Related Research Articles

Configuration management (CM) is a systems engineering process for establishing and maintaining consistency of a product's performance, functional, and physical attributes with its requirements, design, and operational information throughout its life. The CM process is widely used by military engineering organizations to manage changes throughout the system lifecycle of complex systems, such as weapon systems, military vehicles, and information systems. Outside the military, the CM process is also used with IT service management as defined by ITIL, and with other domain models in the civil engineering and other industrial engineering segments such as roads, bridges, canals, dams, and buildings.

The BNC connector is a miniature quick connect/disconnect radio frequency connector used for coaxial cable. It is designed to maintain the same characteristic impedance of the cable, with 50 ohm and 75 ohm types being made. It is usually applied for video and radio frequency connections up to about 2 GHz and up to 500 volts. The connector has a twist to lock design with two lugs in the female portion of the connector engaging a slot in the shell of the male portion. The type was introduced on military radio equipment in the 1940s and has since become widely applied in radio systems, and is a common type of video connector. Similar radio-frequency connectors differ in dimensions and attachment features, and may allow for higher voltages, higher frequencies, or three-wire connections.

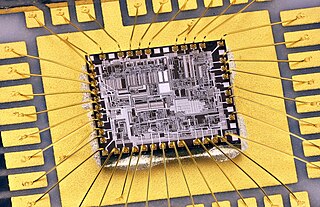

Wire bonding is the method of making interconnections between an integrated circuit (IC) or other semiconductor device and its packaging during semiconductor device fabrication. Although less common, wire bonding can be used to connect an IC to other electronics or to connect from one printed circuit board (PCB) to another. Wire bonding is generally considered the most cost-effective and flexible interconnect technology and is used to assemble the vast majority of semiconductor packages. Wire bonding can be used at frequencies above 100 GHz.

A line-replaceable unit (LRU), lower line-replaceable unit (LLRU), line-replaceable component (LRC), or line-replaceable item (LRI) is a modular component of an airplane, ship or spacecraft that is designed to be replaced quickly at an operating location. The different lines (distances) are essential for logistics planning and operation. An LRU is usually a sealed unit such as a radio or other auxiliary equipment. LRUs are typically assigned logistics control numbers (LCNs) or work unit codes (WUCs) to manage logistics operations.

The Initial Graphics Exchange Specification (IGES) is a vendor-neutral file format that allows the digital exchange of information among computer-aided design (CAD) systems. It is an ASCII-based textual format.

The presence of the logo on commercial products indicates that the manufacturer or importer affirms the goods' conformity with European health, safety, and environmental protection standards. It is not a quality indicator or a certification mark. The CE marking is required for goods sold in the European Economic Area (EEA); goods sold elsewhere may also carry the mark.

Reliability engineering is a sub-discipline of systems engineering that emphasizes the ability of equipment to function without failure. Reliability describes the ability of a system or component to function under stated conditions for a specified period of time. Reliability is closely related to availability, which is typically described as the ability of a component or system to function at a specified moment or interval of time.

A United States defense standard, often called a military standard, "MIL-STD", "MIL-SPEC", or (informally) "MilSpecs", is used to help achieve standardization objectives by the U.S. Department of Defense.

Integrated logistics support (ILS) is a technology in the system engineering to lower a product life cycle cost and decrease demand for logistics by the maintenance system optimization to ease the product support. Although originally developed for military purposes, it is also widely used in commercial customer service organisations.

Environmental stress screening (ESS) refers to the process of exposing a newly manufactured or repaired product or component to stresses such as thermal cycling and vibration in order to force latent defects to manifest themselves by permanent or catastrophic failure during the screening process. The surviving population, upon completion of screening, can be assumed to have a higher reliability than a similar unscreened population.

Product certification or product qualification is the process of certifying that a certain product has passed performance tests and quality assurance tests, and meets qualification criteria stipulated in contracts, regulations, or specifications.

The process of establishing documentary evidence demonstrating that a procedure, process, or activity carried out in testing and then production maintains the desired level of compliance at all stages. In the pharmaceutical industry, it is very important that in addition to final testing and compliance of products, it is also assured that the process will consistently produce the expected results. The desired results are established in terms of specifications for outcome of the process. Qualification of systems and equipment is therefore a part of the process of validation. Validation is a requirement of food, drug and pharmaceutical regulating agencies such as the US FDA and their good manufacturing practices guidelines. Since a wide variety of procedures, processes, and activities need to be validated, the field of validation is divided into a number of subsections including the following:

Electrical or fiber-optic connectors used by U.S. Department of Defense were originally developed in the 1930s for severe aeronautical and tactical service applications, and the Type "AN" (Army-Navy) series set the standard for modern military circular connectors. These connectors, and their evolutionary derivatives, are often called Military Standard, "MIL-STD", or (informally) "MIL-SPEC" or sometimes "MS" connectors. They are now used in aerospace, industrial, marine, and even automotive commercial applications.

