Related Research Articles

Knitting is a method for production of textile fabrics by interlacing yarn loops with loops of the same or other yarns. It is used to create many types of garments. Knitting may be done by hand or by machine.

This timeline of clothing and textiles technology covers events relating to fiber and flexible woven material worn on the body. This includes the making, modification, usage, and knowledge of tools, machines, techniques, crafts, and manufacturing systems (technology).

In the manufacture of cloth, warp and weft are the two basic components in weaving to transform thread and yarn into textile fabrics. The vertical warp yarns are held stationary in tension on a loom (frame) while the horizontal weft is drawn through the warp thread. In the terminology of weaving, each warp thread is called a warp end ; a pick is a single weft thread that crosses the warp thread.

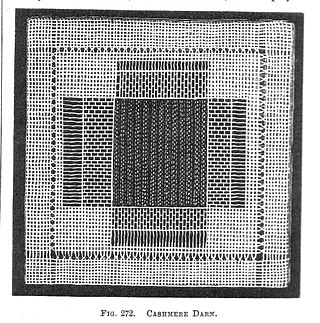

Darning is a sewing technique for repairing holes or worn areas in fabric or knitting using needle and thread alone. It is often done by hand, but using a sewing machine is also possible. Hand darning employs the darning stitch, a simple running stitch in which the thread is "woven" in rows along the grain of the fabric, with the stitcher reversing direction at the end of each row, and then filling in the framework thus created, as if weaving. Darning is a traditional method for repairing fabric damage or holes that do not run along a seam, and where patching is impractical or would create discomfort for the wearer, such as on the heel of a sock.

Textile manufacturing or textile engineering is a major industry. It is largely based on the conversion of fibre into yarn, then yarn into fabric. These are then dyed or printed, fabricated into cloth which is then converted into useful goods such as clothing, household items, upholstery and various industrial products.

Kasuri (絣) is the Japanese term for fabric that has been woven with fibers dyed specifically to create patterns and images in the fabric, typically referring to fabrics produced within Japan using this technique. It is a form of ikat dyeing, traditionally resulting in patterns characterized by their blurred or brushed appearance.

Plain weave is the most basic of three fundamental types of textile weaves. It is strong and hard-wearing, and is used for fashion and furnishing fabrics. Fabrics with a plain weave are generally strong, durable, and have a smooth surface. They are often used for a variety of applications, including clothing, home textiles, and industrial fabrics.

Warp knitting is defined as a loop-forming process in which the yarn is fed into the knitting zone, parallel to the fabric selvage. It forms vertical loops in one course and then moves diagonally to knit the next course. Thus the yarns zigzag from side to side along the length of the fabric. Each stitch in a course is made by many different yarns. Each stitch in one wale is made by several different yarns.

Knitted fabric is a textile that results from knitting, the process of inter-looping of yarns or inter-meshing of loops. Its properties are distinct from woven fabric in that it is more flexible and can be more readily constructed into smaller pieces, making it ideal for socks and hats.

A selvage or selvedge is a "self-finished" edge of a piece of fabric which keeps it from unraveling and fraying. The term "self-finished" means that the edge does not require additional finishing work, such as hem or bias tape, to prevent fraying.

The manufacture of textiles is one of the oldest of human technologies. To make textiles, the first requirement is a source of fiber from which a yarn can be made, primarily by spinning. The yarn is processed by knitting or weaving, which turns it into cloth. The machine used for weaving is the loom. For decoration, the process of colouring yarn or the finished material is dyeing. For more information of the various steps, see textile manufacturing.

Textile fibers, threads, yarns and fabrics are measured in a multiplicity of units.

Yarn weight refers to the thickness of yarn used by knitters, weavers, crocheters and other fiber artists.

Textile manufacturing is one of the oldest human activities. The oldest known textiles date back to about 5000 B.C. In order to make textiles, the first requirement is a source of fibre from which a yarn can be made, primarily by spinning. The yarn is processed by knitting or weaving to create cloth. The machine used for weaving is the loom. Cloth is finished by what are described as wet process to become fabric. The fabric may be dyed, printed or decorated by embroidering with coloured yarns.

