North East England is one of nine official regions of England at the first level of ITL for statistical purposes. The region has three current administrative levels below the region level in the region: combined authority, unitary authority or metropolitan borough, and civil parishes. They are also multiple divisions without administrative functions; ceremonial county, emergency services, built-up areas and historic county. The largest settlements in the region are Newcastle upon Tyne, Middlesbrough, Sunderland, Gateshead, Darlington, Hartlepool and Durham.

Teesside is a built-up area around the River Tees in North East England, split between County Durham and North Yorkshire. The area contains the towns of Middlesbrough, Stockton-on-Tees, Billingham, Redcar, Thornaby-on-Tees, and Ingleby Barwick. Teesside's economy was once dominated by heavy manufacturing until deindustrialisation in the latter half of the 20th century. Chemical production continues to contribute significantly to Teesside's economy.

The Leblanc process was an early industrial process for making soda ash used throughout the 19th century, named after its inventor, Nicolas Leblanc. It involved two stages: making sodium sulfate from sodium chloride, followed by reacting the sodium sulfate with coal and calcium carbonate to make sodium carbonate. The process gradually became obsolete after the development of the Solvay process.

Nicolas Leblanc was a French chemist and surgeon who discovered how to manufacture soda ash from common salt.

Sir Isaac Lowthian Bell, 1st Baronet, FRS was a Victorian ironmaster and Liberal Party politician from Washington, County Durham, in the north of England. He was described as being "as famous in his day as Isambard Kingdom Brunel".

Dorman Long & Co was a UK steel producer, later diversifying into bridge building. The company was once listed on the London Stock Exchange.

Grosmont is a village and civil parish situated in Eskdale in the North York Moors National Park, within the boundaries of the Scarborough district of the county of North Yorkshire, England.

An ironmaster is the manager, and usually owner, of a forge or blast furnace for the processing of iron. It is a term mainly associated with the period of the Industrial Revolution, especially in Great Britain.

Sir Thomas Hugh Bell, 2nd Baronet, was an English industrialist, landowner, Justice of the Peace, and administrator. A Deputy Lieutenant of County Durham, he was High Sheriff of Durham in 1895 and Lord Lieutenant of the North Riding of Yorkshire from 1906 to 1931. He joined his family firm, Bell Brothers, and became director of its steelworks at Middlesbrough.

William Losh was a chemist and industrialist who is credited with introducing the Leblanc process for the manufacture of alkali to the United Kingdom.

Bedlington Ironworks, in Blyth Dene, Northumberland, England, operated between 1736 and 1867. It is most remembered as the place where wrought iron rails were invented by John Birkinshaw in 1820, which triggered the railway age, with their first major use being in the Stockton and Darlington Railway opened in 1825, about 45 miles (72 km) to the south.

Henry William Ferdinand Bolckow, originally Heinrich Wilhelm Ferdinand Bölckow, was a Victorian industrialist and Member of Parliament, acknowledged as being one of the founders of modern Middlesbrough.

John Vaughan, known as Jacky, was born in Worcester on "St Thomas' Day" in 1799, the son of Welsh parents. He worked his way up the iron industry, becoming an ironmaster and co-founder of the largest of all the Victorian iron and steel companies, Bolckow Vaughan. Where Henry Bolckow provided the investment and business expertise, Vaughan contributed technical knowledge, in a long-lasting and successful partnership that transformed Middlesbrough from a small town to the centre of ironmaking in Britain.

The Consett Iron Company Ltd was an industrial business based in the Consett area of County Durham in the United Kingdom. The company owned coal mines and limestone quarries, and manufactured iron and steel. It was registered on 4 April 1864 as successor to the Derwent & Consett Iron Company Ltd. This in turn was the successor to the Derwent Iron Company, founded in 1840.

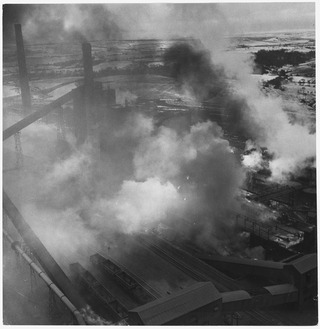

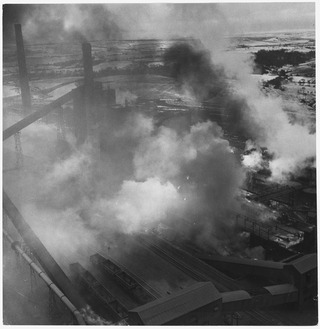

The Teesside Steelworks was a large steelworks that formed a continuous stretch along the south bank of the River Tees from the towns of Middlesbrough to Redcar in North Yorkshire, England. At its height there were 91 blast furnaces within a 10-mile radius of the area. By the end of the 1970s there was only one left on Teesside. Opened in 1979 and located near the mouth of the River Tees, the Redcar blast furnace was the second largest in Europe.

Thomas Wilson was a Tyneside poet, from Low Fell in County Durham. His most famous work, written in the Geordie dialect, is The Pitman's Pay, originally published between 1826 and 1830.

Bolckow, Vaughan & Co., Ltd was an English ironmaking and mining company founded in 1864, based on the partnership since 1840 of its two founders, Henry Bolckow and John Vaughan. The firm drove the dramatic growth of Middlesbrough and the production of coal and iron in the north-east of England in the 19th century. The two founding partners had an exceptionally close working relationship which lasted until Vaughan's death.

John Marley was an English mining engineer from Darlington who together with ironmaster John Vaughan made the "commercial discovery" of the Cleveland Ironstone Formation, the basis of the wealth of their company Bolckow Vaughan and the industrial growth of Middlesbrough. He was an effective leader of engineering operations at Bolckow Vaughan's mines and collieries. He ended his career as a wealthy independent mine-owner and president of the North of England Institute of Mining and Mechanical Engineers (NEIMME).

Skinningrove steelworks is a steel mill in Skinningrove, North Yorkshire, England. The business was formed in 1874 as the Loftus Iron Company, after a liquidation of the company reformed in 1880 as the Skinningrove Iron Company. The works expanded from producing only pig iron to include steel production in the early 20th century, with mills specialising in long products including railway rail. As part of the business the company constructed a jetty at Skinningrove, and owned an ironstone mine in Loftus.

Ironstone mining in Cleveland and North Yorkshire occurred on a sizeable scale from the 1830s to the 1960s in present day eastern parts of North Yorkshire but has been recorded as far back as Roman times in mostly a small-scale and intended for local use. This Cleveland is not to be confused with a smaller area covered by the county of Cleveland from 1974-96.