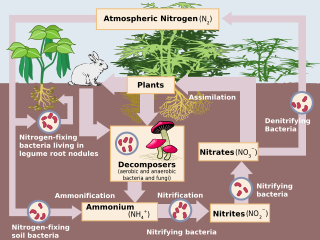

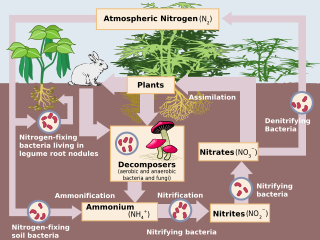

Denitrification is a microbially facilitated process where nitrate (NO3−) is reduced and ultimately produces molecular nitrogen (N2) through a series of intermediate gaseous nitrogen oxide products. Facultative anaerobic bacteria perform denitrification as a type of respiration that reduces oxidized forms of nitrogen in response to the oxidation of an electron donor such as organic matter. The preferred nitrogen electron acceptors in order of most to least thermodynamically favorable include nitrate (NO3−), nitrite (NO2−), nitric oxide (NO), nitrous oxide (N2O) finally resulting in the production of dinitrogen (N2) completing the nitrogen cycle. Denitrifying microbes require a very low oxygen concentration of less than 10%, as well as organic C for energy. Since denitrification can remove NO3−, reducing its leaching to groundwater, it can be strategically used to treat sewage or animal residues of high nitrogen content. Denitrification can leak N2O, which is an ozone-depleting substance and a greenhouse gas that can have a considerable influence on global warming.

Anammox, an abbreviation for "anaerobic ammonium oxidation", is a globally important microbial process of the nitrogen cycle that takes place in many natural environments. The bacteria mediating this process were identified in 1999, and were a great surprise for the scientific community. In the anammox reaction, nitrite and ammonium ions are converted directly into diatomic nitrogen and water.

A constructed wetland is an artificial wetland to treat sewage, greywater, stormwater runoff or industrial wastewater. It may also be designed for land reclamation after mining, or as a mitigation step for natural areas lost to land development. Constructed wetlands are engineered systems that use the natural functions of vegetation, soil, and organisms to provide secondary treatment to wastewater. The design of the constructed wetland has to be adjusted according to the type of wastewater to be treated. Constructed wetlands have been used in both centralized and decentralized wastewater systems. Primary treatment is recommended when there is a large amount of suspended solids or soluble organic matter.

Waste stabilization ponds are ponds designed and built for wastewater treatment to reduce the organic content and remove pathogens from wastewater. They are man-made depressions confined by earthen structures. Wastewater or "influent" enters on one side of the waste stabilization pond and exits on the other side as "effluent", after spending several days in the pond, during which treatment processes take place.

The activated sludgeprocess is a type of biological wastewater treatment process for treating sewage or industrial wastewaters using aeration and a biological floc composed of bacteria and protozoa. It uses air and microorganisms to biologically oxidize organic pollutants, producing a waste sludge containing the oxidized material.

Polyphosphate-accumulating organisms (PAOs) are a group of microorganisms that, under certain conditions, facilitate the removal of large amounts of phosphorus from their environments. The most studied example of this phenomenon is in polyphosphate-accumulating bacteria (PAB) found in a type of wastewater processing known as enhanced biological phosphorus removal (EBPR), however phosphate hyperaccumulation has been found to occur in other conditions such as soil and marine environments, as well as in non-bacterial organisms such as fungi and algae. PAOs accomplish this removal of phosphate by accumulating it within their cells as polyphosphate. PAOs are by no means the only microbes that can accumulate phosphate within their cells and in fact, the production of polyphosphate is a widespread ability among microbes. However, PAOs have many characteristics that other organisms that accumulate polyphosphate do not have that make them amenable to use in wastewater treatment. Specifically, in the case of classical PAOs, is the ability to consume simple carbon compounds without the presence of an external electron acceptor by generating energy from internally stored polyphosphate and glycogen. Many bacteria cannot consume carbon without an energetically favorable electron acceptor and therefore PAOs gain a selective advantage within the mixed microbial community present in the activated sludge. Therefore, wastewater treatment plants that operate for enhanced biological phosphorus removal have an anaerobic tank prior to the other tanks to give PAOs preferential access to the simple carbon compounds in the wastewater that is influent to the plant.

