Related Research Articles

Lean manufacturing is a production method aimed primarily at reducing times within the production system as well as response times from suppliers and to customers. It is closely related to another concept called just-in-time manufacturing. Just-in-time manufacturing tries to match production to demand by only supplying goods which have been ordered and focuses on efficiency, productivity and reduction of "wastes" for the producer and supplier of goods. Lean manufacturing adopts the just-in-time approach and additionally focuses on reducing cycle, flow and throughput times by further eliminating activities which do not add any value for the customer. Lean manufacturing also involves people who work outside of the manufacturing process, such as in marketing and customer service.

Outsourcing is an agreement in which one company hires another company to be responsible for a planned or existing activity that is or could be done internally, and sometimes involves transferring employees and assets from one firm to another. The term outsourcing, which came from the phrase outside resourcing, originated no later than 1981. The concept, which The Economist says has "made its presence felt since the time of the Second World War", often involves the contracting of a business process, operational, and/or non-core functions, such as manufacturing, facility management, call center/call center support.

Job rotation is a technique used by some employers to rotate their employees' assigned jobs throughout their employment. Employers practice this technique for a number of reasons. It was designed to promote flexibility of employees and to keep employees interested into staying with the company/organization which employs them. There is also research that shows how job rotations help relieve the stress of employees who work in a job that requires manual labor.

An organizational structure defines how activities such as task allocation, coordination, and supervision are directed toward the achievement of organizational aims.

Job enrichment is a method of motivating employees where a job is designed to have interesting and challenging tasks which can require more skill and can increase pay.

Operations management is an area of management concerned with designing and controlling the process of production and redesigning business operations in the production of goods or services. It involves the responsibility of ensuring that business operations are efficient in terms of using as few resources as needed and effective in meeting customer requirements.

Lean thinking is a framework that aims to provide a new way to think about how to organize human activities to deliver more benefits to society and value to individuals while eliminating waste. The term “lean thinking” was coined by mechanical engineer and MIT graduate student John Krafcik in 1988, who subsequently went on to run Google's autonomous driving unit for many years. Lean thinking is a way of thinking about an activity and seeing the waste inadvertently generated by the way the process is organized. It uses the concepts of:

- Value

- Value streams

- Flow

- Pull

- Perfection

Job security is the probability that an individual will keep their job; a job with a high level of security is such that a person with the job would have a small chance of losing it. Many factors threaten job security: globalization, outsourcing, downsizing, recession, and new technology, to name a few.

Competence is the set of demonstrable characteristics and skills that enable and improve the efficiency or performance of a job. The term "competence" first appeared in an article authored by R.W. White in 1959 as a concept for performance motivation. In 1970, Craig C. Lundberg defined the concept in "Planning the Executive Development Program". The term gained traction when in 1973, David McClelland wrote a seminal paper entitled, "Testing for Competence Rather Than for Intelligence". The term was used by McClelland commissioned by the State Department, to extract characteristics common to high-performing agents of embassy, and to help them recruit and develop. It has since been popularized by Richard Boyatzis and many others, such as T.F. Gilbert (1978) who used the concept in relationship to performance improvement. Its use varies widely, which leads to considerable misunderstanding.

On-the-job training is an important topic of human resource management. It helps develop the career of the individual and the prosperous growth of the organization. On the job training is a form of training provided at the workplace. During the training, employees are familiarized with the working environment they will become part of. Employees also get a hands-on experience using machinery, equipment, tools, materials, etc. Part of on-the-job training is to face the challenges that occur during the performance of the job. An experienced employee or a manager are executing the role of the mentor who through written, or verbal instructions and demonstrations are passing on his/her knowledge and company-specific skills to the new employee. Executing the training on at the job location, rather than the classroom, creates a stress-free environment for the employees. On-the-job training is the most popular method of training not only in the United States but in most of the developed countries, such as the United Kingdom, Canada, Australia, etc. Its effectiveness is based on the use of existing workplace tools, machines, documents and equipment, and the knowledge of specialists who are working in this field. On-the-job training is easy to arrange and manage and it simplifies the process of adapting to the new workplace. On-the-job training is highly used for practical tasks. It is inexpensive, and it doesn't require special equipment that is normally used for a specific job. Upon satisfaction of completion of the training, the employer is expected to retain participants as regular employees.

Cellular manufacturing is a process of manufacturing which is a subsection of just-in-time manufacturing and lean manufacturing encompassing group technology. The goal of cellular manufacturing is to move as quickly as possible, make a wide variety of similar products, while making as little waste as possible. Cellular manufacturing involves the use of multiple "cells" in an assembly line fashion. Each of these cells is composed of one or multiple different machines which accomplish a certain task. The product moves from one cell to the next, each station completing part of the manufacturing process. Often the cells are arranged in a "U-shape" design because this allows for the overseer to move less and have the ability to more readily watch over the entire process. One of the biggest advantages of cellular manufacturing is the amount of flexibility that it has. Since most of the machines are automatic, simple changes can be made very rapidly. This allows for a variety of scaling for a product, minor changes to the overall design, and in extreme cases, entirely changing the overall design. These changes, although tedious, can be accomplished extremely quickly and precisely.

