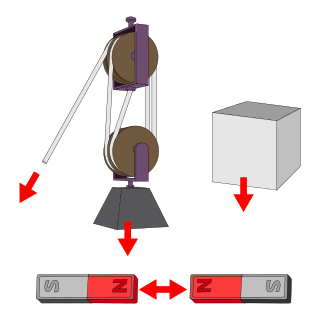

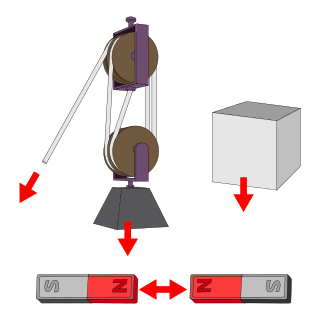

In physics, a force is any interaction that, when unopposed, will change the motion of an object. A force can cause an object with mass to change its velocity, i.e., to accelerate. Force can also be described intuitively as a push or a pull. A force has both magnitude and direction, making it a vector quantity. It is measured in the SI unit of newtons and represented by the symbol F.

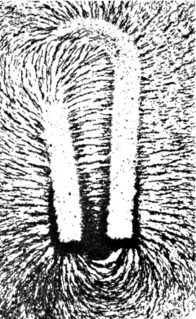

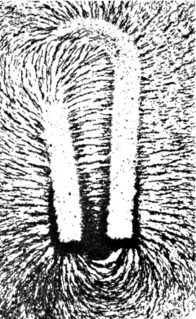

A magnetic field is a vector field that describes the magnetic influence of electric charges in relative motion and magnetized materials. The effects of magnetic fields are commonly seen in permanent magnets, which pull on magnetic materials and attract or repel other magnets. Magnetic fields surround and are created by magnetized material and by moving electric charges such as those used in electromagnets. They exert forces on nearby moving electrical charges and torques on nearby magnets. In addition, a magnetic field that varies with location exerts a force on magnetic materials. Both the strength and direction of a magnetic field vary with location. As such, it is described mathematically as a vector field.

The Zeeman effect, named after the Dutch physicist Pieter Zeeman, is the effect of splitting of a spectral line into several components in the presence of a static magnetic field. It is analogous to the Stark effect, the splitting of a spectral line into several components in the presence of an electric field. Also similar to the Stark effect, transitions between different components have, in general, different intensities, with some being entirely forbidden, as governed by the selection rules.

A solenoid is a type of electromagnet, the purpose of which is to generate a controlled magnetic field through a coil wound into a tightly packed helix. The coil can be arranged to produce a uniform magnetic field in a volume of space when an electric current is passed through it. The term solenoid was coined in 1823 by André-Marie Ampère to designate a helical coil.

Electrostatics is a branch of physics that studies electric charges at rest.

Tribology is the science and engineering of interacting surfaces in relative motion. It includes the study and application of the principles of friction, lubrication, and wear. Tribology is highly interdisciplinary. It draws on many academic fields, including physics, chemistry, materials science, mathematics, biology, and engineering. People who work in the field of tribology are referred to as tribologists.

Induction heating is the process of heating an electrically conducting object by electromagnetic induction, through heat generated in the object by eddy currents. An induction heater consists of an electromagnet and an electronic oscillator that passes a high-frequency alternating current (AC) through the electromagnet. The rapidly alternating magnetic field penetrates the object, generating electric currents inside the conductor, called eddy currents. The eddy currents flowing through the resistance of the material heat it by Joule heating. In ferromagnetic materials like iron, heat may also be generated by magnetic hysteresis losses. The frequency of current used depends on the object size, material type, coupling and the penetration depth.

In condensed matter physics, the Fermi surface is the surface in reciprocal space which separates occupied from unoccupied electron states at zero temperature. The shape of the Fermi surface is derived from the periodicity and symmetry of the crystalline lattice and from the occupation of electronic energy bands. The existence of a Fermi surface is a direct consequence of the Pauli exclusion principle, which allows a maximum of one electron per quantum state.

A magnetic circuit is made up of one or more closed loop paths containing a magnetic flux. The flux is usually generated by permanent magnets or electromagnets and confined to the path by magnetic cores consisting of ferromagnetic materials like iron, although there may be air gaps or other materials in the path. Magnetic circuits are employed to efficiently channel magnetic fields in many devices such as electric motors, generators, transformers, relays, lifting electromagnets, SQUIDs, galvanometers, and magnetic recording heads.

Electromagnetic shielding is the practice of reducing the electromagnetic field in a space by blocking the field with barriers made of conductive or magnetic materials. Shielding is typically applied to enclosures to isolate electrical devices from their surroundings, and to cables to isolate wires from the environment through which the cable runs. Electromagnetic shielding that blocks radio frequency (RF) electromagnetic radiation is also known as RF shielding.

