Notes

- ↑ The typical accurate hygrometer of the day was the 'wet and dry bulb' psychrometer. This uses two thermometers, one with its bulb in open air and the other with it wrapped in a thin cloth, kept damp. The wet-bulb temperature is always lower, owing to evaporation of the water, and comparing the two readings against a chart gives a measure of the air's humidity.

Related Research Articles

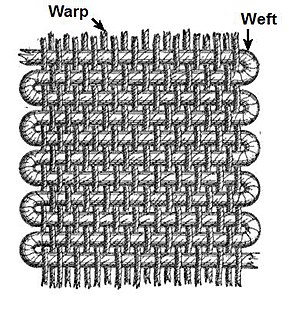

Weaving is a method of textile production in which two distinct sets of yarns or threads are interlaced at right angles to form a fabric or cloth. Other methods are knitting, crocheting, felting, and braiding or plaiting. The longitudinal threads are called the warp and the lateral threads are the weft, woof, or filling. The method in which these threads are inter-woven affects the characteristics of the cloth. Cloth is usually woven on a loom, a device that holds the warp threads in place while filling threads are woven through them. A fabric band which meets this definition of cloth can also be made using other methods, including tablet weaving, back strap loom, or other techniques without looms.

A power loom is a mechanized loom, and was one of the key developments in the industrialization of weaving during the early Industrial Revolution. The first power loom was designed in 1787 by Edmund Cartwright and first built in 1787. It was refined over the next 47 years until a design by Kenworthy and Bullough made the operation completely automatic.

A cotton mill is a building that houses spinning or weaving machinery for the production of yarn or cloth from cotton, an important product during the Industrial Revolution in the development of the factory system.

Textile manufacture during the Industrial Revolution in Britain was centred in south Lancashire and the towns on both sides of the Pennines. In Germany it was concentrated in the Wupper Valley, Ruhr Region and Upper Silesia, in Spain it was concentrated in Catalonia while in the United States it was in New England. The main key drivers of the Industrial Revolution were textile manufacturing, iron founding, steam power, oil drilling, the discovery of electricity and its many industrial applications, the telegraph and many others. Railroads, steam boats, the telegraph and other innovations massively increased worker productivity and raised standards of living by greatly reducing time spent during travel, transportation and communications.

The textile industry is primarily concerned with the design, production and distribution of yarn, cloth and clothing. The raw material may be natural, or synthetic using products of the chemical industry.

A weavers' cottage was a type of house used by weavers for cloth production in the putting-out system sometimes known as the domestic system.

Harp Mill was a former cotton spinning mill in the Castleton, Rochdale, Greater Manchester, England. Queensway, Castleton was a hub of cotton mills including the three 't', Th'Arrow, Th'Harp, and Th'Ensor. The 1908 Castleton map includes: Marland Cotton Mill, Castleton Cotton Mill, Globe Works, Arrow Cotton Mill, Harp Cotton Mill, Globe Leather Works, Castleton Size Works and Castleton Iron Works. Th'Harp was taken over by the Lancashire Cotton Corporation in the 1930s and passed to Courtaulds in 1964. The site now houses industrial units.

Queen Street Mill is a former weaving mill in Harle Syke, a suburb to the north-east of Burnley, Lancashire, that is a Grade I listed building. It was built in 1894 for the Queen Street Manufacturing Company. It closed on 12 March 1982 and was mothballed, but was subsequently taken over by Burnley Borough Council and maintained as a museum. In the 1990s ownership passed to Lancashire Museums. Unique in being the world's only surviving operational steam-driven weaving shed, it received an Engineering Heritage Award in November 2010.

The Amalgamated Weavers' Association, often known as the Weavers' Amalgamation, was a trade union in the United Kingdom. Initially, it operated in competition with the North East Lancashire Amalgamated Weavers' Association in part of its area, and it was therefore nicknamed the Second Amalgamation.

Bancroft Shed was a weaving shed in Barnoldswick, Lancashire, England, situated on the road to Skipton. Construction was started in 1914 and the shed was commissioned in 1920 for James Nutter & Sons Limited. The mill closed on 22 December 1978 and was demolished. The engine house, chimneys and boilers have been preserved and maintained as a working steam museum. The mill was the last steam-driven weaving shed to be constructed and the last to close.

The more looms system was a productivity strategy introduced in the Lancashire cotton industry, whereby each weaver would manage a greater number of looms. It was an alternative to investing in the more productive Northrop automatic looms in the 1930s. It caused resentment, industrial action and failed to achieve any significant cost savings.

"Kissing the shuttle" is the term for a process by which weavers used their mouths to pull thread through the eye of a shuttle when the pirn was replaced. The same shuttles were used by many weavers, and the practice was unpopular. It was outlawed in the U.S. state of Massachusetts in 1911 but continued even after it had been outlawed in Lancashire, England in 1952. The Lancashire cotton industry was loath to invest in hand-threaded shuttles, or in the more productive Northrop automatic looms with self-threading shuttles, which were introduced in 1902.

Piece-rate lists were the ways of assessing a cotton operatives pay in Lancashire in the nineteenth and early twentieth centuries. They started as informal agreements made by one cotton master and his operatives then each cotton town developed their own list. Spinners merged all of these into two main lists which were used by all, while weavers used one 'unified' list.

Harle Syke mill is a weaving shed in Briercliffe on the outskirts of Burnley, Lancashire. It was built on a green field site in 1856, together with terraced houses for the workers. These formed the nucleus of the community of Harle Syke. The village expanded and six other mills were built, including Queen Street Mill.

The United Textile Factory Workers' Association (UTFWA) was a trade union federation in Great Britain. It was active from 1889 until 1975.

Carey Hargreaves was a British trade unionist.

The North East Lancashire Amalgamated Weavers' Association was a trade union federation of local weavers' unions in part of Lancashire in England, in the 19th century.

The Northern Counties Textile Trades Federation was a trade union federation in northern England.

The Padiham and District Weavers', Winders' and Warpers' Association was a trade union representing cotton weavers in the Padiham area of Lancashire, in England.

References

- 1 2 3 Greenlees 2005.

- ↑ Farnie 1979, pp. 138–149.

- ↑ Fowler 2003, p. 149.

- ↑ Fowler 2003, p. 150.

- ↑ Hopwood 1969, p. 71.

- 1 2 Fowler 2003, p. 153.

- ↑ Hopwood 1969, pp. 71–2.

- ↑ Fowler 2003, p. 159.

- ↑ See Cotton Cloth Factories Act of 1911

- ↑ Hopwood 1969, p. 72.

Bibliography

- Farnie, D.A. (1979), The English Cotton Industry and the World Market 1815–1896, Clarendon Press, ISBN 0-19-822478-8

- Fowler, Alan (2003). Lancashire Cotton Operatives and Work,1900–1950: A social history of Lancashire cotton operatives in the twentieth century. Aldershot: Ashgate Publishing Ltd. ISBN 0-7546-01161.

- Greenlees, Janet (2005). "'Stop Kissing and Steaming!': Tuberculosis and the Occupational Health Movement in the Massachusetts and Lancashire Cotton Weaving Industries, 1870–1918". Urban History. 32 (2): 223–246. doi:10.1017/S0963926805002981. PMC 3087970 . PMID 21552481.

- Hopwood, Edwin (1969). A History of the Lancashire Cotton Industry and the Amalgamated Weavers' Association. Manchester: The Amalgamated Weavers' Association.