A tablet is a pharmaceutical oral dosage form or solid unit dosage form. Tablets may be defined as the solid unit dosage form of medication with suitable excipients. It comprises a mixture of active substances and excipients, usually in powder form, that are pressed or compacted into a solid dose. The main advantages of tablets are that they ensure a consistent dose of medicine that is easy to consume.

Spray drying is a method of forming a dry powder from a liquid or slurry by rapidly drying with a hot gas. This is the preferred method of drying of many thermally-sensitive materials such as foods and pharmaceuticals, or materials which may require extremely consistent, fine particle size. Air is most commonly used as the heated drying medium; however, nitrogen may be used if the liquid is flammable or if the product is oxygen-sensitive.

Paper engineering is a branch of engineering that deals with the usage of physical science and life sciences in conjunction with mathematics as applied to the converting of raw materials into useful paper products and co-products. The field applies various principles in process engineering and unit operations to the manufacture of paper, chemicals, energy and related materials. The following timeline shows some of the key steps in the development of the science of chemical and bioprocess engineering:

A chemical plant is an industrial process plant that manufactures chemicals, usually on a large scale. The general objective of a chemical plant is to create new material wealth via the chemical or biological transformation and or separation of materials. Chemical plants use specialized equipment, units, and technology in the manufacturing process. Other kinds of plants, such as polymer, pharmaceutical, food, and some beverage production facilities, power plants, oil refineries or other refineries, natural gas processing and biochemical plants, water and wastewater treatment, and pollution control equipment use many technologies that have similarities to chemical plant technology such as fluid systems and chemical reactor systems. Some would consider an oil refinery or a pharmaceutical or polymer manufacturer to be effectively a chemical plant.

A pilot plant is a pre-commercial production system that employs new production technology and/or produces small volumes of new technology-based products, mainly for the purpose of learning about the new technology. The knowledge obtained is then used for design of full-scale production systems and commercial products, as well as for identification of further research objectives and support of investment decisions. Other (non-technical) purposes include gaining public support for new technologies and questioning government regulations. Pilot plant is a relative term in the sense that pilot plants are typically smaller than full-scale production plants, but are built in a range of sizes. Also, as pilot plants are intended for learning, they typically are more flexible, possibly at the expense of economy. Some pilot plants are built in laboratories using stock lab equipment, while others require substantial engineering efforts, cost millions of dollars, and are custom-assembled and fabricated from process equipment, instrumentation and piping. They can also be used to train personnel for a full-scale plant. Pilot plants tend to be smaller compared to demonstration plants.

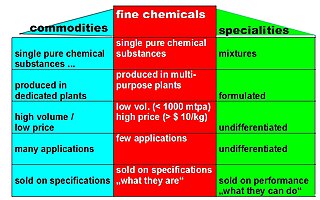

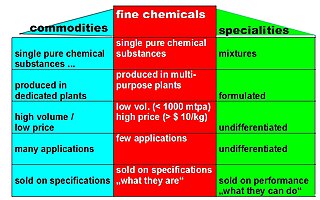

In chemistry, fine chemicals are complex, single, pure chemical substances, produced in limited quantities in multipurpose plants by multistep batch chemical or biotechnological processes. They are described by exacting specifications, used for further processing within the chemical industry and sold for more than $10/kg. The class of fine chemicals is subdivided either on the basis of the added value, or the type of business transaction, namely standard or exclusive products.

SAMSON AG, founded in 1907 is a German control valve manufacturing company headquartered in Frankfurt. It develops systems and products that can control all types of fluid. Its product line includes valves, self-operating regulators, automation systems, sensors, thermostats, and digital devices, among others.

Pelletizing is the process of compressing or molding a material into the shape of a pellet. A wide range of different materials are pelletized including chemicals, iron ore, animal compound feed, plastics, waste materials, and more. The process is considered an excellent option for the storage and transport of said materials. The technology is widely used in the powder metallurgy engineering and medicine industries.