The MIL-STD-883 standard establishes uniform methods, controls, and procedures for testing microelectronic devices suitable for use within military and aerospace electronic systems including basic environmental tests to determine resistance to deleterious effects of natural elements and conditions surrounding military and space operations; mechanical and electrical tests; workmanship and training procedures; and such other controls and constraints as have been deemed necessary to ensure a uniform level of quality and reliability suitable to the intended applications of those devices. For this standard, the term "devices" includes monolithic, multichip, film and hybrid microcircuits, microcircuit arrays, and the elements from which the circuits and arrays are formed. This standard is intended to apply only to microelectronic devices.

The MIL-PRF-38534 specification establishes the general performance requirements for hybrid microcircuits, multi-chip modules (MCM) and, similar devices and the verification and validation requirements for ensuring that these devices meet the applicable performance requirements. Verification is accomplished through the use of one of two quality programs. The main body of this specification describes the performance requirements and the requirements for obtaining a Qualified Manufacturers List (QML) listing. The appendices of this specification are intended for guidance to aid a manufacturer in developing their verification program. Detail requirements, specific characteristics, and other provisions that are sensitive to the particular intended use should be specified in the applicable device acquisition specification.

Flatpack is a US military standardized printed-circuit-board surface-mount-component package. The military standard MIL-STD-1835C defines: Flat package (FP). A rectangular or square package with leads parallel to base plane attached on two opposing sides of the package periphery.

In the United States military integrated acquisition lifecycle the Technical section has multiple acquisition "Technical Reviews". Technical reviews and audits assist the acquisition and the number and types are tailored to the acquisition. Overall guidance flows from the Defense Acquisition Guidebook chapter 4, with local details further defined by the review organizations. Typical topics examined include adequacy of program/contract metrics, proper staffing, risks, budget, and schedule.

An operating temperature is the allowable temperature range of the local ambient environment at which an electrical or mechanical device operates. The device will operate effectively within a specified temperature range which varies based on the device function and application context, and ranges from the minimum operating temperature to the maximum operating temperature. Outside this range of safe operating temperatures the device may fail.

Counterfeit electronic components are electronic parts whose origin or quality is deliberately misrepresented. Counterfeiting of electronic components can infringe on the legitimate producer's trademark rights. The marketing of electronic components has been commoditized, making it easier for counterfeiters to make it out into the supply chain.

Ballistic eyewear is a form of glasses or goggles that protect from small projectiles and fragments. For the U.S. military, choices are listed on the Authorized Protective Eyewear List (APEL). Ballistic eyewear including examples that meet APEL requirements are commercially available for anyone who wishes to buy it. The history of protective eyewear goes back to 1880 and extends through to World War I and the present. There are three standards that are currently used to test the effectiveness of ballistic eyewear. These include a U.S. civilian standard, a U.S. military standard (MIL-PRF-31013), and a European standard.

References

- ↑ "MIL-PRF-38535J, Performance Specification, Integrated Circuits (Microcircuits) Manufacturing, General Specification for". Department of Defense. 28 December 2010. Retrieved 4 June 2012.

- ↑ "Mil-PRF-38535". Defense Logistics Agency (DLA) Land and Maritime. Archived from the original on 18 February 2013. Retrieved 5 June 2012.

- ↑ "Mil-PRF-38535 Standard". siliconfareast.com. Retrieved 4 June 2012.

- ↑ "SD-6, Provisions Governing Qualification: Qualified Products Lists and Qualified Manufacturers Lists". United States Department of Defense – Defense Standardization Program. February 2009. Retrieved 5 June 2012.

- ↑ "DoD 4120.24-M – DSP Policies and Procedures ". Office of the Undersecretary of Defense (Acquisition, Technology and Logistics). March 2000. Archived from the original on 1 August 2012. Retrieved 5 June 2012.

- ↑ Winokur, P.S.; Sexton, F.W.; Fleetwood, D.M.; Terry, M.D.; Shaneyfelt, M.R.; Dressendorfer, P.V.; Schwank, J.R. (1990). "Implementing QML for radiation hardness assurance". IEEE Transactions on Nuclear Science. 37 (6): 1794–1805. doi:10.1109/23.101193. ISSN 0018-9499.