Sewage sludge is the residual, semi-solid material that is produced as a by-product during sewage treatment of industrial or municipal wastewater. The term "septage" also refers to sludge from simple wastewater treatment but is connected to simple on-site sanitation systems, such as septic tanks.

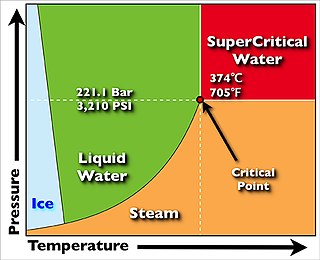

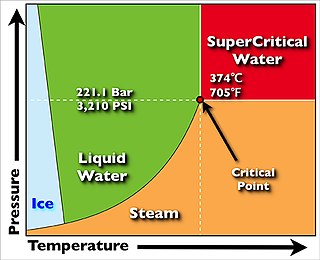

Supercritical water oxidation (SCWO) is a process that occurs in water at temperatures and pressures above a mixture's thermodynamic critical point. Under these conditions water becomes a fluid with unique properties that can be used to advantage in the destruction of recalcitrant and hazardous wastes such as polychlorinated biphenyls (PCB) or Per- and polyfluoroalkyl substances (PFASs). Supercritical water has a density between that of water vapor and liquid at standard conditions, and exhibits high gas-like diffusion rates along with high liquid-like collision rates. In addition, the behavior of water as a solvent is altered - it behaves much less like a polar solvent. As a result, the solubility behavior is "reversed" so that oxygen, and organics such as chlorinated hydrocarbons become soluble in the water, allowing single-phase reaction of aqueous waste with a dissolved oxidizer. The reversed solubility also causes salts to precipitate out of solution, meaning they can be treated using conventional methods for solid-waste residuals. Efficient oxidation reactions occur at low temperature with reduced NOx production.

Wastewater treatment is a process used to remove contaminants from wastewater and convert it into an effluent that can be returned to the water cycle. Once returned to the water cycle, the effluent creates an acceptable impact on the environment or is reused for various purposes. The treatment process takes place in a wastewater treatment plant. There are several kinds of wastewater which are treated at the appropriate type of wastewater treatment plant. For domestic wastewater, the treatment plant is called a sewage treatment plant. For industrial wastewater, treatment either takes place in a separate industrial wastewater treatment plant, or in a sewage treatment plant. Further types of wastewater treatment plants include agricultural wastewater treatment plants and leachate treatment plants.

A bioreactor refers to any manufactured device or system that supports a biologically active environment. In one case, a bioreactor is a vessel in which a chemical process is carried out which involves organisms or biochemically active substances derived from such organisms. This process can either be aerobic or anaerobic. These bioreactors are commonly cylindrical, ranging in size from litres to cubic metres, and are often made of stainless steel. It may also refer to a device or system designed to grow cells or tissues in the context of cell culture. These devices are being developed for use in tissue engineering or biochemical/bioprocess engineering.

Biosolids are solid organic matter recovered from a sewage treatment process and used as fertilizer. In the past, it was common for farmers to use animal manure to improve their soil fertility. In the 1920s, the farming community began also to use sewage sludge from local wastewater treatment plants. Scientific research over many years has confirmed that these biosolids contain similar nutrients to those in animal manures. Biosolids that are used as fertilizer in farming are usually treated to help to prevent disease-causing pathogens from spreading to the public. Some sewage sludge can not qualify as biosolids due to persistent, bioaccumulative and toxic chemicals, radionuclides, and heavy metals at levels sufficient to contaminate soil and water when applied to land.

Waste stabilization ponds are ponds designed and built for wastewater treatment to reduce the organic content and remove pathogens from wastewater. They are man-made depressions confined by earthen structures. Wastewater or "influent" enters on one side of the waste stabilization pond and exits on the other side as "effluent", after spending several days in the pond, during which treatment processes take place.

The activated sludge process is a type of wastewater treatment process for treating sewage or industrial wastewaters using aeration and a biological floc composed of bacteria and protozoa.

Anaerobic digestion is a sequence of processes by which microorganisms break down biodegradable material in the absence of oxygen. The process is used for industrial or domestic purposes to manage waste or to produce fuels. Much of the fermentation used industrially to produce food and drink products, as well as home fermentation, uses anaerobic digestion.

An aerated lagoon is a simple wastewater treatment system consisting of a pond with artificial aeration to promote the biological oxidation of wastewaters.

Secondary treatment is the removal of biodegradable organic matter from sewage or similar kinds of wastewater. The aim is to achieve a certain degree of effluent quality in a sewage treatment plant suitable for the intended disposal or reuse option. A "primary treatment" step often precedes secondary treatment, whereby physical phase separation is used to remove settleable solids. During secondary treatment, biological processes are used to remove dissolved and suspended organic matter measured as biochemical oxygen demand (BOD). These processes are performed by microorganisms in a managed aerobic or anaerobic process depending on the treatment technology. Bacteria and protozoa consume biodegradable soluble organic contaminants while reproducing to form cells of biological solids. Secondary treatment is widely used in sewage treatment and is also applicable to many agricultural and industrial wastewaters.

