A pulley is a wheel on an axle or shaft that is designed to support movement and change of direction of a taut cable or belt, or transfer of power between the shaft and cable or belt. In the case of a pulley supported by a frame or shell that does not transfer power to a shaft, but is used to guide the cable or exert a force, the supporting shell is called a block, and the pulley may be called a sheave.

A flange is a protruded ridge, lip or rim, either external or internal, that serves to increase strength ; for easy attachment/transfer of contact force with another object ; or for stabilizing and guiding the movements of a machine or its parts. The term "flange" is also used for a kind of tool used to form flanges.

Tongue and groove is a method of fitting similar objects together, edge to edge, used mainly with wood, in flooring, parquetry, panelling, and similar constructions. Tongue and groove joints allow two flat pieces to be joined strongly together to make a single flat surface. Before plywood became common, tongue and groove boards were also used for sheathing buildings and to construct concrete formwork.

The humerus is a long bone in the arm that runs from the shoulder to the elbow. It connects the scapula and the two bones of the lower arm, the radius and ulna, and consists of three sections. The humeral upper extremity consists of a rounded head, a narrow neck, and two short processes. The body is cylindrical in its upper portion, and more prismatic below. The lower extremity consists of 2 epicondyles, 2 processes, and 3 fossae. As well as its true anatomical neck, the constriction below the greater and lesser tubercles of the humerus is referred to as its surgical neck due to its tendency to fracture, thus often becoming the focus of surgeons.

A gasket is a mechanical seal which fills the space between two or more mating surfaces, generally to prevent leakage from or into the joined objects while under compression. It is a deformable material that is used to create a static seal and maintain that seal under various operating conditions in a mechanical assembly.

A wheellock, wheel-lock or wheel lock is a friction-wheel mechanism which creates a spark that causes a firearm to fire. It was the next major development in firearms technology after the matchlock and the first self-igniting firearm. Its name is from its rotating steel wheel to provide ignition. Developed in Europe around 1500, it was used alongside the matchlock and was later superseded by the snaplock (1540s), the snaphance (1560s) and the flintlock.

In mathematics, an Apollonian gasket or Apollonian net is a fractal generated by starting with a triple of circles, each tangent to the other two, and successively filling in more circles, each tangent to another three. It is named after Greek mathematician Apollonius of Perga.

The maxillary first molar is the human tooth located laterally from both the maxillary second premolars of the mouth but mesial from both maxillary second molars.

A rut is a depression or groove worn into a road or path by the travel of wheels or skis. Ruts can be formed by wear, as from studded snow tires common in cold climate areas, or they can form through the deformation of the asphalt concrete, pavement or subbase material. In modern roads the main cause is heavily loaded trucks. These heavy loaded trucks imprint their tire impressions on roads over time, causing ruts. Rut is a common pavement distress and is often used in pavement performance modeling.

Slot, the slot or Slots may refer to:

A vacuum flange is a flange at the end of a tube used to connect vacuum chambers, tubing and vacuum pumps to each other. Vacuum flanges are used for scientific and industrial applications to allow various pieces of equipment to interact via physical connections and for vacuum maintenance, monitoring, and manipulation from outside a vacuum's chamber. Several flange standards exist with differences in ultimate attainable pressure, size, and ease of attachment.

River bifurcation occurs when a river flowing in a single stream separates into two or more separate streams which then continue downstream. Some rivers form complex networks of distributaries, typically in their deltas. If the streams eventually merge again or empty into the same body of water, then the bifurcation forms a river island.

Victaulic is a developer and producer of mechanical pipe joining systems headquartered in Easton, Pennsylvania, and is the originator of the grooved pipe couplings joining system. Victaulic has 15 major manufacturing facilities, 28 branches, and over 3600 employees worldwide. John F. Malloy has served as CEO since 2002. Control of the company is split between Margaret "Muffie" Bancroft and Pierre D'Arenberg.

A fitting or adapter is used in pipe systems to connect straight sections of pipe or tube, adapt to different sizes or shapes, and for other purposes such as regulating fluid flow. These fittings are used in plumbing to manipulate the conveyance of water, gas, or liquid waste in domestic or commercial environments, within a system of pipes or tubes.

This glossary of woodworking lists a number of specialized terms and concepts used in woodworking, carpentry, and related disciplines.

The rail profile is the cross sectional shape of a railway rail, perpendicular to its length.

A railway or railroad is a track where the vehicle travels over two parallel steel bars, called rails. The rails support and guide the wheels of the vehicles, which are traditionally either trains or trams. Modern light rail is a relatively new innovation which combines aspects of those two modes of transport. However fundamental differences in the track and wheel design are important, especially where trams or light railways and trains have to share a section of track, as sometimes happens in congested areas.

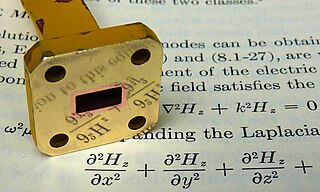

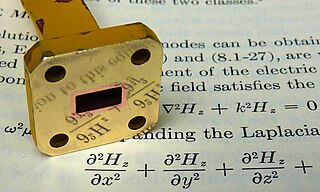

A waveguide flange is a connector for joining sections of waveguide, and is essentially the same as a pipe flange—a waveguide, in the context of this article, being a hollow metal conduit for microwave energy. The connecting face of the flange is either square, circular or, rectangular. The connection between a pair of flanges is usually made with four or more bolts, though alternative mechanisms, such as a threaded collar, may be used where there is a need for rapid assembly and disassembly. Dowel pins are sometimes used in addition to bolts, to ensure accurate alignment, particularly for very small waveguides.

Implant induction welding is a joining method used in plastic manufacturing. The welding process uses an induction coil to excite and heat electromagnetically susceptible material at the joint interface and melt the thermoplastic. The susceptible material can be contained in a gasket placed between the welding surface, or within the actual components of a composite material. Its usage is common for large, unusually shaped, or delicate parts that would be difficult to weld through other methods.