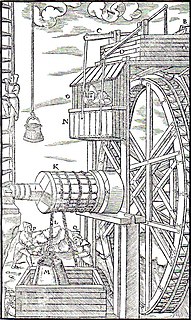

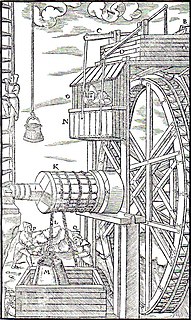

Mechanization is the process of changing from working largely or exclusively by hand or with animals to doing that work with machinery. In an early engineering text a machine is defined as follows:

Every machine is constructed for the purpose of performing certain mechanical operations, each of which supposes the existence of two other things besides the machine in question, namely, a moving power, and an object subject to the operation, which may be termed the work to be done. Machines, in fact, are interposed between the power and the work, for the purpose of adapting the one to the other.

The Industrial Age is a period of history that encompasses the changes in economic and social organization that began around 1760 in Great Britain and later in other countries, characterized chiefly by the replacement of hand tools with power-driven machines such as the power loom and the steam engine, and by the concentration of industry in large establishments.

Textile manufacture during the Industrial Revolution in Britain was centred in south Lancashire and the towns on both sides of the Pennines. In Germany it was concentrated in the Wupper Valley, Ruhr Region and Upper Silesia, in Spain it was concentrated in Catalonia while in the United States it was in New England. The main key drivers of the Industrial Revolution were textile manufacturing, iron founding, steam power, oil drilling, the discovery of electricity and its many industrial applications, the telegraph and many others. Railroads, steam boats, the telegraph and other innovations massively increased worker productivity and raised standards of living by greatly reducing time spent during travel, transportation and communications.

The Rheinisches Industriemuseum is a decentralized museum with six locations in Rhineland, western Germany. The locations are:

The factory system is a method of manufacturing using machinery and division of labour. This is because of the high capital cost of machinery and factory buildings, factories were typically privately owned by wealthy individuals who employed the operative labour. Use of machinery with the division of labour reduced the required skill level of workers and also increased the output per worker.

The textile industry is primarily concerned with the design, production and distribution of yarn, cloth and clothing. The raw material may be natural, or synthetic using products of the chemical industry.

A line shaft is a power-driven rotating shaft for power transmission that was used extensively from the Industrial Revolution until the early 20th century. Prior to the widespread use of electric motors small enough to be connected directly to each piece of machinery, line shafting was used to distribute power from a large central power source to machinery throughout a workshop or an industrial complex. The central power source could be a water wheel, turbine, windmill, animal power or a steam engine. Power was distributed from the shaft to the machinery by a system of belts, pulleys and gears known as millwork.

Greenwood & Batley were a large engineering manufacturer with a wide range of products, including armaments, electrical engineering, and printing and milling machinery. They also produced a range of battery-electric railway locomotives under the brand name Greenbat. The works was in Armley, Leeds, UK.

Bradford Industrial Museum, established 1974 in Moorside Mills, Eccleshill, Bradford, United Kingdom, specializes in relics of local industry, especially printing and textile machinery, kept in working condition for regular demonstrations to the public. There is a Horse Emporium in the old canteen block plus a shop in the mill, and entry is free of charge.

The Nottingham Industrial Museum is a volunteer-run museum situated in part of the 17th-century stables block of Wollaton Hall, located in a suburb of the city of Nottingham. The museum won the Nottinghamshire Heritage Site of the Year Award 2012, a local accolade issued by Experience Nottinghamshire. The Museum collection closed in 2009 after Nottingham City Council withdrew funding, but has since reopened at weekends and bank holidays, helped by a £91,000 government grant, and run by volunteers. The museum contains a display of local textiles machinery, transport, telecommunications, mining and engineering technology. There is a display of cycles, motorcycles, and motor cars. There are examples of significant lace-making machinery. It also houses an operational beam engine, from the Basford, Nottingham pumping station.

The Textilfabrik Cromford in Ratingen, North Rhine-Westphalia, Germany was built in 1783 by Johann Gottfried Brügelmann. It was the first cotton spinning mill on the European mainland. Today it is an industrial museum specialising in textile history.

The Baumwollspinnerei Ermen & Engels is a former cotton mill in Engelskirchen, Nordrhein-Westfalen, Germany. It is now part of the LVR Industrial Museum.

The machine industry or machinery industry is a subsector of the industry, that produces and maintains machines for consumers, the industry, and most other companies in the economy.

A machine factory is a company, that produces machines. These companies traditionally belong to the heavy industry sector in comparison to a more consumer oriented and less capital intensive light industry. Today many companies make more sophisticated smaller machines, and they belong to the light industry. The economic sector of machine factories is called the machine industry.

Queensland Woollen Manufacturing Company mill is a heritage-listed mill at 42 & 42B The Terrace, North Ipswich, City of Ipswich, Queensland, Australia. It is also known as Australian Fabric Manufacturers Ltd and Boral Hancock Plywood. It was added to the Queensland Heritage Register on 19 September 2008.

The Bocholt textile museum is a museum in Bocholt, a city in the north-west of North Rhine-Westphalia, Germany, part of the district Borken. It is situated 4 km south of the border with the Netherlands. The museum opened in 1989 as one of the eight locations of the LWL Industrial Museum: it is an Anchor point on the European Route of Industrial Heritage.

The Campolmi Factory, the Prato textile museum and Lazzerini Library is a textile museum and library in Prato in Tuscany, Italy. The museum is an Anchor point on the European Route of Industrial Heritage.

The Hendrich's Drop Forge part of the LVR Industriemuseum is a museum in Solingen, a city in North Rhine-Westphalia, Germany. It is located on the northern edge of the region called Bergisches Land, south of the Ruhr. The museum is an Anchor point on the European Route of Industrial Heritage.

The Medemblik steam museum or officially the Netherlands Steam Engine Museum is a historical and science museum in Medemblik, North-Holland, the Netherlands. Since 1985 the museum is located in a former pumping station, which was built in 1869 and decommissioned in 1979. The pumping station's installations are mostly still present and partly functioning. The museum is an anchor point on the European Route of Industrial Heritage, and the building and parts its interior are registered as a Rijksmonument, a national heritage site.

The Kommern Open Air Museum and Rhenish State Museum for Folk Art in Kommern/Eifel is one of the largest open air museums in Europe, covering an area of over 95 hectares and displaying around 67 historic buildings from the Prussian Rhine Province. It is operated by the Rhineland Regional Association.