Sequencing batch reactors (SBR) or sequential batch reactors are a type of activated sludge process for the treatment of wastewater. SBR reactors treat wastewater such as sewage or output from anaerobic digesters or mechanical biological treatment facilities in batches. Oxygen is bubbled through the mixture of wastewater and activated sludge to reduce the organic matter. The treated effluent may be suitable for discharge to surface waters or possibly for use on land.

Sewage sludge treatment describes the processes used to manage and dispose of sewage sludge produced during sewage treatment. Sludge treatment is focused on reducing sludge weight and volume to reduce transportation and disposal costs, and on reducing potential health risks of disposal options. Water removal is the primary means of weight and volume reduction, while pathogen destruction is frequently accomplished through heating during thermophilic digestion, composting, or incineration. The choice of a sludge treatment method depends on the volume of sludge generated, and comparison of treatment costs required for available disposal options. Air-drying and composting may be attractive to rural communities, while limited land availability may make aerobic digestion and mechanical dewatering preferable for cities, and economies of scale may encourage energy recovery alternatives in metropolitan areas.

Fine bubble diffusers are a pollution control technology used to aerate wastewater for sewage treatment.

Aerobic digestion is a process in sewage treatment designed to reduce the volume of sewage sludge and make it suitable for subsequent use. More recently, technology has been developed that allows the treatment and reduction of other organic waste, such as food, cardboard and horticultural waste. It is a bacterial process occurring in the presence of oxygen. Bacteria rapidly consume organic matter and convert it into carbon dioxide, water and a range of lower molecular weight organic compounds. As there is no new supply of organic material from sewage, the activated sludge biota begin to die and are used as food by saprotrophic bacteria. This stage of the process is known as endogenous respiration and it is process that reduces the solid concentration in the sludge.

A trickling filter is a type of wastewater treatment system. It consists of a fixed bed of rocks, coke, gravel, slag, polyurethane foam, sphagnum peat moss, ceramic, or plastic media over which sewage or other wastewater flows downward and causes a layer of microbial slime (biofilm) to grow, covering the bed of media. Aerobic conditions are maintained by splashing, diffusion, and either by forced-air flowing through the bed or natural convection of air if the filter medium is porous. The treatment of sewage or other wastewater with trickling filters is among the oldest and most well characterized treatment technologies.

Sewage treatment is a type of wastewater treatment which aims to remove contaminants from sewage to produce an effluent that is suitable for discharge to the surrounding environment or an intended reuse application, thereby preventing water pollution from raw sewage discharges. Sewage contains wastewater from households and businesses and possibly pre-treated industrial wastewater. There are a high number of sewage treatment processes to choose from. These can range from decentralized systems to large centralized systems involving a network of pipes and pump stations which convey the sewage to a treatment plant. For cities that have a combined sewer, the sewers will also carry urban runoff (stormwater) to the sewage treatment plant. Sewage treatment often involves two main stages, called primary and secondary treatment, while advanced treatment also incorporates a tertiary treatment stage with polishing processes and nutrient removal. Secondary treatment can reduce organic matter from sewage, using aerobic or anaerobic biological processes.

Membrane bioreactor (MBR) is a combination of membrane process like microfiltration or ultrafiltration with a biological wastewater treatment process, the activated sludge process. It is now widely used for municipal and industrial wastewater treatment. There are two different types, internal meaning that the membranes are inside the biological reactor, and the external, meaning that the membranes are separate and require an additional step.

Facultative lagoons are a type of waste stabilization pond used for biological treatment of industrial and domestic wastewater. Sewage or organic waste from food or fiber processing may be catabolized in a system of constructed ponds where adequate space is available to provide an average waste retention time exceeding a month. A series of ponds prevents mixing of untreated waste with treated wastewater and allows better control of waste residence time for uniform treatment efficiency.

Mogden Sewage Treatment Works is a sewage treatment plant in the Ivybridge section of Isleworth, West London, formerly known as Mogden. Built in 1931–36 by Middlesex County Council and now operated by Thames Water, it is the third largest sewage works in the United Kingdom. It treats the waste water from about 1.9 million people served by three sewers in North and West London. The plant has been extended to its geographical boundaries and is constantly being upgraded with new process, most recently in OfWat Amp6 by the Costain Atkins Joint venture who delivered 6MW of Combined Heat and Power (CHP) generation, New process air blowers for Batterys A&B and 6 new gravity sludge thickening streams. The site now covers 55 hectares.