Gimbaled thrust is the system of thrust vectoring used in most rockets, including the Space Shuttle, the Saturn V lunar rockets, and the Falcon 9.

Gimbaled thrust is the system of thrust vectoring used in most rockets, including the Space Shuttle, the Saturn V lunar rockets, and the Falcon 9.

In a gimbaled thrust system, the engine or just the exhaust nozzle of the rocket can be swiveled on two axes (pitch and yaw) from side to side. As the nozzle is moved, the direction of the thrust is changed relative to the center of gravity of the rocket.

The diagram illustrates three cases. The middle rocket shows the straight-line flight configuration in which the direction of thrust is along the center line of the rocket and through the center of gravity of the rocket. On the rocket at the left, the nozzle has been deflected to the left and the thrust line is now inclined to the rocket center line at an angle called the gimbal angle. Since the thrust no longer passes through the center of gravity, a torque is generated about the center of gravity and the nose of the rocket turns to the left. If the nozzle is gimbaled back along the center line, the rocket will move to the left. On the rocket at the right, the nozzle has been deflected to the right and the nose is moved to the right.

Thrust vectoring for many liquid rockets is achieved by gimbaling the whole engine. This involves moving the entire combustion chamber and outer engine bell as on the Titan II's twin first-stage motors, or even the entire engine assembly including the related fuel and oxidizer pumps. The Saturn V and the Space Shuttle used gimbaled engines. [1]

A later method developed for solid propellant ballistic missiles achieves thrust vectoring by deflecting only the nozzle of the rocket using electric actuators or hydraulic cylinders. The nozzle is attached to the missile via a ball joint with a hole in the centre, or a flexible seal made of a thermally resistant material, the latter generally requiring more torque and a higher power actuation system. The Trident C4 and D5 systems are controlled via hydraulically actuated nozzle. The STS SRBs used gimbaled nozzles. [2]

A rocket is a vehicle that uses jet propulsion to accelerate without using the surrounding air. A rocket engine produces thrust by reaction to exhaust expelled at high speed. Rocket engines work entirely from propellant carried within the vehicle; therefore a rocket can fly in the vacuum of space. Rockets work more efficiently in a vacuum and incur a loss of thrust due to the opposing pressure of the atmosphere.

A solid-propellant rocket or solid rocket is a rocket with a rocket engine that uses solid propellants (fuel/oxidizer). The earliest rockets were solid-fuel rockets powered by gunpowder; they were used in warfare by the Chinese, Persians, Mongols, and Indians as early as the 13th century.

A rocket engine uses stored rocket propellants as the reaction mass for forming a high-speed propulsive jet of fluid, usually high-temperature gas. Rocket engines are reaction engines, producing thrust by ejecting mass rearward, in accordance with Newton's third law. Most rocket engines use the combustion of reactive chemicals to supply the necessary energy, but non-combusting forms such as cold gas thrusters and nuclear thermal rockets also exist. Vehicles propelled by rocket engines are commonly called rockets. Rocket vehicles carry their own oxidiser, unlike most combustion engines, so rocket engines can be used in a vacuum to propel spacecraft and ballistic missiles.

The Apollo spacecraft was composed of three parts designed to accomplish the American Apollo program's goal of landing astronauts on the Moon by the end of the 1960s and returning them safely to Earth. The expendable (single-use) spacecraft consisted of a combined command and service module (CSM) and an Apollo Lunar Module (LM). Two additional components complemented the spacecraft stack for space vehicle assembly: a spacecraft–LM adapter (SLA) designed to shield the LM from the aerodynamic stress of launch and to connect the CSM to the Saturn launch vehicle and a launch escape system (LES) to carry the crew in the command module safely away from the launch vehicle in the event of a launch emergency.

The Space Shuttle Solid Rocket Booster (SRB) was the first solid-propellant rocket to be used for primary propulsion on a vehicle used for human spaceflight. A pair of these provided 85% of the Space Shuttle's thrust at liftoff and for the first two minutes of ascent. After burnout, they were jettisoned and parachuted into the Atlantic Ocean where they were recovered, examined, refurbished, and reused.

Thrust vectoring, also known as thrust vector control (TVC), is the ability of an aircraft, rocket, or other vehicle to manipulate the direction of the thrust from its engine(s) or motor(s) to control the attitude or angular velocity of the vehicle.

The Aerojet Rocketdyne RS-25, also known as the Space Shuttle Main Engine (SSME), is a liquid-fuel cryogenic rocket engine that was used on NASA's Space Shuttle and is currently used on the Space Launch System (SLS).

