Gates Iron Works was a U.S. manufacturer of machinery, specialized in rock and cement milling equipment. It was based in Chicago and merged into the Allis-Chalmers Company in 1901

Gates Iron Works was a U.S. manufacturer of machinery, specialized in rock and cement milling equipment. It was based in Chicago and merged into the Allis-Chalmers Company in 1901

Thomas Chalmers was a Scottish immigrant to America who came to the U.S. about 1842. By 1844 he was at Chicago, Illinois and had found work with P.W. Gates, whose foundry and blacksmithing shops produced plows, wagons, and flour-milling equipment. [2]

The Gates firm "built the first steam-operated sawmill in the country at a time when Chicago was the leading producer of milled lumber in the country." [2]

In 1872, Thomas Chalmers founded the Fraser & Chalmers firm to manufacture mining machinery, boilers, and pumps. [3] By 1880 steam engines were part of the product line and by 1890, the firm had become one of the world's largest manufacturers of mining equipment. [3] Thomas Chalmers's son, William James Chalmers, was president of the company from circa 1890 to 1901. Meanwhile, the Gates Iron Works, with Chalmers family involvement, had become a manufacturer of crushers, pulverizers, and other rock and cement milling equipment.

Another Scottish immigrant family, the Dickson family, came to Canada and the U.S. in the 1830s. By 1852, they had organized a small machine shop and foundry (Dickson & Company) in Scranton, Pennsylvania. In 1856 Thomas Dickson became its president, and in 1862 the firm incorporated as the Dickson Manufacturing Company. By 1900 they were building boilers, steam engines, locomotives, internal combustion engines, blowers, and air compressors.

By 1901 the principals of the Edward P. Allis, Fraser & Chalmers, and Gates firms had decided to merge their companies. Edwin Reynolds believed Allis could control the industrial engine business. [4] In May 1901 the Allis-Chalmers Company was formed. [4]

It acquired Dickson's industrial engine business. Dickson's locomotive business was rolled into the new locomotive consolidation, the American Locomotive Company (ALCO).

Vulcan Iron Works was the name of several iron foundries in both England and the United States during the Industrial Revolution and, in one case, lasting until the mid-20th century. Vulcan, the Roman god of fire and smithery, was a popular namesake for these foundries.

Allis-Chalmers was a U.S. manufacturer of machinery for various industries. Its business lines included agricultural equipment, construction equipment, power generation and power transmission equipment, and machinery for use in industrial settings such as factories, flour mills, sawmills, textile mills, steel mills, refineries, mines, and ore mills.

William Foster & Co Ltd was an agricultural machinery company based in Lincoln, Lincolnshire, England often called "Fosters of Lincoln." The company can be traced back to 1846, when William Foster purchased a flour mill in Lincoln. William Foster then proceeded to start small scale manufacturing of mill machinery and threshing machinery. The mill was converted to an iron foundry by 1856, thus becoming the original Wellington Foundry. By 1899 the works had moved to the Wellington foundry in New Boultham and the original works were then occupied by William Rainforth. During the First World War Fosters built some of the first tanks for the British Army.

Dickson Manufacturing Company was an American manufacturer of boilers, blast furnaces and steam engines used in various industries but most known in railway steam locomotives. The company also designed and constructed steam powered mine cable hoists. It was founded in Scranton, Pennsylvania by Thomas Dickson in 1856. In total, the company produced 1,334 steam locomotives until it was taken over by ALCO in 1901.

De Winton & Co (1854–1901) were engineers in Caernarfon, Wales. They built, amongst other things, vertical boilered narrow gauge locomotives for use in Welsh slate mines and other industrial settings. At least six De Winton locomotives have been preserved. But these quarry tramway locomotives, for which in the 21st century they are largely remembered, were just a small part of this company's engineering output.

Haigh Foundry was an ironworks and foundry in Haigh, Lancashire, which was notable for the manufacture of early steam locomotives.

B. Hick and Sons, subsequently Hick, Hargreaves & Co, was a British engineering company based at the Soho Ironworks in Bolton, England. Benjamin Hick, a partner in Rothwell, Hick and Rothwell, later Rothwell, Hick & Co., set up the company in partnership with two of his sons, John (1815–1894) and Benjamin (1818–1845) in 1833.

