A power loom is a mechanized loom, and was one of the key developments in the industrialization of weaving during the early Industrial Revolution. The first power loom was designed in 1784 by Edmund Cartwright and first built in 1785. It was refined over the next 47 years until a design by Kenworthy and Bullough made the operation completely automatic.

Mather & Platt is the name of several large engineering firms in Europe, South Africa and Asia that are subsidiaries of Wilo SE, Germany or were founded by former employees. The original company was founded in the Newton Heath area of Manchester, England, where it was a major employer. That firm continues as a food processing and packaging business, trading as M & P Engineering in Trafford Park, Manchester.

The Lancashire Loom was a semi-automatic power loom invented by James Bullough and William Kenworthy in 1842. Although it is self-acting, it has to be stopped to recharge empty shuttles. It was the mainstay of the Lancashire cotton industry for a century.

Tweedales and Smalley was a manufacturer of textile machinery in Castleton, Rochdale, Greater Manchester, in England. It specialised in ring spinning frames mainly for export.

John Hetherington & Sons was a textile machinery manufacturer from Ancoats, Manchester in England, founded in 1830

In the recession of the 1930s, Platt Brothers, Howard and Bullough, Brooks and Doxey, Asa Lees, Dobson and Barlow, Joseph Hibbert, John Hetherington and Tweedales and Smalley merged to become Textile Machinery Makers Ltd., but the individual units continued to trade under their own names until the 1970, when they were rationalised into one company called Platt UK Ltd. In 1991 the company name changed to Platt Saco Lowell. The Globe works closed in 1993.

Asa Lees was a firm of textile machine manufacturers in Oldham, Lancashire. Their headquarters was the Soho Iron Works, Greenacres. It was second only in size to Platt Brothers.

Dobson and Barlow were manufacturers of textile machinery with works in Bolton, Greater Manchester. Isaac Dobson (1767-1833) founded the company in 1790 and by 1850 Dobson in partnership with Peter Rothwell had premises in Blackhorse Street which produced mules for cotton spinning. The company moved to a larger factory in Kay Street which had 1,600 workers in 1860.

Butterworth and Dickinson were textile machinery manufacturers in Burnley, Lancashire, England. Known as Butts and Dicks the company made looms that were exported around the world.

Taylor, Lang & Co. was a textile machinery manufacturer based in Stalybridge, Greater Manchester, England.

May Mill, Pemberton is a cotton spinning mill in Pemberton, Wigan, Greater Manchester. Historically in Lancashire, it was built in 1889. It was taken over by the Lancashire Cotton Corporation in the 1930s and passed to Courtaulds in 1962–63 to produce carpet fibre, which it continued to do until its closure on 17 October 1980.

Geo. Hattersley was a textile machinery manufacturer from Keighley, West Yorkshire in England, founded in 1789 and responsible for the Hattersley Standard Loom and other types of looms.

Royd Mill, Oldham was a cotton spinning mill in Hollinwood, Oldham, Greater Manchester. It was built in 1907, and extended in 1912 and 1924. It was taken over by the Lancashire Cotton Corporation in the 1930s and passed to Courtaulds in 1964. Production finished in 1981. The mill was demolished in 2015 to make way for a "DifRent" housing scheme.

Queen Street Mill is a Grade I listed building. in Harle Syke, a suburb to the north-east of Burnley, Lancashire. It was built in 1894 for the Queen Street Manufacturing Company. It closed on 12 March 1982 and was mothballed, but was subsequently taken over by Burnley Borough Council and maintained as a museum. In the 1990s ownership passed to Lancashire Museums. Unique in being the world's only surviving operational steam-driven weaving shed, it received an Engineering Heritage Award in November 2010.

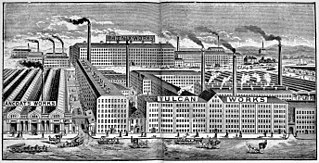

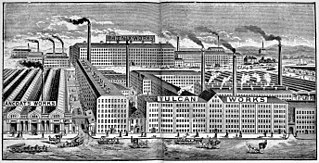

The Globe Works is a former industrial works in Accrington, Lancashire that following refurbishment contains rented offices and conference rooms and is known as the Globe Centre. The centre is made up of the remainder of The Globe Works, which created machinery and looms for the cotton industry under management of the Howard & Bullough firm.

The technique of sizing a warp was mechanised during the nineteenth century when William Radcliffe and his assistant Thomas Johnson invented the sizing machine. The purpose of introducing size, which is either a starchy substance for cotton or gelatinous mixture for woollen fibre, is to reduce the chances of threads fraying and breaking due to the friction of the weaving process. The size stiffens the thread and helps the fibres lie closely together. Many recipes for size can be found in textile manufacturing books. The recipes include flour, sago, china clay, types of soap, fats and some chemicals.

Bancroft Shed was a weaving shed in Barnoldswick, Lancashire, England, situated on the road to Skipton. Construction was started in 1914 and the shed was commissioned in 1920 for James Nutter & Sons Limited. The mill closed on 22 December 1978 and was demolished. The engine house, chimneys and boilers have been preserved and maintained as a working steam museum. The mill was the last steam-driven weaving shed to be constructed and the last to close.