Related Research Articles

A work-breakdown structure (WBS) in project management and systems engineering is a deliverable-oriented breakdown of a project into smaller components. A work breakdown structure is a key project management element that organizes the team's work into manageable sections. The Project Management Body of Knowledge defines the work-breakdown structure as a "hierarchical decomposition of the total scope of work to be carried out by the project team to accomplish the project objectives and create the required deliverables."

Configuration management (CM) is a management process for establishing and maintaining consistency of a product's performance, functional, and physical attributes with its requirements, design, and operational information throughout its life. The CM process is widely used by military engineering organizations to manage changes throughout the system lifecycle of complex systems, such as weapon systems, military vehicles, and information systems. Outside the military, the CM process is also used with IT service management as defined by ITIL, and with other domain models in the civil engineering and other industrial engineering segments such as roads, bridges, canals, dams, and buildings.

A statement of work (SOW) is a document routinely employed in the field of project management. It is the narrative description of a project's work requirement. It defines project-specific activities, deliverables and timelines for a vendor providing services to the client. The SOW typically also includes detailed requirements and pricing, with standard regulatory and governance terms and conditions. It is often an important accompaniment to a master service agreement or request for proposal (RFP).

The Information Services Procurement Library (ISPL) is a best practice library for the management of Information Technology related acquisition processes. It helps both the customer and supplier organization to achieve the desired quality using the corresponded amount of time and money by providing methods and best practices for risk management, contract management, and planning. ISPL focuses on the relationship between the customer and supplier organization: It helps constructing the request for proposal, it helps constructing the contract and delivery plan according to the project situation and risks, and it helps monitoring the delivery phase. ISPL is a unique Information Technology method because where most other Information Technology methods and frameworks focus on development, ISPL focuses purely on the procurement of information services. The target audience for ISPL consists of procurement managers, acquisition managers, programme managers, contract managers, facilities managers, service level managers, and project managers in the IT area. Because of ISPL's focus on procurement it is very suitable to be used with ITIL and PRINCE2.

MIL-STD-498, Military Standard Software Development and Documentation, was a United States military standard whose purpose was to "establish uniform requirements for software development and documentation." It was released Nov. 8, 1994, and replaced DOD-STD-2167A, DOD-STD-2168, DOD-STD-7935A, and DOD-STD-1703. It was meant as an interim standard, to be in effect for about two years until a commercial standard was developed.

A United States defense standard, often called a military standard, "MIL-STD", "MIL-SPEC", or (informally) "MilSpecs", is used to help achieve standardization objectives by the U.S. Department of Defense.

Integrated logistics support (ILS) is a technology in the system engineering to lower a product life cycle cost and decrease demand for logistics by the maintenance system optimization to ease the product support. Although originally developed for military purposes, it is also widely used in commercial customer service organisations.

The Federal Acquisition Regulation (FAR) is the principal set of rules regarding Government procurement in the United States, and is codified at Chapter 1 of Title 48 of the Code of Federal Regulations, 48 CFR 1. It covers many of the contracts issued by the US military and NASA, as well as US civilian federal agencies.

Environmental stress screening (ESS) refers to the process of exposing a newly manufactured or repaired product or component to stresses such as thermal cycling and vibration in order to force latent defects to manifest themselves by permanent or catastrophic failure during the screening process. The surviving population, upon completion of screening, can be assumed to have a higher reliability than a similar unscreened population.

MIL-STD-810, U.S. Department of Defense Test Method Standard, Environmental Engineering Considerations and Laboratory Tests, is a United States Military Standard that emphasizes tailoring an equipment's environmental design and test limits to the conditions that it will experience throughout its service life, and establishing chamber test methods that replicate the effects of environments on the equipment rather than imitating the environments themselves. Although prepared specifically for U.S. military applications, the standard is often applied for commercial products as well.

In the United States, the processes of government procurement enable federal, state and local government bodies in the country to acquire goods, services, and interests in real property. Contracting with the federal government or with state and local public bodies enables interested businesses to become suppliers in these markets.

