Crepe rubber is coagulated latex that is rolled out in crinkled sheets and commonly used to make soles for shoes and boots but also a raw material for further processed rubber products.

Crepe rubber is coagulated latex that is rolled out in crinkled sheets and commonly used to make soles for shoes and boots but also a raw material for further processed rubber products.

After the collection of the latex milk, sodium sulphite (Na2SO3) or ammonia is added to prevent coagulation. [1]

When the latex arrives in the factory, sodium bisulphite (NaHSO3) or sodium metabisulphite (Na2S2O3) are added to prevent enzymatic reactions and discoloring. [1]

Sodium para toluene thiophenate (an aromatic mercaptan) is often added as a bleaching agent. [1]

Colloidal latex is then mixed with formic acid to cause it to coagulate. The coagulum is processed in a "creping battery", a series of machines that crush, press, and roll the coagula. The sheets are then hung in a heated drying shed and, after drying, sorted by grade and packed for shipping. [1]

There are several types and grades of rubber crepe, mainly distinguished by the grade and pre-processing of the latex used in their manufacture. [2]

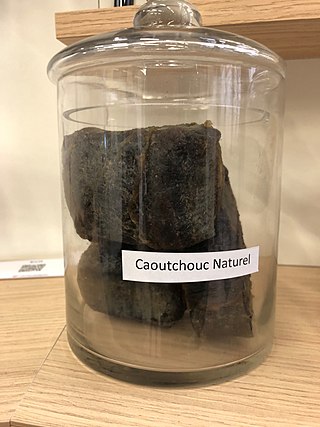

Rubber, also called India rubber, latex, Amazonian rubber, caucho, or caoutchouc, as initially produced, consists of polymers of the organic compound isoprene, with minor impurities of other organic compounds. Thailand, Malaysia, Indonesia, and Cambodia are four of the leading rubber producers.

Flooring is the general term for a permanent covering of a floor, or for the work of installing such a floor covering. Floor covering is a term to generically describe any finish material applied over a floor structure to provide a walking surface. Both terms are used interchangeably but floor covering refers more to loose-laid materials.

In polymer chemistry, emulsion polymerization is a type of radical polymerization that usually starts with an emulsion incorporating water, monomers, and surfactants. The most common type of emulsion polymerization is an oil-in-water emulsion, in which droplets of monomer are emulsified in a continuous phase of water. Water-soluble polymers, such as certain polyvinyl alcohols or hydroxyethyl celluloses, can also be used to act as emulsifiers/stabilizers. The name "emulsion polymerization" is a misnomer that arises from a historical misconception. Rather than occurring in emulsion droplets, polymerization takes place in the latex/colloid particles that form spontaneously in the first few minutes of the process. These latex particles are typically 100 nm in size, and are made of many individual polymer chains. The particles are prevented from coagulating with each other because each particle is surrounded by the surfactant ('soap'); the charge on the surfactant repels other particles electrostatically. When water-soluble polymers are used as stabilizers instead of soap, the repulsion between particles arises because these water-soluble polymers form a 'hairy layer' around a particle that repels other particles, because pushing particles together would involve compressing these chains.

A paper machine is an industrial machine which is used in the pulp and paper industry to create paper in large quantities at high speed. Modern paper-making machines are based on the principles of the Fourdrinier Machine, which uses a moving woven mesh to create a continuous paper web by filtering out the fibres held in a paper stock and producing a continuously moving wet mat of fibre. This is dried in the machine to produce a strong paper web.

A frisket is any material that protects areas of a work from unintended change.

A mop is a mass or bundle of coarse strings or yarn, etc., or a piece of cloth, sponge or other absorbent material, attached to a pole or stick. It is used to soak up liquid, for cleaning floors and other surfaces, to mop up dust, or for other cleaning purposes.

Particle board, also known as particleboard, chipboard, and low-density fiberboard, is an engineered wood product manufactured from wood chips and a synthetic resin or other suitable binder, which is pressed and extruded. Particle board is often confused with oriented strand board, a different type of fiberboard that uses machined wood flakes and offers more strength.