Secondary treatment is the removal of biodegradable organic matter from sewage or similar kinds of wastewater. The aim is to achieve a certain degree of effluent quality in a sewage treatment plant suitable for the intended disposal or reuse option. A "primary treatment" step often precedes secondary treatment, whereby physical phase separation is used to remove settleable solids. During secondary treatment, biological processes are used to remove dissolved and suspended organic matter measured as biochemical oxygen demand (BOD). These processes are performed by microorganisms in a managed aerobic or anaerobic process depending on the treatment technology. Bacteria and protozoa consume biodegradable soluble organic contaminants while reproducing to form cells of biological solids. Secondary treatment is widely used in sewage treatment and is also applicable to many agricultural and industrial wastewaters.

Sequencing batch reactors (SBR) or sequential batch reactors are a type of activated sludge process for the treatment of wastewater. SBRs treat wastewater such as sewage or output from anaerobic digesters or mechanical biological treatment facilities in batches. Oxygen is bubbled through the mixture of wastewater and activated sludge to reduce the organic matter. The treated effluent may be suitable for discharge to surface waters or possibly for use on land.

Sewage sludge treatment describes the processes used to manage and dispose of sewage sludge produced during sewage treatment. Sludge treatment is focused on reducing sludge weight and volume to reduce transportation and disposal costs, and on reducing potential health risks of disposal options. Water removal is the primary means of weight and volume reduction, while pathogen destruction is frequently accomplished through heating during thermophilic digestion, composting, or incineration. The choice of a sludge treatment method depends on the volume of sludge generated, and comparison of treatment costs required for available disposal options. Air-drying and composting may be attractive to rural communities, while limited land availability may make aerobic digestion and mechanical dewatering preferable for cities, and economies of scale may encourage energy recovery alternatives in metropolitan areas.

Aerobic granular reactors (AGR) or Aerobic granular sludge (AGS) are a community of microbial organisms, typically around 0.5-3mm in diameter, that remove carbon, nitrogen, phosphorus and other pollutants in a single sludge system. It can also be used for wastewater treatments. Aerobic granular sludge is composed of bacteria, protozoa and fungi,which allows oxygen to follow in and biologically oxidize organic pollutants. AGS is a type of wastewater treatment process for sewages and/or industrial waste treatment. AGR was first discovered by UK engineers, Edward Ardern and W.T. Lockett who were researching better ways for sewage disposal. Another scientist by the name of Dr. Gilbert Fowler, who was at the University of Manchester working on an experiment based on aeration of sewage in a bottle coated with algae. Eventually, all three scientists were able to collaborate with one another to discover AGR/AGS.

Fine bubble diffusers are a pollution control technology used to aerate wastewater for sewage treatment.

Sewage treatment is a type of wastewater treatment which aims to remove contaminants from sewage to produce an effluent that is suitable to discharge to the surrounding environment or an intended reuse application, thereby preventing water pollution from raw sewage discharges. Sewage contains wastewater from households and businesses and possibly pre-treated industrial wastewater. There are a high number of sewage treatment processes to choose from. These can range from decentralized systems to large centralized systems involving a network of pipes and pump stations which convey the sewage to a treatment plant. For cities that have a combined sewer, the sewers will also carry urban runoff (stormwater) to the sewage treatment plant. Sewage treatment often involves two main stages, called primary and secondary treatment, while advanced treatment also incorporates a tertiary treatment stage with polishing processes and nutrient removal. Secondary treatment can reduce organic matter from sewage, using aerobic or anaerobic biological processes. A so-called quarternary treatment step can also be added for the removal of organic micropollutants, such as pharmaceuticals. This has been implemented in full-scale for example in Sweden.

Membrane bioreactors are combinations of some membrane processes like microfiltration or ultrafiltration with a biological wastewater treatment process, the activated sludge process. These technologies are now widely used for municipal and industrial wastewater treatment. The two basic membrane bioreactor configurations are the submerged membrane bioreactor and the side stream membrane bioreactor. In the submerged configuration, the membrane is located inside the biological reactor and submerged in the wastewater, while in a side stream membrane bioreactor, the membrane is located outside the reactor as an additional step after biological treatment.