The Advance-Rumely Company of La Porte, Indiana was an American pioneering producer of many types of agricultural machinery, most notably threshing machines and large tractors. Started in 1853 manufacturing threshers and later moved on to steam engines. Allis-Chalmers Manufacturing Co. purchased Advance-Rumley in 1931. The company's main works would become what was later known as the "La Porte plant".

A portable engine is an engine, either a steam engine or an internal combustion engine, that sits in one place while operating, but is portable and thus can be easily moved from one work site to another. Mounted on wheels or skids, it is either towed to the work site or moves there via self-propulsion.

Thomas Green & Son, Ltd. were engineers who manufactured a wide range of products at the Smithfield Foundry, Leeds, United Kingdom

Scott Brothers Limited was an engineering firm in Christchurch, New Zealand.

The Oliver Farm Equipment Company was an American farm equipment manufacturer from the 20th century. It was formed as a result of a 1929 merger of four companies: the American Seeding Machine Company of Richmond, Indiana; Oliver Chilled Plow Works of South Bend, Indiana; Hart-Parr Tractor Company of Charles City, Iowa; and Nichols and Shepard Company of Battle Creek, Michigan.

Mather & Platt is the name of several large engineering firms in Europe, South Africa and Asia that are subsidiaries of Wilo SE, Germany or were founded by former employees. The original company was founded in the Newton Heath area of Manchester, England, where it was a major employer. That firm continues as a food processing and packaging business, trading as M & P Engineering in Trafford Park, Manchester.

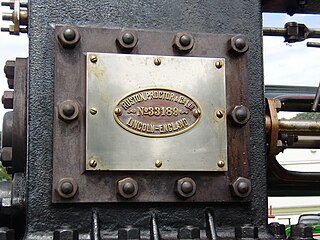

Ruston, Proctor and Company was established in Lincoln, England in 1857, and were manufacturers of steam tractors and engines. They later became Rustons and then Ruston & Hornsby.

Buda Engine was founded in 1881 by George Chalender in Buda, Illinois, to make equipment for railways. Later based in Harvey, Illinois, Buda from 1910 manufactured engines for industrial, truck, and marine applications. Early Buda engines were gasoline fueled. Later, diesel engines were introduced, utilizing proprietary Lanova cylinder head designs, injection pumps and nozzles. These were known as Buda-Lanova diesel engines. Buda Engine Company was acquired by Allis-Chalmers in 1953. The Buda-Lanova models were re-christened "Allis-Chalmers diesel".

John Cockerill, formerly Cockerill Maintenance & Ingénierie (CMI), is a mechanical engineering group headquartered in Seraing, Belgium. It produces machinery for steel plants, industrial heat recovery equipment and boilers, as well as shunting locomotives and military equipment.

W & J Galloway and Sons was a British manufacturer of steam engines and boilers based in Manchester, England. The firm was established in 1835 as a partnership of two brothers, William and John Galloway. The partnership expanded to encompass their sons and in 1889 it was restructured as a limited liability company. It ceased trading in 1932.

Edward Phelps Allis was an American businessman who founded the Edward P. Allis Company, a manufacturer of milling and mining equipment, steam engines, and other large-scale capital equipment. He was a notable ideologue in the Greenback Movement, running for governor of Wisconsin as a candidate of the Greenback Party. About a decade after his death, his company merged with others to form the Allis-Chalmers Manufacturing Company. In 1883, Allis was elected a fellow of the American Society of Civil Engineers.

Phoenix Foundry, often printed as Phœnix, was an engineering company in Auckland from 1861 to 1952. By 1900 it was on the verge of bankruptcy, but also Auckland's largest engineering works, supplying a wide range of goods and often leading in the design of equipment used to exploit the country's resources, such as timber and flax mills, crushers for gold ore and locomotives, pumps, cement and gas works and steamers. The foundry started with engineer, George Fraser, and a handful of employees, but grew to employ hundreds and operated under several names, including Fraser and Tinne and George Fraser & Sons Ltd.