Coffee production is the industrial process of converting the raw fruit of the coffee plant into the finished coffee. The coffee cherry has the fruit or pulp removed leaving the seed or bean which is then dried. While all green coffee is processed, the method that is used varies and can have a significant effect on the flavor of roasted and brewed coffee. Coffee production is a major source of income for 12.5 million households, most in developing countries.

Acrylic fibers are synthetic fibers made from a polymer (polyacrylonitrile) with an average molecular weight of ~100,000, about 1900 monomer units. For a fiber to be called "acrylic" in the US, the polymer must contain at least 85% acrylonitrile monomer. Typical comonomers are vinyl acetate or methyl acrylate. DuPont created the first acrylic fibers in 1941 and trademarked them under the name Orlon. It was first developed in the mid-1940s but was not produced in large quantities until the 1950s. Strong and warm, acrylic fiber is often used for sweaters and tracksuits and as linings for boots and gloves, as well as in furnishing fabrics and carpets. It is manufactured as a filament, then cut into short staple lengths similar to wool hairs, and spun into yarn.

Textile manufacturing is a major industry. It is largely based on the conversion of fibre into yarn, then yarn into fabric. These are then dyed or printed, fabricated into cloth which is then converted into useful goods such as clothing, household items, upholstery and various industrial products.

Nitrile rubber, also known as nitrile butadiene rubber, NBR, Buna-N, and acrylonitrile butadiene rubber, is a synthetic rubber derived from acrylonitrile (ACN) and butadiene. Trade names include Perbunan, Nipol, Krynac and Europrene. This rubber is unusual in being resistant to oil, fuel, and other chemicals.

Latex rubber is used in the manufacture of many types of clothing. It has traditionally been used to make protective clothing, including gas masks and Wellington boots. Mackintoshes have traditionally been made from rubberized cloth. However, rubber has now generally been replaced in these applications by synthetic polymers.

Nonwoven fabric or non-woven fabric is a fabric-like material made from staple fibre (short) and long fibres, bonded together by chemical, mechanical, heat or solvent treatment. The term is used in the textile manufacturing industry to denote fabrics, such as felt, which are neither woven nor knitted. Some non-woven materials lack sufficient strength unless densified or reinforced by a backing. In recent years, non-wovens have become an alternative to polyurethane foam.

Rubber tapping is the process by which latex is collected from a rubber tree. The latex is harvested by slicing a groove into the bark of the tree at a depth of one-quarter inch (6.4 mm) with a hooked knife and peeling back the bark. Trees must be approximately six years old and six inches (150 mm) in diameter in order to be tapped for latex.

Rubber Technology is the subject dealing with the transformation of rubbers or elastomers into useful products, such as automobile tires, rubber mats and, exercise rubber stretching bands. The materials includes latex, natural rubber, synthetic rubber and other polymeric materials, such as thermoplastic elastomers. Rubber processed through such methods are components of a wide range of items.

A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement mill. The raw milling stage of the process effectively defines the chemistry of the finished cement, and has a large effect upon the efficiency of the whole manufacturing process.

Charles Louis Rycroft was an English businessman, an important contributor to the development of the Malayan rubber industry, and a major philanthropist and benefactor of the Durrell Wildlife Conservation Trust.

David Spence was one of the pioneering rubber chemists. He helped the war effort during the Second World War by devising new ways of extracting natural rubbers from plants, and worked to improve the processing of the rubber. Over the course of his career, he worked to improve the dyeing processes for rubber products and the vulcanization of rubber, and in developing new accelerants for strengthening lower-quality natural rubber. In 1941, he became the first recipient of the Charles Goodyear Medal, awarded by the American Chemical Society.

Steel belts are a type of conveyor belt used in many industries such as food, chemical, wood processing, and transportation.

Landolphia owariensis is a species of liana from the family Apocynaceae found in tropical Africa. Latex can be extracted from this plant for the manufacture of natural rubber. Other names for this vine are eta, the white rubber vine and the Congo rubber plant. Congo rubber was a commercial rubber exported from the Congo Free State starting in 1890, most notable for its forced harvesting under conditions of great human suffering, in the Congo Free State, detailed in the 1904 Casement Report. From 1885 to 1908, millions died as a result of murder, deprivation, and disease, with population falling by millions in this period; some writers estimate this loss to be as high as 10 million people.