Related Research Articles

A system on a chip, also written as system-on-a-chip and system-on-chip, is an integrated circuit that integrates all or most components of a computer or other electronic system. These components almost always include a central processing unit (CPU), memory interfaces, on-chip input/output devices, input/output interfaces, and secondary storage interfaces, often alongside other components such as radio modems and a graphics processing unit (GPU) – all on a single substrate or microchip. It may contain digital, analog, mixed-signal, and often radio frequency signal processing functions.

An oil refinery or petroleum refinery is an industrial process plant where petroleum is transformed and refined into useful products such as gasoline (petrol), diesel fuel, asphalt base, fuel oils, heating oil, kerosene, liquefied petroleum gas and petroleum naphtha. Petrochemicals feedstock like ethylene and propylene can also be produced directly by cracking crude oil without the need of using refined products of crude oil such as naphtha. The crude oil feedstock has typically been processed by an oil production plant. There is usually an oil depot at or near an oil refinery for the storage of incoming crude oil feedstock as well as bulk liquid products. In 2020, the total capacity of global refineries for crude oil was about 101.2 million barrels per day.

Distributed generation, also distributed energy, on-site generation (OSG), or district/decentralized energy, is electrical generation and storage performed by a variety of small, grid-connected or distribution system-connected devices referred to as distributed energy resources (DER).

'Gas chromatography (') is a common type of chromatography used in analytical chemistry for separating and analyzing compounds that can be vaporized without decomposition. Typical uses of GC include testing the purity of a particular substance, or separating the different components of a mixture. In preparative chromatography, GC can be used to prepare pure compounds from a mixture.

Process engineering is the understanding and application of the fundamental principles and laws of nature that allow humans to transform raw material and energy into products that are useful to society, at an industrial level. By taking advantage of the driving forces of nature such as pressure, temperature and concentration gradients, as well as the law of conservation of mass, process engineers can develop methods to synthesize and purify large quantities of desired chemical products. Process engineering focuses on the design, operation, control, optimization and intensification of chemical, physical, and biological processes. Process engineering encompasses a vast range of industries, such as agriculture, automotive, biotechnical, chemical, food, material development, mining, nuclear, petrochemical, pharmaceutical, and software development. The application of systematic computer-based methods to process engineering is "process systems engineering".

The hydrogen economy is using hydrogen to decarbonize economic sectors which are hard to electrify, essentially, the "hard-to-abate" sectors such as cement, steel, long-haul transport etc. In order to phase out fossil fuels and limit climate change, hydrogen can be created from water using renewable sources such as wind and solar, and its combustion only releases water vapor to the atmosphere.

Event processing is a method of tracking and analyzing (processing) streams of information (data) about things that happen (events), and deriving a conclusion from them. Complex event processing, or CEP, consists of a set of concepts and techniques developed in the early 1990s for processing real-time events and extracting information from event streams as they arrive. The goal of complex event processing is to identify meaningful events in real-time situations and respond to them as quickly as possible.

Grid energy storage is a collection of methods used for energy storage on a large scale within an electrical power grid. Electrical energy is stored during times when electricity is plentiful and inexpensive or when demand is low, and later returned to the grid when demand is high, and electricity prices tend to be higher.

Pressure swing adsorption (PSA) is a technique used to separate some gas species from a mixture of gases under pressure according to the species' molecular characteristics and affinity for an adsorbent material. It operates at near-ambient temperature and significantly differs from the cryogenic distillation commonly used to separate gases. Selective adsorbent materials are used as trapping material, preferentially adsorbing the target gas species at high pressure. The process then swings to low pressure to desorb the adsorbed gas.

Hydrogen production is the family of industrial methods for generating hydrogen gas. As of 2020, the majority of hydrogen (∼95%) is produced from fossil fuels by steam reforming of natural gas and other light hydrocarbons, partial oxidation of heavier hydrocarbons, and coal gasification. Other methods of hydrogen production include biomass gasification, zero-CO2-emission methane pyrolysis, and electrolysis of water. The latter processes, methane pyrolysis as well as water electrolysis can be done directly with any source of electricity, such as solar power.

Process integration is a term in chemical engineering which has two possible meanings.

- A holistic approach to process design which emphasizes the unity of the process and considers the interactions between different unit operations from the outset, rather than optimising them separately. This can also be called integrated process design or process synthesis. El-Halwagi and Smith (2005) describe the approach well. An important first step is often product design which develops the specification for the product to fulfil its required purpose.