Magnetic force microscopy (MFM) is a variety of atomic force microscopy, in which a sharp magnetized tip scans a magnetic sample; the tip-sample magnetic interactions are detected and used to reconstruct the magnetic structure of the sample surface. Many kinds of magnetic interactions are measured by MFM, including magnetic dipole–dipole interaction. MFM scanning often uses non-contact AFM (NC-AFM) mode.

In classical electromagnetism, magnetization or magnetic polarization is the vector field that expresses the density of permanent or induced magnetic dipole moments in a magnetic material. The origin of the magnetic moments responsible for magnetization can be either microscopic electric currents resulting from the motion of electrons in atoms, or the spin of the electrons or the nuclei. Net magnetization results from the response of a material to an external magnetic field. Paramagnetic materials have a weak induced magnetization in a magnetic field, which disappears when the magnetic field is removed. Ferromagnetic and ferrimagnetic materials have strong magnetization in a magnetic field, and can be magnetized to have magnetization in the absence of an external field, becoming a permanent magnet. Magnetization is not necessarily uniform within a material, but may vary between different points. Magnetization also describes how a material responds to an applied magnetic field as well as the way the material changes the magnetic field, and can be used to calculate the forces that result from those interactions. It can be compared to electric polarization, which is the measure of the corresponding response of a material to an electric field in electrostatics. Physicists and engineers usually define magnetization as the quantity of magnetic moment per unit volume. It is represented by a pseudovector M.

In physics, Larmor precession is the precession of the magnetic moment of an object about an external magnetic field. Objects with a magnetic moment also have angular momentum and effective internal electric current proportional to their angular momentum; these include electrons, protons, other fermions, many atomic and nuclear systems, as well as classical macroscopic systems. The external magnetic field exerts a torque on the magnetic moment,

In chemistry and physics, the exchange interaction is a quantum mechanical effect that only occurs between identical particles. Despite sometimes being called an exchange force in an analogy to classical force, it is not a true force as it lacks a force carrier.

A flux tube is a generally tube-like (cylindrical) region of space containing a magnetic field, B, such that the cylindrical sides of the tube are everywhere parallel to the magnetic field lines. It is a graphical visual aid for visualizing a magnetic field. Since no magnetic flux passes through the sides of the tube, the flux through any cross section of the tube is equal, and the flux entering the tube at one end is equal to the flux leaving the tube at the other. Both the cross-sectional area of the tube and the magnetic field strength may vary along the length of the tube, but the magnetic flux inside is always constant.

Ultrasonic machining, or strictly speaking the "Ultrasonic vibration machining", is a subtraction manufacturing process that removes material from the surface of a part through high frequency, low amplitude vibrations of a tool against the material surface in the presence of fine abrasive particles. The tool travels vertically or orthogonal to the surface of the part at amplitudes of 0.05 to 0.125 mm. The fine abrasive grains are mixed with water to form a slurry that is distributed across the part and the tip of the tool. Typical grain sizes of the abrasive material range from 100 to 1000, where smaller grains produce smoother surface finishes.

Grinding is an abrasive machining process that uses a grinding wheel as the cutting tool.

A Wien filter also known as velocity selector is a device consisting of perpendicular electric and magnetic fields that can be used as a velocity filter for charged particles, for example in electron microscopes and spectrometers. It is used in accelerator mass spectrometry to select particles based on their speed. The device is composed of orthogonal electric and magnetic fields, such that particles with the correct speed will be unaffected while other particles will be deflected. It is named for Wilhelm Wien who developed it in 1898 for the study of anode rays. It can be configured as a charged particle energy analyzer, monochromator, or mass spectrometer.

Static force fields are fields, such as a simple electric, magnetic or gravitational fields, that exist without excitations. The most common approximation method that physicists use for scattering calculations can be interpreted as static forces arising from the interactions between two bodies mediated by virtual particles, particles that exist for only a short time determined by the uncertainty principle. The virtual particles, also known as force carriers, are bosons, with different bosons associated with each force.

Lorentz force velocimetry (LFV) is a noncontact electromagnetic flow measurement technique. LFV is particularly suited for the measurement of velocities in liquid metals like steel or aluminium and is currently under development for metallurgical applications.The measurement of flow velocities in hot and aggressive liquids such as liquid aluminium and molten glass constitutes one of the grand challenges of industrial fluid mechanics. Apart from liquids, LFV can also be used to measure the velocity of solid materials as well as for detection of micro-defects in their structures.