Cast iron is a class of iron–carbon alloys with a carbon content of more than 2% and silicon content around 1–3%. Its usefulness derives from its relatively low melting temperature. The alloying elements determine the form in which its carbon appears: white cast iron has its carbon combined into an iron carbide named cementite, which is very hard, but brittle, as it allows cracks to pass straight through; grey cast iron has graphite flakes which deflect a passing crack and initiate countless new cracks as the material breaks, and ductile cast iron has spherical graphite "nodules" which stop the crack from further progressing.

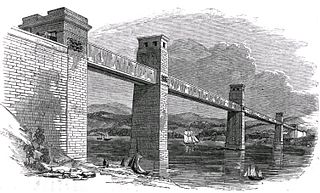

The Tay Bridge carries rail traffic across the Firth of Tay in Scotland between Dundee and the suburb of Wormit in Fife. Its span is 2.75 miles. It is the second bridge to occupy the site.

A truss bridge is a bridge whose load-bearing superstructure is composed of a truss, a structure of connected elements, usually forming triangular units. The connected elements, typically straight, may be stressed from tension, compression, or sometimes both in response to dynamic loads. There are several types of truss bridges, including some with simple designs that were among the first bridges designed in the 19th and early 20th centuries. A truss bridge is economical to construct primarily because it uses materials efficiently.

A trestle bridge is a bridge composed of a number of short spans supported by closely spaced frames. A trestle is a rigid frame used as a support, historically a tripod used to support a stool or a pair of isosceles triangles joined at their apices by a plank or beam such as the support structure for a trestle table. Each supporting frame is a bent. A trestle differs from a viaduct in that viaducts have towers that support much longer spans and typically have a higher elevation.

Steel frame is a building technique with a "skeleton frame" of vertical steel columns and horizontal I-beams, constructed in a rectangular grid to support the floors, roof and walls of a building which are all attached to the frame. The development of this technique made the construction of the skyscraper possible. Steel frame has displaced its predecessor, the iron frame, in the early 20th century.

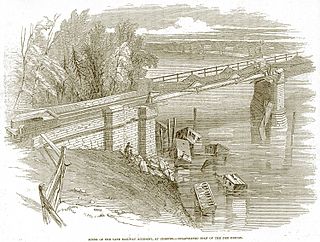

The Dee Bridge disaster was a rail accident that occurred on 24 May 1847 in Chester, England, that resulted in five fatalities. It revealed the weakness of cast iron beam bridges reinforced by wrought iron tie bars, and brought criticism of its designer, Robert Stephenson, the son of George Stephenson.

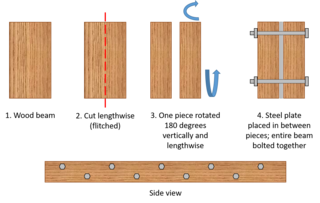

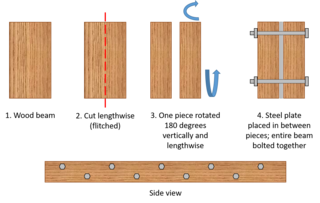

A flitch beam is a compound beam used in the construction of houses, decks, and other primarily wood-frame structures. Typically, the flitch beam is made up of a vertical steel plate sandwiched between two wood beams, the three layers being held together with bolts. In that common form it is sometimes referenced as a steel flitch beam. Further alternating layers of wood and steel can be used to produce an even stronger beam. The metal plates within the beam are known as flitch plates.[1] Flitch beams were used as a cost-effective way to strengthen long-span wooden beams, and have been largely supplanted by more recent technology.

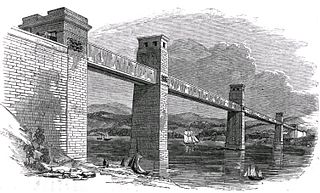

The Tay Bridge disaster occurred during a violent storm on Sunday 28 December 1879, when the first Tay Rail Bridge collapsed as a North British Railway (NBR) passenger train on the Edinburgh to Aberdeen Line from Burntisland bound for its final destination of Dundee passed over it, killing everybody on board. The bridge—designed by Sir Thomas Bouch—used lattice girders supported by iron piers, with cast iron columns and wrought iron cross-bracing. The piers were narrower and their cross-bracing was less extensive and robust than on previous similar designs by Bouch.

A girder bridge is a bridge that uses girders as the means of supporting its deck. The two most common types of modern steel girder bridges are plate and box.

A box girder or tubular girder is a girder that forms an enclosed tube with multiple walls, as opposed to an I- or H-beam. Originally constructed of wrought iron joined by riveting, they are now made of rolled or welded steel, aluminium extrusions or prestressed concrete.

A steel building is a metal structure fabricated with steel for the internal support and for exterior cladding, as opposed to steel framed buildings which generally use other materials for floors, walls, and external envelope. Steel buildings are used for a variety of purposes including storage, work spaces and living accommodation. They are classified into specific types depending on how they are used.

Cast-iron architecture is the use of cast iron in buildings and objects, ranging from bridges and markets to warehouses, balconies and fences. Refinements developed during the Industrial Revolution in the late 18th century made cast iron relatively cheap and suitable for a range of uses, and by the mid-19th century it was common as a structural material, and particularly for elaborately patterned architectural elements such as fences and balconies, until it fell out of fashion after 1900 as a decorative material, and was replaced by modern steel and concrete for structural purposes.

A Howe truss is a truss bridge consisting of chords, verticals, and diagonals whose vertical members are in tension and whose diagonal members are in compression. The Howe truss was invented by William Howe in 1840, and was widely used as a bridge in the mid to late 1800s.

Metals used for architectural purposes include lead, for water pipes, roofing, and windows; tin, formed into tinplate; zinc, copper and aluminium, in a range of applications including roofing and decoration; and iron, which has structural and other uses in the form of cast iron or wrought iron, or made into steel. Metal alloys used in building include bronze ; brass ; monel metal and nickel silver, mainly consisting of nickel and copper; and stainless steel, with important components of nickel and chromium.

An anchor plate, floor plate or wall washer is a large plate or washer connected to a tie rod or bolt. Anchor plates are used on exterior walls of masonry buildings, for structural reinforcement against lateral bowing. Anchor plates are made of cast iron, sometimes wrought iron or steel, and are often made in a decorative style.

The history of structural engineering dates back to at least 2700 BC when the step pyramid for Pharaoh Djoser was built by Imhotep, the first architect in history known by name. Pyramids were the most common major structures built by ancient civilizations because it is a structural form which is inherently stable and can be almost infinitely scaled.

The St Pancras Basin, also known as St Pancras Yacht Basin, is part of the Regent's Canal in the London Borough of Camden, England, slightly to the west of St Pancras Lock. Formerly known as the Midland Railway Basin,

An ironworker is a tradesman who works in the iron-working industry. Ironworkers assemble the structural framework in accordance with engineered drawings and install the metal support pieces for new buildings. They also repair and renovate old structures using reinforced concrete and steel. Ironworkers may work on factories, steel mills, and utility plants.

Domes built in the 19th, 20th, and 21st centuries benefited from more efficient techniques for producing iron and steel as well as advances in structural analysis.

The Ultimo Road railway underbridge is a heritage-listed former railway bridge located on the former Darling Harbour goods railway line in the inner city Sydney suburb of Ultimo in the City of Sydney local government area of New South Wales, Australia. It was designed by engineering staff in the Existing Lines branch of the New South Wales Public Works Department and built in 1879. The property is owned by Transport Asset Holding Entity, an agency of the Government of New South Wales. It was added to the New South Wales State Heritage Register on 2 April 1999.