DOD-STD-2167A, titled "Defense Systems Software Development", was a United States defense standard, published on February 29, 1988, which updated the less well known DOD-STD-2167 published 4 June 1985. This document established "uniform requirements for the software development that are applicable throughout the system life cycle." This revision was written to allow the contractor more flexibility and was a significant reorganization and reduction of the previous revision; e.g.., where the previous revision prescribed pages of design and coding standards, this revision only gave one page of general requirements for the contractor's coding standards; while DOD-STD-2167 listed 11 quality factors to be addressed for each software component in the SRS, DOD-STD-2167A only tasked the contractor to address relevant quality factors in the SRS. Like DOD-STD-2167, it was designed to be used with DOD-STD-2168, "Defense System Software Quality Program".

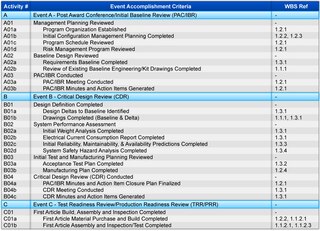

In the United States Department of Defense, the Integrated Master Plan (IMP) and the Integrated Master Schedule (IMS) are important program management tools that provide significant assistance in the planning and scheduling of work efforts in large and complex materiel acquisitions. The IMP is an event-driven plan that documents the significant accomplishments necessary to complete the work and ties each accomplishment to a key program event. The IMP is expanded to a time-based IMS to produce a networked and multi-layered schedule showing all detailed tasks required to accomplish the work effort contained in the IMP. The IMS flows directly from the IMP and supplements it with additional levels of detail——both then form the foundations to implement an Earned Value Management System.

A specification often refers to a set of documented requirements to be satisfied by a material, design, product, or service. A specification is often a type of technical standard.

MIL-STD-130, "Identification Marking of U.S. Military Property," is a specification that describes markings required on items sold to the Department of Defense (DoD), including the addition, in about 2005, of UII Data Matrix machine-readable information (MRI) requirements. MIL-STD-130 describes the materials allowed, minimum text size and fonts, format, syntax and rules for identifying marks on a part, where to locate this marking plus exceptions and unique situations, such as vehicle identification numbers, cell phone IDs, etc. Other non-identifying markings—such as "this end up"—are covered under MIL-STD-129.

Unique Identification Marking, UID marking, Item Unique Identification or IUID, is a part of the compliance process mandated by the United States Department of Defense. It is a permanent marking method used to give equipment a unique ID. Marking is essential for all equipment with an acquisition cost of over $5,000, equipment which is mission essential, controlled inventory, or serially-controlled. UID-marking is a set of data for assets that is globally unique and unambiguous. The technology used to mark an item is 2D Data Matrix ECC 200 Symbol. UID marking can be used to ensure data integrity and data quality throughout an item's lifecycle; it also supports multi-faceted business applications.

In a manufacturing environment, a request for waiver (RFW) is a request for authorization to accept an item which, during manufacture or after inspection, is found to depart from specified requirements, but nevertheless is considered suitable for use as is or after repair by an approved method.

The dynamic design analysis method (DDAM) is a US Navy-developed analytical procedure for evaluating the design of equipment subject to dynamic loading caused by underwater explosions (UNDEX). The analysis uses a form of shock spectrum analysis that estimates the dynamic response of a component to shock loading caused by the sudden movement of a naval vessel. The analytical process simulates the interaction between the shock-loaded component and its fixed structure, and it is a standard naval engineering procedure for shipboard structural dynamics.

A United States data item description (DID) is a completed document defining the data deliverables required of a United States Department of Defense contractor. A DID specifically defines the data content, format, and intended use of the data with a primary objective of achieving standardization objectives by the U.S. Department of Defense. The content and format requirements for DIDs are defined within MIL-STD-963C, Data Item Descriptions (2014).

The statement of objectives is one part of a request for proposal from the U.S. Government. The statement of objectives is an alternative to a government prepared statement of work (SOW). A SOO provides the government's overall objectives and the offeror's required support to achieve the contractual objectives. Offerors use the SOO as a basis for preparing a SOW which is then included as an integral part of the proposal which the government evaluates during the source selection.