Internal combustion and

- External combustion engines.

Marine propulsion is the mechanism or system used to generate thrust to move a watercraft through water. While paddles and sails are still used on some smaller boats, most modern ships are propelled by mechanical systems consisting of an electric motor or internal combustion engine driving a propeller, or less frequently, in pump-jets, an impeller. Marine engineering is the discipline concerned with the engineering design process of marine propulsion systems.

The Union Pacific GTELs were a series of gas turbine-electric locomotives built by Alco-GE and General Electric between 1952-1961 and operated by Union Pacific from 1952 to 1970.

Advanced steam technology reflects an approach to the technical development of the steam engine intended for a wider variety of applications than has recently been the case. Particular attention has been given to endemic problems that led to the demise of steam power in small- to medium-scale commercial applications: excessive pollution, maintenance costs, labour-intensive operation, low power/weight ratio, and low overall thermal efficiency; where steam power has generally now been superseded by the internal combustion engine or by electrical power drawn from an electrical grid. The only steam installations that are in widespread use are the highly efficient thermal power plants used for generating electricity on a large scale. In contrast, the proposed steam engines may be for stationary, road, rail or marine use.

An internal combustion engine is a heat engine in which the combustion of a fuel occurs with an oxidizer in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal combustion engine, the expansion of the high-temperature and high-pressure gases produced by combustion applies direct force to some component of the engine. The force is typically applied to pistons, turbine blades, a rotor, or a nozzle. This force moves the component over a distance, transforming chemical energy into kinetic energy which is used to propel, move or power whatever the engine is attached to.

A turbine–electric transmission system includes a turboshaft gas turbine connected to an electrical generator, creating electricity that powers electric traction motors. No clutch is required.