The biological treatment of wastewater in the sewage treatment plant is often accomplished using conventional activated sludge systems. These systems generally require large surface areas for treatment and biomass separation units due to the generally poor settling properties of the sludge. Aerobic granules are a type of sludge that can self-immobilize flocs and microorganisms into spherical and strong compact structures. The advantages of aerobic granular sludge are excellent settleability, high biomass retention, simultaneous nutrient removal and tolerance to toxicity. Recent studies show that aerobic granular sludge treatment could be a potentially good method to treat high strength wastewaters with nutrients, toxic substances.

Activated sludge model is a generic name for a group of mathematical methods to model activated sludge systems. The research in this area is coordinated by a task group of the International Water Association (IWA). Activated sludge models are used in scientific research to study biological processes in hypothetical systems. They can also be applied on full scale wastewater treatment plants for optimisation, when carefully calibrated with reference data for sludge production and nutrients in the effluent.

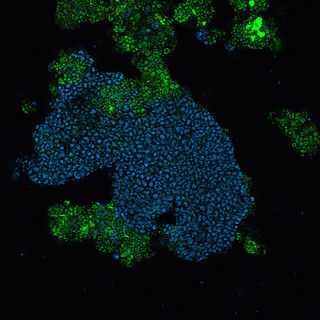

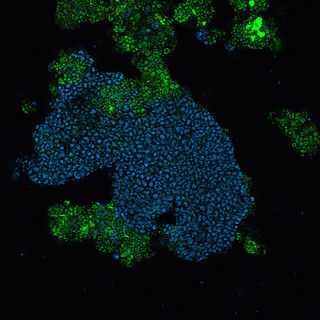

"Candidatus Accumulibacter" is an unclassified group of Betaproteobacteria that currently contains only a single member, "Candidatus Accumulibacter phosphatis". "Ca. A. phosphatis" is a common bacterial community member of wastewater treatment plants performing enhanced biological phosphorus removal and is a polyphosphate-accumulating organism. There are currently no cultured representatives, however due to the importance of "Ca. A. phosphatis" in the biotechnology industry there has been much research into the physiology of these bacteria.

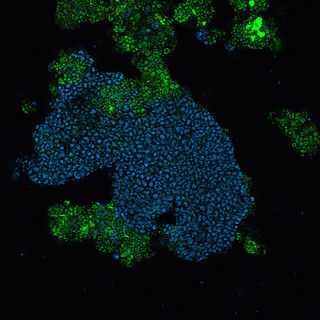

Candidatus Accumulibacter phosphatis (CAP) is an unclassified type of Betaproteobacteria that is a common bacterial community member of sewage treatment and wastewater treatment plants performing enhanced biological phosphorus removal (EBPR) and is a polyphosphate-accumulating organism. The role of CAP in EBPR was elucidated using culture-independent approaches such as 16S rRNA clone banks that showed the Betaproteobacteria dominated lab-scale EBPR reactors. Further work using clone banks and fluorescence in situ hybridization identified a group of bacteria, closely related to Rhodocyclus as the dominant member of lab-scale communities.

The adsorption/bio-oxidation process is a two-stage modification of the activated sludge process used for wastewater treatment. It consists of a high-loaded A-stage and low-loaded B-stage. The process is operated without a primary clarifier, with the A-stage being an open dynamic biological system. Both stages have separate settling tanks and sludge recycling lines, thus maintaining unique microbial communities in both reactors.

Moving bed biofilm reactor (MBBR) is a type of wastewater treatment process that was first invented by Professor Hallvard Ødegaard at Norwegian University of Science and Technology in the late 1980s. The process takes place in an aeration tank with plastic carriers that a biofilm can grow on. The compact size and cheap wastewater treatment costs offers many advantages for the system. The main objective of using MBBR being water reuse and nutrient removal or recovery. In theory, wastewater will be no longer considered waste, it can be considered a resource.