Three-dimensional composites use fiber preforms constructed from yarns or tows arranged into complex three-dimensional structures. These can be created from a 3D weaving process, a 3D knitting process, a 3D braiding process, or a 3D lay of short fibers. A resin is applied to the 3D preform to create the composite material. Three-dimensional composites are used in highly engineered and highly technical applications in order to achieve complex mechanical properties. Three-dimensional composites are engineered to react to stresses and strains in ways that are not possible with traditional composite materials composed of single direction tows, or 2D woven composites, sandwich composites or stacked laminate materials.

Sewing is the craft of fastening or attaching objects using stitches made with needle and thread. Sewing is one of the oldest of the textile arts, arising in the Paleolithic Era. Although usually associated with clothing and household linens, sewing is used in a variety of crafts and industries, including shoemaking, upholstery, sailmaking, bookbinding and the manufacturing of some kinds of sporting goods. Sewing is the fundamental process underlying a variety of textile arts and crafts, including embroidery, tapestry, quilting, appliqué and patchwork.

String is a long flexible structure made from fibers twisted together into a single strand, or from multiple such strands which are in turn twisted together. String is used to tie, bind, or hang other objects. It is also used as a material to make things, such as textiles, and in arts and crafts. String is a simple tool, and its use by humans is known to have been developed tens of thousands of years ago. In Mesoamerica, for example, string was invented some 20,000 to 30,000 years ago, and was made by twisting plant fibers together. String may also be a component in other tools, and in devices as diverse as weapons, musical instruments, and toys.

An air-jet loom is a shuttleless loom that uses a jet of air to propel the weft yarn through the warp shed. It is one of two types of fluid-jet looms, the other being a water-jet loom, which was developed previously. Fluid-jet looms can operate at a faster speed than predecessor looms such as rapier looms, but they are not as common. The machinery used in fluid-jet weaving consists of a main nozzle, auxiliary nozzles or relay nozzles, and a profile reed.

3D textiles are three-dimensional structures made with different manufacturing methods such as weaving, knitting, braiding, or nonwoven, or made with alternative technologies. 3D textiles are produced with three planar geometry, opposed to 2D textiles that are made on two planes. The weave in 2D textiles is perpendicular. The yarn is fed along two axis: length (x-axis) and width (y-axis), while 3D textiles also have a perpendicular weave, but they have an extra yarn with an angular feeding (z-axis) which creates thickness. 3D weaves are orthogonal weave structures, multilayer structures, and angle interlocks. 3D textiles have more manufacturing opportunities, various properties, and a broader scope of applications. These textiles have a wide range of applications, but they are most commonly used where performance is the primary criterion, such as technical textiles. Composite materials, manufacturing is one of the significant areas of using 3D textiles.

Heinrich Mauersberger (1909–1982) was a German textile inventor. He is credited with inventing Malimo, a technique for stitch bonding, in 1949. He was awarded the patent DD000000008194A. The series of Malimo was further developed by the Chemnitz-based company Karl Mayer.

References

- ↑ Fung, W.; Hardcastle, J. M. (2000-11-28). Textiles in Automotive Engineering. Elsevier. p. 103. ISBN 978-1-85573-897-3.

- ↑ "Malimo Stitch-Bonding". www.swicofil.com. Retrieved 2021-09-25.

- ↑ "Application of stitch-bonded multi-plies made by using the extended warp knitting process: reinforcements with symmetrical layer arrangement for concrete | Hausding, Jan; Lorenz, Enrico; Ortlepp, Regine; Lundahl, Anna; Cherif, Chokri | download". ur.booksc.eu. Retrieved 2021-09-25.

- ↑ Gioello, Debbie Ann (1982). Understanding fabrics : from fiber to finished cloth. Internet Archive. New York : Fairchild Publications. p. 80. ISBN 978-0-87005-377-1.

- ↑ Resources, Apparel (2009-06-01). "KARL MAYER Pays Tribute to Knitting Master 'Heinrich Mauersberger' Innovates to Expand". Apparel Resources. Retrieved 2021-09-25.