Computer-aided manufacturing (CAM) also known as computer-aided modeling or computer-aided machining is the use of software to control machine tools in the manufacturing of work pieces. This is not the only definition for CAM, but it is the most common. It may also refer to the use of a computer to assist in all operations of a manufacturing plant, including planning, management, transportation and storage. Its primary purpose is to create a faster production process and components and tooling with more precise dimensions and material consistency, which in some cases, uses only the required amount of raw material, while simultaneously reducing energy consumption. CAM is now a system used in schools and lower educational purposes. CAM is a subsequent computer-aided process after computer-aided design (CAD) and sometimes computer-aided engineering (CAE), as the model generated in CAD and verified in CAE can be input into CAM software, which then controls the machine tool. CAM is used in many schools alongside CAD to create objects.

Mastercam is a suite of computer-aided manufacturing (CAM) and CAD/CAM software applications developed by CNC Software, LLC. Founded in Massachusetts in 1983, CNC Software are headquartered in Tolland, Connecticut.

In machining, numerical control, also called computer numerical control (CNC), is the automated control of tools by means of a computer. It is used to operate tools such as drills, lathes, mills, grinders, routers and 3D printers. CNC transforms a piece of material into a specified shape by following coded programmed instructions and without a manual operator directly controlling the machining operation.

G-code is the most widely used computer numerical control (CNC) and 3D printing programming language. It is used mainly in computer-aided manufacturing to control automated machine tools, as well as for 3D-printer slicer applications. The G stands for geometry. G-code has many variants.

CAD/CAM refers to the integration of Computer-aided design (CAD) and Computer-aided manufacturing (CAM). Both of these require powerful computers. CAD software helps designers and draftsmen; CAM "reduces manpower costs" in the manufacturing process.

CAD data exchange is a method of drawing data exchange used to translate between different computer-aided design (CAD) authoring systems or between CAD and other downstream CAx systems.

Direct numerical control (DNC), also known as distributed numerical control, is a common manufacturing term for networking CNC machine tools. On some CNC machine controllers, the available memory is too small to contain the machining program, so in this case the program is stored in a separate computer and sent directly to the machine, one block at a time. If the computer is connected to a number of machines it can distribute programs to different machines as required. Usually, the manufacturer of the control provides suitable DNC software. However, if this provision is not possible, some software companies provide DNC applications that fulfill the purpose. DNC networking or DNC communication is always required when CAM programs are to run on some CNC machine control.

A cutter location (CLData) refers to the position which a CNC milling machine has been instructed to hold a milling cutter by the instructions in the program.

Delcam is a supplier of advanced CAD/CAM software for the manufacturing industry. The company has grown steadily since being founded formally in 1977, after initial development work at Cambridge University, UK. It is now a global developer of product design and manufacturing software, with subsidiaries and joint ventures in North America, South America, Europe and Asia with a total staff of over 800 people and local support provided from over 300 re-seller offices worldwide. It was listed on the London Stock Exchange until 6 February 2014, when it was acquired by Autodesk. It now operates as a wholly owned, independently operated subsidiary of Autodesk.

STEP-NC is a machine tool control language that extends the ISO 10303 STEP standards with the machining model in ISO 14649, adding geometric dimension and tolerance data for inspection, and the STEP PDM model for integration into the wider enterprise. The combined result has been standardized as ISO 10303-238.

A computer numerical control (CNC) router is a computer-controlled cutting machine which typically mounts a hand-held router as a spindle which is used for cutting various materials, such as wood, composites, metals, plastics, glass, and foams. CNC routers can perform the tasks of many carpentry shop machines such as the panel saw, the spindle moulder, and the boring machine. They can also cut joinery such as mortises and tenons.

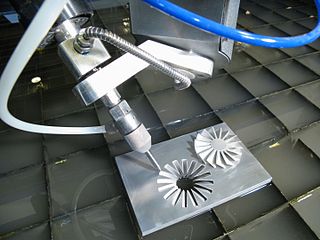

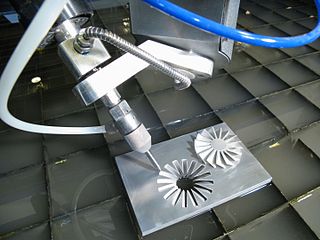

Multiaxis machining is a manufacturing process that involves tools that move in 4 or more directions and are used to manufacture parts out of metal or other materials by milling away excess material, by water jet cutting or by laser cutting. This type of machining was originally performed mechanically on large complex machines. These machines operated on 4, 5, 6, and even 12 axes which were controlled individually via levers that rested on cam plates. The cam plates offered the ability to control the tooling device, the table in which the part is secured, as well as rotating the tooling or part within the machine. Due to the machines size and complexity it took extensive amounts of time to set them up for production. Once computer numerically controlled machining was introduced it provided a faster, more efficient method for machining complex parts.

Guitar manufacturing is the use of machines, tools, and labor in the production of electric and acoustic guitars. This phrase may be in reference to handcrafting guitars using traditional methods or assembly line production in large quantities using modern methods. Guitar manufacturing can also be broken into several categories such as body manufacturing and neck manufacturing, among others. Guitar manufacturing includes the production of alto, classical, tenor, and bass tuned guitars.

LinuxCNC is a free, open-source Linux software system that implements numerical control capability using general purpose computers to control CNC machines. It's mainly intended to run on PC AMD x86-64 systems. Designed by various volunteer developers at linuxcnc.org, it is typically bundled as an ISO file with a modified version of Debian Linux which provides the required real-time kernel.

SmartCAM is a suite of Computer-Aided Manufacturing (CAM) and CAD/CAM software applications that uses toolpath modeling to assist CNC machinists in creating computer-numerically controlled (CNC) programs that direct CNC machine tools.

PowerMill is a 3D CAM solution that runs on Microsoft Windows for the programming of toolpaths for 5-axis CNC milling machines developed by Autodesk Inc. The software is used in a range of different engineering industries to determine optimal tool paths to reduce time and manufacturing costs as well as reduce tool loads and produce smooth surface finishes. More than 15,000 organisations use PowerMILL worldwide.

The history of numerical control (NC) began when the automation of machine tools first incorporated concepts of abstractly programmable logic, and it continues today with the ongoing evolution of computer numerical control (CNC) technology.

A Post Processor is a unique "driver" specific to a CNC machine, robot or mechanism; some machines start at different locations or require extra movement between each operation, the Post-Processor works with the CAM software or off-line programming software to make sure the G-Code output or program is correct for a specific Trademark machine Control Cabinet CAM software uses geometry from a CAD model and converts it to G-code. The CAM software analyzes the CAD model and determines what tooling and toolpaths will be used to mill the desired features. Doing so requires a CAM post processor that generates the exact G-code dialect used by the machine Control Module that is being targeted. An instance of such a translation is often referred to as a "post". There will be a different “post” for each G-code dialect the CAM software supports. Post Processors, rather the “post” uses an intermediate format that captures the G-code commands in a dialect-independent form. Most CAM software accomplishes this with an intermediate format called "CL.Data."