A high-shear mixer disperses, or transports, one phase or ingredient into a main continuous phase (liquid), with which it would normally be immiscible. A rotor or impeller, together with a stationary component known as a stator, or an array of rotors and stators, is used either in a tank containing the solution to be mixed, or in a pipe through which the solution passes, to create shear. A high-shear mixer can be used to create emulsions, suspensions, lyosols, and granular products. It is used in the adhesives, chemical, cosmetic, food, pharmaceutical, and plastics industries for emulsification, homogenization, particle size reduction, and dispersion.

Mitsui & Co., Ltd. is one of the largest sogo shosha in Japan; it is part of the Mitsui Group.

Graco Inc. is an American industrial company specializing in the development and manufacturing of fluid-handling systems and products. The company is headquartered in Minneapolis, Minnesota, and markets its products to customers worldwide.

Pharmaceutical manufacturing is the process of industrial-scale synthesis of pharmaceutical drugs as part of the pharmaceutical industry. The process of drug manufacturing can be broken down into a series of unit operations, such as milling, granulation, coating, tablet pressing, and others.

Granulation is the process of forming grains or granules from a powdery or solid substance, producing a granular material. It is applied in several technological processes in the chemical and pharmaceutical industries. Typically, granulation involves agglomeration of fine particles into larger granules, typically of size range between 0.2 and 4.0 mm depending on their subsequent use. Less commonly, it involves shredding or grinding solid material into finer granules or pellets.

Tableting is a method of pressing medicine or candy into tablets. Confectionery manufacture shares many similarities with pharmaceutical production.

The Bühler Holding AG is a Swiss multinational plant equipment manufacturer based in Uzwil, Switzerland. It is known for plant and equipment and related services for processing foods and manufacturing advanced materials. The organization holds leading market positions worldwide in the fields of technology as well as processes for transforming grain into flour and animal feeds, producing pasta and chocolate, and manufacturing die cast components. The core technologies of the Group are in the field of mechanical and thermal process engineering.

Specialty chemicals are particular chemical products which provide a wide variety of effects on which many other industry sectors rely. Some of the categories of speciality chemicals are adhesives, agrichemicals, cleaning materials, colors, cosmetic additives, construction chemicals, elastomers, flavors, food additives, fragrances, industrial gases, lubricants, paints, polymers, surfactants, and textile auxiliaries. Other industrial sectors such as automotive, aerospace, food, cosmetics, agriculture, manufacturing, and textiles are highly dependent on such products.

Vibratory Fluidized Bed (VFB) is a type of fluidized bed where the mechanical vibration enhances the performance of fluidization process. Since the first discovery of vibratory fluidized bed, its vibration properties proves to be more efficient in dealing with fine particles which appears to be very difficult to achieve with normal fluidized bed. Even though numerous publications and its popularity in industrial applications, the knowledge about vibratory dynamics and properties are very limited. Future research and development are needed to further improve this technology to bring it to another level.

EPIC Systems, Inc. is an American multi-discipline engineering and fabrication firm located in Saint Louis, Missouri. EPIC's name is an acronym which stands for “Electrical, Process, Instrumentation and Control Systems”. EPIC was founded in 1995 as a privately held automation firm and has grown to include divisions for complete modular process plants and systems, integrated packaging and assembly lines, custom machinery manufacturing, and machine vision system integration.

L.J. Institute of Pharmacy, commonly referred as LJIP, is a private management institute located in Ahmedabad, Gujarat, India. The institute is approved by All India Council for Technical Education (AICTE) and Pharmacy Council of India (PCI) and is the part of L.J. Group of Institutes managed by Lok Jagruti Kendra (LJK) Trust. The institute is affiliated to Gujarat Technological University (GTU). The institute is approved by Department of Scientific and Industrial Research (DSIR), Ministry of Science and Technology, Govt. of India as Scientific and Industrial Research Organization (SIRO).

Agglomerated food powder is a unit operation during which native particles are assembled to form bigger agglomerates, in which the original particle can still be distinguished. Agglomeration can be achieved through processes that use liquid as a binder or methods that do not involve any binder.