Lewis Paul (died 1759) was the original inventor of roller spinning, the basis of the water frame for spinning cotton in a cotton mill.

Lewis Paul (died 1759) was the original inventor of roller spinning, the basis of the water frame for spinning cotton in a cotton mill.

Lewis Paul was of Huguenot descent. His father was physician to Lord Shaftesbury. He may have begun work on designing a spinning machine for cotton as early as 1729, but probably did not make practical progress until after 1732 when he met John Wyatt, a carpenter then working in Birmingham for a gun barrel forger. Wyatt had designed a machine, probably for cutting files, in which Paul took an interest.

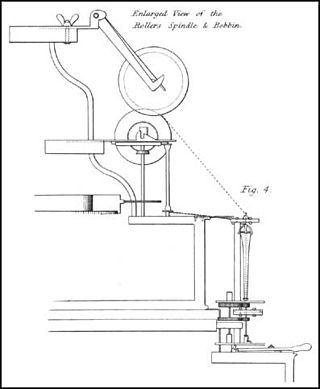

Roller spinning was certainly Paul's idea, and Wyatt built a machine (or model) for him. Paul obtained a patent for this on 24 June 1738. He then set about trying to license his machine, though some licences were granted in satisfaction of debts. In 1741, he set up a machine powered by two asses in the Upper Priory in Birmingham, near his house in Old Square.

Edward Cave, a publisher, obtained a licence and set up machines in a warehouse in London. In 1742, he acquired Marvel's Mill on the River Nene at Northampton. He rebuilt the mill to hold four or five water-powered spinning machines, each with 50 spindles. This was thus the first cotton mill. Cave died on 10 January 1754, so that the mill passed to his brother William and his nephew Paul. Samuel Touchet, a London merchant had the mill until 1755, but made no profit. It may then have been let to Lewis Paul, but he died in 1759. The Caves forfeited the lease for non-payment of rent in March 1761 and advertised the mill to let in November 1761. By 1768, the mill had reverted to being a corn mill.

Another mill that operated under Paul's patent was at Leominster. This was built in 1744 by John Bourn in partnership with Henry Morris of Lancashire. The mill burnt down in November 1754.

In 1748, Daniel Bourn and Lewis Paul separately obtained patents for carding machines, which were presumably used in the Leominster and Northampton mills respectively. This carding technology of Lewis Paul and Daniel Bourn seems to be the basis of later carding machines.

The principle of his rolling spinning process was perfected by John Kay and Thomas Highs and promoted by Richard Arkwright. [1] [2] Paul's machine seems only to have been modestly profitable, and it is not clear to what extent his work is reflected in Arkwright's much more successful machine, the water frame, patented in 1769. Like Paul and Bourn, Arkwright subsequently added a carding stage to his machinery, but his use of this as a means of continuing his patent rights beyond the expiry of his original patent failed, because the improvement was not his invention.

Carding is a mechanical process that disentangles, cleans and intermixes fibres to produce a continuous web or sliver suitable for subsequent processing. This is achieved by passing the fibres between differentially moving surfaces covered with "card clothing", a firm flexible material embedded with metal pins. It breaks up locks and unorganised clumps of fibre and then aligns the individual fibres to be parallel with each other. In preparing wool fibre for spinning, carding is the step that comes after teasing.

Sir Richard Arkwright was an English inventor and a leading entrepreneur during the early Industrial Revolution. He is credited as the driving force behind the development of the spinning frame, known as the water frame after it was adapted to use water power; and he patented a rotary carding engine to convert raw cotton to 'cotton lap' prior to spinning. He was the first to develop factories housing both mechanised carding and spinning operations.

Leominster is a market town in Herefordshire, England, at the confluence of the River Lugg and its tributary the River Kenwater. The town is 12 miles north of Hereford and seven miles south of Ludlow in Shropshire. With a population of 11,700, Leominster is the largest of the five towns in the county.

A cotton mill is a building that houses spinning or weaving machinery for the production of yarn or cloth from cotton, an important product during the Industrial Revolution in the development of the factory system.

Edward Cave was an English printer, editor and publisher. He coined the term "magazine" for a periodical, founding The Gentleman's Magazine in 1731, and was the first publisher to successfully fashion a wide-ranging publication.

Textile manufacture during the British Industrial Revolution was centred in south Lancashire and the towns on both sides of the Pennines in the United Kingdom. The main drivers of the Industrial Revolution were textile manufacturing, iron founding, steam power, oil drilling, the discovery of electricity and its many industrial applications, the telegraph and many others. Railroads, steam boats, the telegraph and other innovations massively increased worker productivity and raised standards of living by greatly reducing time spent during travel, transportation and communications..