The J-2 is a liquid-fuel cryogenic rocket engine used on NASA's Saturn IB and Saturn V launch vehicles. Built in the U.S. by Rocketdyne, the J-2 burned cryogenic liquid hydrogen (LH2) and liquid oxygen (LOX) propellants, with each engine producing 1,033.1 kN (232,250 lbf) of thrust in vacuum. The engine's preliminary design dates back to recommendations of the 1959 Silverstein Committee. Rocketdyne won approval to develop the J-2 in June 1960 and the first flight, AS-201, occurred on 26 February 1966. The J-2 underwent several minor upgrades over its operational history to improve the engine's performance, with two major upgrade programs, the de Laval nozzle-type J-2S and aerospike-type J-2T, which were cancelled after the conclusion of the Apollo program.

Aries is an American sounding rocket and target rocket, developed by Space Vector Corporation from retired LGM-30 Minuteman I intercontinental ballistic missile (ICBM) stages for use by the United States Air Force and NASA. Taken over by Orbital Sciences Corporation, Aries, as the Target Test Vehicle, remains in use.

This is an alphabetical list of articles pertaining specifically to aerospace engineering. For a broad overview of engineering, see List of engineering topics. For biographies, see List of engineers.

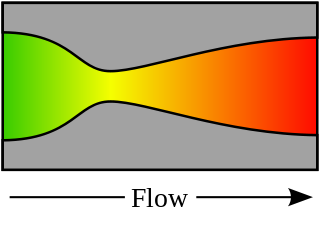

A rocket engine nozzle is a propelling nozzle used in a rocket engine to expand and accelerate combustion products to high supersonic velocities.

The Inertial Upper Stage (IUS), originally designated the Interim Upper Stage, was a two-stage, solid-fueled space launch system developed by Boeing for the United States Air Force beginning in 1976 for raising payloads from low Earth orbit to higher orbits or interplanetary trajectories following launch aboard a Titan 34D or Titan IV rocket as its upper stage, or from the payload bay of the Space Shuttle as a space tug.

Ares I-X was the first-stage prototype and design concept demonstrator of Ares I, a launch system for human spaceflight developed by the National Aeronautics and Space Administration (NASA). Ares I-X was successfully launched on October 28, 2009. The project cost was $445 million.

A gravity turn or zero-lift turn is a maneuver used in launching a spacecraft into, or descending from, an orbit around a celestial body such as a planet or a moon. It is a trajectory optimization that uses gravity to steer the vehicle onto its desired trajectory. It offers two main advantages over a trajectory controlled solely through the vehicle's own thrust. First, the thrust is not used to change the spacecraft's direction, so more of it is used to accelerate the vehicle into orbit. Second, and more importantly, during the initial ascent phase the vehicle can maintain low or even zero angle of attack. This minimizes transverse aerodynamic stress on the launch vehicle, allowing for a lighter launch vehicle.

A roll program or tilt maneuver is an aerodynamic maneuver that alters the attitude of a vertically launched space launch vehicle. The maneuver is used to place the spacecraft on a proper heading toward its intended orbit. It often consists of a partial rotation around the vehicle's vertical axis ("roll") followed by tilting the vehicle ("pitch") to follow the proper gravity turn and/or to improve aerodynamics.

Fastrac was a turbo pump-fed, liquid rocket engine. The engine was designed by NASA as part of the low cost X-34 Reusable Launch Vehicle (RLV) and as part of the Low Cost Booster Technology project. This engine was later known as the MC-1 engine when it was merged into the X-34 project.

The Star is a family of US solid-propellant rocket motors originally developed by Thiokol and used by many space propulsion and launch vehicle stages. They are used almost exclusively as an upper stage, often as an apogee kick motor.

The Bell Aerosystems Company XLR81 was an American liquid-propellant rocket engine, which was used on the Agena upper stage. It burned UDMH and RFNA fed by a turbopump in a fuel rich gas generator cycle. The turbopump had a single turbine with a gearbox to transmit power to the oxidizer and fuel pumps. The thrust chamber was all-aluminum, and regeneratively cooled by oxidizer flowing through gun-drilled passages in the combustion chamber and throat walls. The nozzle was a titanium radiatively cooled extension. The engine was mounted on a hydraulic actuated gimbal which enabled thrust vectoring to control pitch and yaw. Engine thrust and mixture ratio were controlled by cavitating flow venturis on the gas generator flow circuit. Engine start was achieved by solid propellant start cartridge.

UA120 was a family of American solid rocket boosters, manufactured by the Chemical Systems Division of United Aircraft. Several variants existed, with a varying number of segments.

The Solid Rocket Motor Upgrade (SRMU) was a solid rocket motor that was used as a booster on the Titan IVB launch vehicle. Developed by Hercules, it was intended to be a high-performance, low-cost upgrade to the UA1207 boosters previously used on Titan IV. Wound from carbon-fibre-reinforced polymer and burning a hydroxyl-terminated polybutadiene-bound ammonium perchlorate composite propellant, it was an ambitious upgrade building on Hercules' experience developing a filament-wound case for the Space Shuttle SRB. Originally intended to fly in 1990, it instead first flew in 1997 due to a protracted development and lack of demand. The SRMU performed successfully on all of its flights.