Quick response manufacturing (QRM) is an approach to manufacturing which emphasizes the beneficial effect of reducing internal and external lead times.

Lean IT is the extension of lean manufacturing and lean services principles to the development and management of information technology (IT) products and services. Its central concern, applied in the context of IT, is the elimination of waste, where waste is work that adds no value to a product or service.

Customer service training (CST) refers to teaching employees the knowledge, skills, and competencies required to increase customer satisfaction.

Competency-based recruitment is a process of recruitment based on the ability of candidates to produce anecdotes about their professional experience which can be used as evidence that the candidate has a given competency. Candidates demonstrate competencies on the application form, and then in the interview, which in this case is known as a competency-based interview.

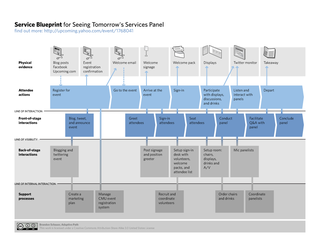

The service blueprint is a technique originally used for service design, but has also found applications in diagnosing problems with operational efficiency. The technique was first described by G. Lynn Shostack, a bank executive, in the Harvard Business Review in 1984. The service blueprint is an applied process chart which shows the service delivery process from the customer's perspective. The service blueprint has become one of the most widely used tools to manage service operations, service design and service.

A human resources management system (HRMS) or Human Resources Information System (HRIS) or Human Capital Management (HCM) is a form of Human Resources (HR) software that combines a number of systems and processes to ensure the easy management of human resources, business processes and data. Human resources software is used by businesses to combine a number of necessary HR functions, such as storing employee data, managing payroll, recruitment, benefits administration, time and attendance, employee performance management, and tracking competency and training records.

Operations management for services has the functional responsibility for producing the services of an organization and providing them directly to its customers. It specifically deals with decisions required by operations managers for simultaneous production and consumption of an intangible product. These decisions concern the process, people, information and the system that produces and delivers the service. It differs from operations management in general, since the processes of service organizations differ from those of manufacturing organizations.

The high performance organization (HPO) is a conceptual framework for organizations that leads to improved, sustainable organizational performance. It is an alternative model to the bureaucratic model known as Taylorism. There is not a clear definition of the high performance organization, but research shows that organizations that fit this model all hold a common set of characteristics. Chief among these is the ability to recognize the need to adapt to the surroundings that the organization operates in. High performance organizations can quickly and efficiently change their operating structure and practices to meet needs. These organizations focus on long term success while delivering on actionable short term goals. These organizations are flexible, customer focused, and able to work highly effectively in teams. The culture and management of these organizations support flatter hierarchies, teamwork, diversity, and adaptability to the environment which are all of paramount success to this type of organization. Compared to other organizations, high performance organizations spend much more time on continuously improving their core capabilities and invest in their workforce, leading to increased growth and performance. High performance organizations are sometimes labeled as high commitment organizations.

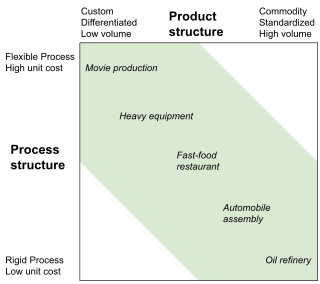

The Hayes-Wheelwright Matrix, also known as the product-process matrix, is a tool to analyze the fit between a chosen product positioning and manufacturing process.

References

- ↑ Nicholas, J. 2011. Lean Production for Competitive Advantage: A Comprehensive Guide to Lean Methodologies and Management Practices (Boca Raton, Fla.: CRC Press): 326.

- ↑ Hall. R.W. 1987. Attaining Manufacturing Excellence: Just in Time, Total Quality, Total People Involvement (Homewood, Ill., Dow Jones-Irwin): 106-7, 113-14, 127, 141-42.

- ↑ Schonberger, R. J. 1990. Building a Chain of Customers: Linking Business Functions to Create the World Class Company (New York: Free Press): 125-126.

- ↑ Suri, R. 1998. Quick Response Manufacturing: A Company-wide Approach to Reducing Lead Times (Portland, Ore.: Productivity, Inc.): 96-97, 122-123, 351, 477.

- ↑ Shuster, J.R., Zingheim, P.K. 1992. The New Pay: Linking Employee and Organizational Performance (New York: Lexington Books): 106-109.

- ↑ Sandras, W.A., Jr. 1989. Just-in-Time: Making It Happen--Unleashing the Power of Continuous Improvement (Essex Junction, Vt.: Oliver Wight Publications, Inc.): 228-229.

- ↑ Selko, A. 2008. "Automation helps Signicast stay ahead of the curve" Industry Week (July): 24.

- ↑ Schonberger, R.J. 2001. Let's Fix It! Overcoming the Crisis in Manufacturing (New York: Free Press): 20, 54, 251.