A safety data sheet (SDS), material safety data sheet (MSDS), or product safety data sheet (PSDS) is a document that lists information relating to occupational safety and health for the use of various substances and products. SDSs are a widely used system for cataloguing information on chemicals, chemical compounds, and chemical mixtures. SDS information may include instructions for the safe use and potential hazards associated with a particular material or product, along with spill-handling procedures. The older MSDS formats could vary from source to source within a country depending on national requirements; however, the newer SDS format is internationally standardized.

Occupational hygiene is the anticipation, recognition, evaluation, control, and confirmation of protection from hazards at work that may result in injury, illness, or affect the well being of workers. These hazards or stressors are typically divided into the categories biological, chemical, physical, ergonomic and psychosocial. The risk of a health effect from a given stressor is a function of the hazard multiplied by the exposure to the individual or group. For chemicals, the hazard can be understood by the dose response profile most often based on toxicological studies or models. Occupational hygienists work closely with toxicologists for understanding chemical hazards, physicists for physical hazards, and physicians and microbiologists for biological hazards Environmental and occupational hygienists are considered experts in exposure science and exposure risk management. Depending on an individual's type of job, a hygienist will apply their exposure science expertise for the protection of workers, consumers and/or communities.

Dangerous goods, abbreviated DG, are substances that when transported are a risk to health, safety, property or the environment. Certain dangerous goods that pose risks even when not being transported are known as hazardous materials.

Risk and Safety Statements, also known as R/S statements, R/S numbers, R/S phrases, and R/S sentences, is a system of hazard codes and phrases for labeling dangerous chemicals and compounds. The R/S statement of a compound consists of a risk part (R) and a safety part (S), each followed by a combination of numbers. Each number corresponds to a phrase. The phrase corresponding to the letter/number combination has the same meaning in different languages—see 'languages' in the menu on the left.

A chemical disaster is the unintentional release of one or more chemical hazard substances which could harm human health and the environment. Such events include fires, explosions, leakages or release of toxic or hazardous materials that can cause people illness, injury, or disability.

The Workplace Hazardous Materials Information System is Canada's national workplace hazard communication standard. The key elements of the system, which came into effect on October 31, 1988, are cautionary labelling of containers of WHMIS controlled products, the provision of material safety data sheets (MSDSs) and worker education and site-specific training programs.

The Globally Harmonized System of Classification and Labelling of Chemicals (GHS) is an internationally agreed-upon standard managed by the United Nations that was set up to replace the assortment of hazardous material classification and labelling schemes previously used around the world. Core elements of the GHS include standardized hazard testing criteria, universal warning pictograms, and harmonized safety data sheets which provide users of dangerous goods with a host of information. The system acts as a complement to the UN Numbered system of regulated hazardous material transport. Implementation is managed through the UN Secretariat. Although adoption has taken time, as of 2017, the system has been enacted to significant extents in most major countries of the world. This includes the European Union, which has implemented the United Nations' GHS into EU law as the CLP Regulation, and United States Occupational Safety and Health Administration standards.

Chemicals Convention, 1990 is an International Labour Organization Convention.

The Hazardous Materials Identification System (HMIS) is a numerical hazard rating that incorporates the use of labels with color developed by the American Coatings Association as a compliance aid for the OSHA Hazard Communication (HazCom) Standard.

The Canadian Centre for Occupational Health and Safety (CCOHS) is an independent departmental corporation under Schedule II of the Financial Administration Act and is accountable to Parliament through the Minister of Labour.

"Right to know" empowers "people by allowing them to participate in an informed way in decisions that affect them, while also holding governments and others accountable". It pursues universal access to information as essential foundations of inclusive knowledge societies.

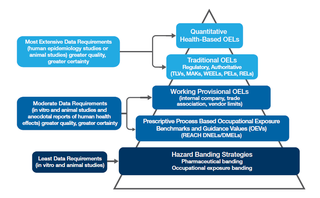

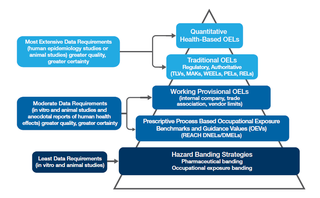

An occupational exposure limit is an upper limit on the acceptable concentration of a hazardous substance in workplace air for a particular material or class of materials. It is typically set by competent national authorities and enforced by legislation to protect occupational safety and health. It is an important tool in risk assessment and in the management of activities involving handling of dangerous substances. There are many dangerous substances for which there are no formal occupational exposure limits. In these cases, hazard banding or control banding strategies can be used to ensure safe handling.

Workplace health surveillance or occupational health surveillance (U.S.) is the ongoing systematic collection, analysis, and dissemination of exposure and health data on groups of workers. The Joint ILO/WHO Committee on Occupational Health at its 12th Session in 1995 defined an occupational health surveillance system as “a system which includes a functional capacity for data collection, analysis and dissemination linked to occupational health programmes”.

Chloroacetone is a chemical compound with the formula CH3COCH2Cl. At STP it is a colourless liquid with a pungent odour. On exposure to light, it turns to a dark yellow-amber colour. It was used as a tear gas in World War I.

Hazard statements form part of the Globally Harmonized System of Classification and Labelling of Chemicals (GHS). They are intended to form a set of standardized phrases about the hazards of chemical substances and mixtures that can be translated into different languages. As such, they serve the same purpose as the well-known R-phrases, which they are intended to replace.

European hazard symbols for chemicals are pictograms defined by the European Union for labelling chemical packaging and containers. They are standardised currently by the CLP/GHS classification.

The Hazard Communication Standard requires employers in the United States to disclose toxic and hazardous substances in workplaces. This is related to the Worker Protection Standard.

Occupational safety and health (OSH), also commonly referred to as occupational health and safety (OHS), occupational health, or occupational safety, is a multidisciplinary field concerned with the safety, health, and welfare of people at occupation. These terms also refer to the goals of this field, so their use in the sense of this article was originally an abbreviation of occupational safety and health program/department etc.

Chemical storage is the storage of controlled substances or hazardous materials in chemical stores, chemical storage cabinets, or similar devices.

Occupational exposure banding, also known as hazard banding, is a process intended to quickly and accurately assign chemicals into specific categories (bands), each corresponding to a range of exposure concentrations designed to protect worker health. These bands are assigned based on a chemical’s toxicological potency and the adverse health effects associated with exposure to the chemical. The output of this process is an occupational exposure band (OEB). Occupational exposure banding has been used by the pharmaceutical sector and by some major chemical companies over the past several decades to establish exposure control limits or ranges for new or existing chemicals that do not have formal OELs. Furthermore, occupational exposure banding has become an important component of the Hierarchy of Occupational Exposure Limits (OELs).