A nuclear reactor, formerly known as an atomic pile, is a device used to initiate and control a self-sustained nuclear chain reaction. Nuclear reactors are used at nuclear power plants for electricity generation and in nuclear marine propulsion. Heat from nuclear fission is passed to a working fluid, which in turn runs through steam turbines. These either drive a ship's propellers or turn electrical generators' shafts. Nuclear generated steam in principle can be used for industrial process heat or for district heating. Some reactors are used to produce isotopes for medical and industrial use, or for production of weapons-grade plutonium. As of early 2019, the IAEA reports there are 454 nuclear power reactors and 226 nuclear research reactors in operation around the world.

United States naval reactors are nuclear reactors used by the United States Navy aboard certain ships to generate the steam used to produce power for propulsion, electric power, catapulting airplanes in aircraft carriers, and a few more minor uses. Such naval nuclear reactors have a complete power plant associated with them. All U.S. Navy submarines and supercarriers built since 1975 are nuclear-powered by such reactors. There are no commissioned conventional (non-nuclear) submarines or aircraft carriers left in the U.S. Navy, since the last conventional carrier, USS Kitty Hawk, was decommissioned in May 2009. The U.S. Navy had nine nuclear-powered cruisers with such reactors also, but they have since been decommissioned. Reactors are designed by a variety of contractors, then developed and tested at one of several government -owned and prime contractor-operated facilities: Bettis Atomic Power Laboratory in West Mifflin, Pennsylvania and its associated Naval Reactors Facility in Idaho, and Knolls Atomic Power Laboratory in Niskayuna, New York and its associated Kesselring site in West Milton, New York, all under the management of the office of Naval Reactors. Sometimes there were full-scale nuclear-powered prototype plants built at the Naval Reactors Facility, Kesselring, and Windsor to test the nuclear plants, which were operated for years to train nuclear-qualified sailors.

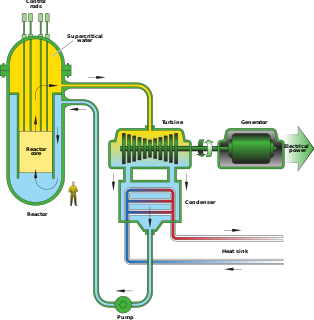

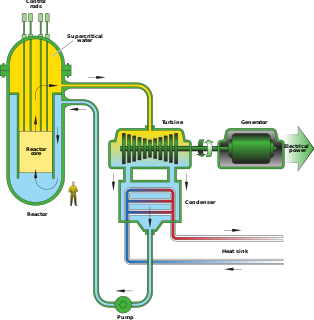

Pressurized water reactors (PWRs) constitute the large majority of the world's nuclear power plants and are one of three types of light-water reactor (LWR), the other types being boiling water reactors (BWRs) and supercritical water reactors (SCWRs). In a PWR, the primary coolant (water) is pumped under high pressure to the reactor core where it is heated by the energy released by the fission of atoms. The heated water then flows to a steam generator where it transfers its thermal energy to a secondary system where steam is generated and flows to turbines which, in turn, spin an electric generator. In contrast to a boiling water reactor, pressure in the primary coolant loop prevents the water from boiling within the reactor. All LWRs use ordinary water as both coolant and neutron moderator.

A boiling water reactor (BWR) is a type of light water nuclear reactor used for the generation of electrical power. It is the second most common type of electricity-generating nuclear reactor after the pressurized water reactor (PWR), which is also a type of light water nuclear reactor. The main difference between a BWR and PWR is that in a BWR, the reactor core heats water, which turns to steam and then drives a steam turbine. In a PWR, the reactor core heats water, which does not boil. This hot water then exchanges heat with a lower pressure water system, which turns to steam and drives the turbine. The BWR was developed by the Argonne National Laboratory and General Electric (GE) in the mid-1950s. The main present manufacturer is GE Hitachi Nuclear Energy, which specializes in the design and construction of this type of reactor.

A nuclear meltdown is a severe nuclear reactor accident that results in core damage from overheating. The term nuclear meltdown is not officially defined by the International Atomic Energy Agency or by the Nuclear Regulatory Commission. It has been defined to mean the accidental melting of the core of a nuclear reactor, however, and is in common usage a reference to the core's either complete or partial collapse.

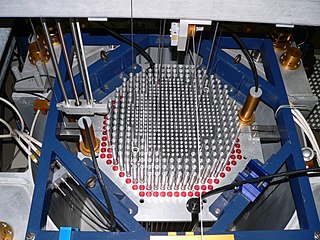

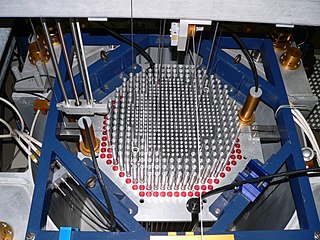

The RBMK is a class of graphite-moderated nuclear power reactor designed and built by the Soviet Union. The name refers to its unusual design where, instead of a large steel pressure vessel surrounding the entire core, each fuel assembly is enclosed in an individual 8 cm diameter pipe which allows the flow of cooling water around the fuel.

The A2W reactor is a naval nuclear reactor used by the United States Navy to provide electricity generation and propulsion on warships. The A2W designation stands for:

The light-water reactor (LWR) is a type of thermal-neutron reactor that uses normal water, as opposed to heavy water, as both its coolant and neutron moderator – furthermore a solid form of fissile elements is used as fuel. Thermal-neutron reactors are the most common type of nuclear reactor, and light-water reactors are the most common type of thermal-neutron reactor.