The spinning frame is an Industrial Revolution invention for spinning thread or yarn from fibres such as wool or cotton in a mechanized way. It was developed in 18th-century Britain by Richard Arkwright and John Kay.

John Kay was an English inventor best known for the development of the spinning frame in 1767, which marked an important stage in the development of textile manufacturing during the Industrial Revolution. Born in Warrington in Lancashire, England, Kay was at least the co-constructor of the first spinning frame, and was a claimant to having been its inventor. He is sometimes confused with the unrelated John Kay from Bury, Lancashire, who had invented the flying shuttle, a weaving machine, some thirty years earlier.

Cotton-spinning machinery is machines which process prepared cotton roving into workable yarn or thread. Such machinery can be dated back centuries. During the 18th and 19th centuries, as part of the Industrial Revolution cotton-spinning machinery was developed to bring mass production to the cotton industry. Cotton spinning machinery was installed in large factories, commonly known as cotton mills.

Thomas Highs (1718–1803), of Leigh, Lancashire, was a reed-maker and manufacturer of cotton carding and spinning engines in the 1780s, during the Industrial Revolution. He is known for claiming patents on a spinning jenny, a carding machine and the throstle.

John Wyatt, an English inventor, was born near Lichfield and was related to Sarah Ford, Doctor Johnson's mother. A carpenter by trade he began work in Birmingham on the development of a spinning machine. In 1733 he was working in the mill at New Forge (Powells) Pool, Sutton Coldfield attempting to spin the first cotton thread ever spun by mechanical means.

Cromford Mill is the world's first water-powered cotton spinning mill, developed by Richard Arkwright in 1771 in Cromford, Derbyshire, England. The mill structure is classified as a Grade I listed building. It is now the centrepiece of the Derwent Valley Mills UNESCO World Heritage Site, and is a multi-use visitor centre with shops, galleries, restaurants and cafes.

Ring spinning is a spindle-based method of spinning fibres, such as cotton, flax or wool, to make a yarn. The ring frame developed from the throstle frame, which in its turn was a descendant of Arkwright's water frame. Ring spinning is a continuous process, unlike mule spinning which uses an intermittent action. In ring spinning, the roving is first attenuated by using drawing rollers, then spun and wound around a rotating spindle which in its turn is contained within an independently rotating ring flyer. Traditionally ring frames could only be used for the coarser counts, but they could be attended by semi-skilled labour.

The Upper Priory Cotton Mill, opened in Birmingham, England in the summer of 1741, was the world's first mechanised cotton-spinning factory or cotton mill. Established by Lewis Paul and John Wyatt in a former warehouse in the Upper Priory, near Paul's house in Old Square, it was the first of the Paul-Wyatt cotton mills that used the roller spinning machinery that they had developed and that had been patented by Paul in 1738, that for the first time enabled the spinning of cotton "without the aid of human fingers". Wyatt had realised that this machinery would enable several machines to be powered from a single source of power: foreseeing the development of the factory system, he envisaged "a kind of mill, with wheels turned either by horses, water or wind."

Marvel's Mill on the River Nene in Northampton, England, was the world's second factory for spinning cotton, the first to be operated as a water mill, and the first to be driven by an inanimate power-source. Opened by Edward Cave in 1742, it was one of the Paul-Wyatt cotton mills that used the roller spinning machinery invented by Lewis Paul and John Wyatt, which had first been used in their Upper Priory Cotton Mill in Birmingham in the summer of 1741.

Daniel Bourn was an English inventor, who took out a patent for a carding machine with rotating cylinders in 1748.

Kirk Mill is an early example of an Arkwright-type cotton mill and a grade II listed building in Chipping, Lancashire, in Ribble Valley, to the north of Preston, Lancashire, England. It was built in the 1780s on the site of a corn mill dating from at least 1544. The mill continued spinning cotton using water frames and then throstles until 1886, when it was sold and became HJ Berry's chairmaking factory. It was powered by a 32 ft (9.8 m) waterwheel which continued in use, generating electricity until the 1940s.

The Paul-Wyatt cotton mills were the world's first mechanised cotton spinning factories. Operating from 1741 until 1764 they were built to house the roller spinning machinery invented by Lewis Paul and John Wyatt. They were not very profitable but they span cotton successfully for several decades.

Pinsley Mill, also known as Etnam Street Mill, is a former watermill in Leominster, Herefordshire, England.

Samuel Touchet was an English cotton merchant, manufacturer and politician.