- Pinch analysis, a technique for designing a process to minimise energy consumption and maximise heat recovery, also known as heat integration, energy integration or pinch technology. The technique calculates thermodynamically attainable energy targets for a given process and identifies how to achieve them. A key insight is the pinch temperature, which is the most constrained point in the process. The most detailed explanation of the techniques is by Linnhoff et al. (1982), Shenoy (1995), Kemp (2006) and Kemp and Lim (2020), and it also features strongly in Smith (2005). This definition reflects the fact that the first major success for process integration was the thermal pinch analysis addressing energy problems and pioneered by Linnhoff and co-workers. Later, other pinch analyses were developed for several applications such as mass-exchange networks, water minimization, and material recycle. A very successful extension was "Hydrogen Pinch", which was applied to refinery hydrogen management. This allowed refiners to minimise the capital and operating costs of hydrogen supply to meet ever stricter environmental regulations and also increase hydrotreater yields.

Pinch analysis is a methodology for minimising energy consumption of chemical processes by calculating thermodynamically feasible energy targets and achieving them by optimising heat recovery systems, energy supply methods and process operating conditions. It is also known as process integration, heat integration, energy integration or pinch technology.

Water pinch analysis (WPA) originates from the concept of heat pinch analysis. WPA is a systematic technique for reducing water consumption and wastewater generation through integration of water-using activities or processes. WPA was first introduced by Wang and Smith. Since then, it has been widely used as a tool for water conservation in industrial process plants. Water Pinch Analysis has recently been applied for urban/domestic buildings. It was extended in 1998 by Nick Hallale at the University of Cape Town, who developed it as a special case of mass exchange networks for capital cost targeting.

An air separation plant separates atmospheric air into its primary components, typically nitrogen and oxygen, and sometimes also argon and other rare inert gases.

Petrolsoft Corporation (1989–2000) was a supply chain management software company with a focus on the petroleum industry. Petrolsoft Corporation was founded at Stanford University in 1989 by Bill Miller and David Gamboa as Petrolsoft Software Group. It was later incorporated in 1992. Petrolsoft introduced demand-driven inventory management to the petroleum industry.

Wealth Lab is a technical analysis software as well as an electronic trading platform owned by Fidelity Investments. It was created by Dion Kurczek, who founded the original Wealth-Lab, Inc. corporation in 2000. Fidelity acquired the Wealth-Lab software assets in 2004. The client runs on Microsoft Windows .NET Framework v4.0 and requires internet access to function properly. Licensed users can program and backtest trading strategies for stocks and futures. Fidelity premium account holders can use the platform to place trades produced by their trading strategies directly to their brokerage accounts and even setup auto-trading systems.

The service-oriented computing environment (SORCER) is a distributed computing platform implemented in Java. It allows writing network-programs that operate on wrapped applications (services) to spread across the network. SORCER is often utilized in scenarios similar to those where grids are used in order to run parallel tasks.

Aspen Plus, Aspen HYSYS, ChemCad and MATLAB, PRO are the commonly used process simulators for modeling, simulation and optimization of a distillation process in the chemical industries. Distillation is the technique of preferential separation of the more volatile components from the less volatile ones in a feed followed by condensation. The vapor produced is richer in the more volatile components. The distribution of the component in the two phase is governed by the vapour-liquid equilibrium relationship. In practice, distillation may be carried out by either two principal methods. The first method is based on the production of vapor boiling the liquid mixture to be separated and condensing the vapors without allowing any liquid to return to the still. There is no reflux. The second method is based on the return of part of the condensate to still under such conditions that this returning liquid is brought into intimate contact with the vapors on their way to condenser.

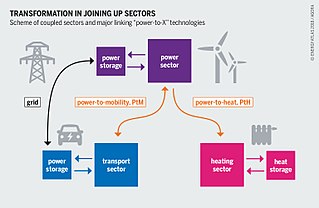

Power-to-X is a number of electricity conversion, energy storage, and reconversion pathways that use surplus electric power, typically during periods where fluctuating renewable energy generation exceeds load. Power-to-X conversion technologies allow for the decoupling of power from the electricity sector for use in other sectors, possibly using power that has been provided by additional investments in generation. The term is widely used in Germany and may have originated there.

Aspen HYSYS is a chemical process simulator currently developed by AspenTech used to mathematically model chemical processes, from unit operations to full chemical plants and refineries. HYSYS is able to perform many of the core calculations of chemical engineering, including those concerned with mass balance, energy balance, vapor-liquid equilibrium, heat transfer, mass transfer, chemical kinetics, fractionation, and pressure drop. HYSYS is used extensively in industry and academia for steady-state and dynamic simulation, process design, performance modelling, and optimization.

References

- Citations

- ↑ "Hydrogen optimization at minimal investment" (PDF). Archived from the original (PDF) on 2011-07-16. Retrieved 2009-11-05.

- ↑ "Pinch Analysis-" (PDF). Archived from the original (PDF) on 2011-09-30. Retrieved 2009-11-05.

- ↑ REFOPT Archived 2008-12-25 at the Wayback Machine

- ↑ Multi-period hydrogen management Archived 2011-07-22 at the Wayback Machine

- Sources

Nick Hallale, Ian Moore, Dennis Vauk, "Hydrogen optimization at minimal investment", Petroleum Technology Quarterly (PTQ), Spring (2003)