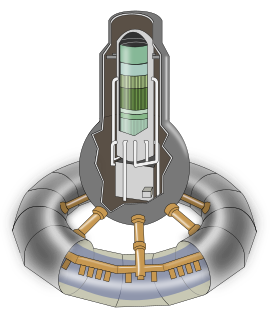

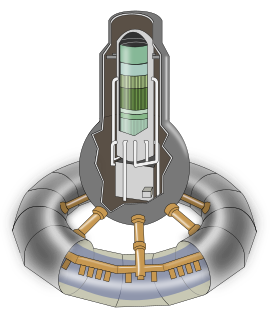

Passive nuclear safety is a design approach for safety features, implemented in a nuclear reactor, that does not require any active intervention on the part of the operator or electrical/electronic feedback in order to bring the reactor to a safe shutdown state, in the event of a particular type of emergency. Such design features tend to rely on the engineering of components such that their predicted behaviour would slow down, rather than accelerate the deterioration of the reactor state; they typically take advantage of natural forces or phenomena such as gravity, buoyancy, pressure differences, conduction or natural heat convection to accomplish safety functions without requiring an active power source. Many older common reactor designs use passive safety systems to a limited extent, rather, relying on active safety systems such as diesel powered motors. Some newer reactor designs feature more passive systems; the motivation being that they are highly reliable and reduce the cost associated with the installation and maintenance of systems that would otherwise require multiple trains of equipment and redundant safety class power supplies in order the achieve the same level of reliability. However, weak driving forces that power many passive safety features can pose significant challenges to effectiveness of a passive system, particularly in the short term following an accident.

A containment building, in its most common usage, is a reinforced steel or lead structure enclosing a nuclear reactor. It is designed, in any emergency, to contain the escape of radioactive steam or gas to a maximum pressure in the range of 275 to 550 kPa. The containment is the fourth and final barrier to radioactive release, the first being the fuel ceramic itself, the second being the metal fuel cladding tubes, the third being the reactor vessel and coolant system.

The supercritical water reactor (SCWR) is a concept Generation IV reactor, mostly designed as light water reactor (LWR) that operates at supercritical pressure. The term critical in this context refers to the critical point of water, and must not be confused with the concept of criticality of the nuclear reactor.

Steam generators are heat exchangers used to convert water into steam from heat produced in a nuclear reactor core. They are used in pressurized water reactors (PWR) between the primary and secondary coolant loops.

The water-water energetic reactor (WWER), or VVER is a series of pressurized water reactor designs originally developed in the Soviet Union, and now Russia, by OKB Gidropress. The idea of a reactor was proposed at the Kurchatov Institute by Savely Moiseevich Feinberg. VVER were originally developed before the 1970s, and have been continually updated. As a result, the name VVER is associated with a wide variety of reactor designs spanning from generation I reactors to modern generation III+ reactor designs. Power output ranges from 70 to 1300 MWe, with designs of up to 1700 MWe in development. The first prototype VVER-210 was built at the Novovoronezh Nuclear Power Plant.

A reactor protection system (RPS) is a set of nuclear safety and security components in a nuclear power plant designed to safely shut down the reactor and prevent the release of radioactive materials. The system can "trip" automatically, or it can be tripped by the operators. Trips occurs when the parameters meet or exceed the limit setpoint. A trip of the RPS results in full insertion of all control rods and shutdown of the reactor.

The three primary objectives of nuclear reactor safety systems as defined by the U.S. Nuclear Regulatory Commission are to shut down the reactor, maintain it in a shutdown condition and prevent the release of radioactive material.

A nuclear reactor coolant is a coolant in a nuclear reactor used to remove heat from the nuclear reactor core and transfer it to electrical generators and the environment. Frequently, a chain of two coolant loops are used because the primary coolant loop takes on short-term radioactivity from the reactor.

General Electric's BWR product line of Boiling Water Reactors represents the designs of a relatively large percentage of the commercial fission reactors around the world.

The APR-1400 is an advanced pressurized water nuclear reactor designed by the Korea Electric Power Corporation (KEPCO). Originally known as the Korean Next Generation Reactor (KNGR), this Generation III reactor was developed from the earlier OPR-1000 design and also incorporates features from the US Combustion Engineering (C-E) System 80+ design. Currently there is one unit in operation and seven units under construction, four in the United Arab Emirates at Barakah and three in South Korea: one at Shin Kori and two at Shin Hanul. Two more units are planned with construction yet to commence at Shin Kori.

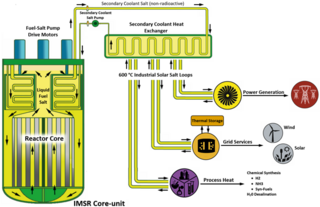

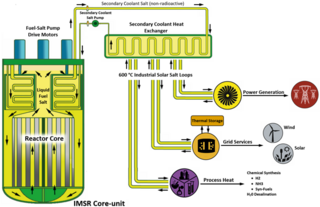

The Integral Molten Salt Reactor (IMSR) is designed for the small modular reactor (SMR) market. It employs molten salt reactor technology which is being developed by the Canadian company Terrestrial Energy. It is based closely on the denatured molten salt reactor (DMSR), a reactor design from Oak Ridge National Laboratory. It also incorporates elements found in the SmAHTR, a later design from the same laboratory. The IMSR belongs to the DMSR class of molten salt reactors (MSR) and hence is a "burner" reactor that employs a liquid fuel rather than a conventional solid fuel; this liquid contains the nuclear fuel and also serves as primary coolant.