Related Research Articles

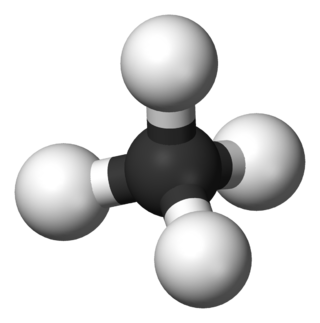

In organic chemistry, a hydrocarbon is an organic compound consisting entirely of hydrogen and carbon. Hydrocarbons are examples of group 14 hydrides. Hydrocarbons are generally colourless and hydrophobic; their odor is usually faint, and may be similar to that of gasoline or lighter fluid. They occur in a diverse range of molecular structures and phases: they can be gases, liquids, low melting solids or polymers.

Gasoline or petrol is a transparent, slight yellowish petroleum-derived flammable liquid that is used primarily as a fuel in most spark-ignited internal combustion engines. It consists mostly of organic compounds obtained by the fractional distillation of petroleum, enhanced with a variety of additives. On average, U.S. refineries produce, from a barrel of crude oil, about 19 to 20 gallons of gasoline; 11 to 13 gallons of distillate fuel ; and 3 to 4 gallons of jet fuel. The product ratio depends on the processing in an oil refinery and the crude oil assay.

Petrochemicals are the chemical products obtained from petroleum by refining. Some chemical compounds made from petroleum are also obtained from other fossil fuels, such as coal or natural gas, or renewable sources such as maize, palm fruit or sugar cane.

Naphtha is a flammable liquid hydrocarbon mixture. Generally, it is a fraction of crude oil, but it can also be produced from natural gas condensates, petroleum distillates, and the fractional distillation of coal tar and peat. In some industries and regions, the name naphtha refers to crude oil or refined petroleum products such as kerosene.

An oil refinery or petroleum refinery is an industrial process plant where petroleum is transformed and refined into useful products such as gasoline (petrol), diesel fuel, asphalt base, fuel oils, heating oil, kerosene, liquefied petroleum gas and petroleum naphtha. Petrochemical feedstock like ethylene and propylene can also be produced directly by cracking crude oil without the need of using refined products of crude oil such as naphtha. The crude oil feedstock has typically been processed by an oil production plant. There is usually an oil depot at or near an oil refinery for the storage of incoming crude oil feedstock as well as bulk liquid products. In 2020, the total capacity of global refineries for crude oil was about 101.2 million barrels per day.

Fuel oil is any of various fractions obtained from the distillation of petroleum. Such oils include distillates and residues. Fuel oils include heavy fuel oil, marine fuel oil (MFO), furnace oil (FO), gas oil (gasoil), heating oils, diesel fuel and others.

In petrochemistry, petroleum geology and organic chemistry, cracking is the process whereby complex organic molecules such as kerogens or long-chain hydrocarbons are broken down into simpler molecules such as light hydrocarbons, by the breaking of carbon-carbon bonds in the precursors. The rate of cracking and the end products are strongly dependent on the temperature and presence of catalysts. Cracking is the breakdown of a large hydrocarbons into smaller, more useful alkanes and alkenes. Simply put, hydrocarbon cracking is the process of breaking a long chain of hydrocarbons into short ones. This process requires high temperatures.

Petroleum ether is the petroleum fraction consisting of aliphatic hydrocarbons and boiling in the range 35–60 °C, and commonly used as a laboratory solvent. Despite the name, petroleum ether is not classified as an ether; the term is used only figuratively, signifying extreme lightness and volatility.

Catalytic reforming is a chemical process used to convert petroleum refinery naphthas distilled from crude oil into high-octane liquid products called reformates, which are premium blending stocks for high-octane gasoline. The process converts low-octane linear hydrocarbons (paraffins) into branched alkanes (isoparaffins) and cyclic naphthenes, which are then partially dehydrogenated to produce high-octane aromatic hydrocarbons. The dehydrogenation also produces significant amounts of byproduct hydrogen gas, which is fed into other refinery processes such as hydrocracking. A side reaction is hydrogenolysis, which produces light hydrocarbons of lower value, such as methane, ethane, propane and butanes.

A crude oil assay is the chemical evaluation of crude oil feedstocks by petroleum testing laboratories. Each crude oil type has unique molecular and chemical characteristics. No two crude oil types are identical and there are crucial differences in crude oil quality. The results of crude oil assay testing provide extensive detailed hydrocarbon analysis data for refiners, oil traders and producers. Assay data help refineries determine if a crude oil feedstock is compatible for a particular petroleum refinery or if the crude oil could cause yield, quality, production, environmental and other problems.

Demulsifiers, or emulsion breakers, are a class of specialty chemicals used to separate emulsions, for example, water in oil. They are commonly used in the processing of crude oil, which is typically produced along with significant quantities of saline water. This water must be removed from the crude oil prior to refining. If the majority of the water and salt are not removed, significant corrosion problems can occur in the refining process.

Crude oil is extracted from the bedrock before being processed in several stages, removing natural contaminants and undesirable hydrocarbons. This separation process produces mineral oil, which can in turn be denoted as paraffinic, naphthenic or aromatic. The differences between these different types of oils are not clear-cut, but mainly depend on the predominant hydrocarbon types in the oil. Paraffinic oil, for example, contains primarily higher alkanes, whereas naphthenic oils have a high share of cyclic alkanes in the mixture.

Gadiv Petrochemical Industries Ltd. גדיב תעשיות פטרוכימיה בע"מ, is an Israeli petrochemical company, part of Bazan Group owned by Israel Corporation Ltd. Gadiv offices are located in Haifa, Israel. The company manufactures and markets over 500 thousand tons of petrochemical products each year including aromatics, aliphatic solvents and intermediates for the chemical, pharmaceutical, plastic and food industries. Gadiv is wholly owned by Oil Refineries Ltd.

Petroleum naphtha is an intermediate hydrocarbon liquid stream derived from the refining of crude oil with CAS-no 64742-48-9. It is most usually desulfurized and then catalytically reformed, which rearranges or restructures the hydrocarbon molecules in the naphtha as well as breaking some of the molecules into smaller molecules to produce a high-octane component of gasoline.

Pyrolysis gasoline or Pygas is a naphtha-range product with high aromatics content. It is a by-product of high temperature naphtha cracking during ethylene and propylene production. Also, it is a high octane number mixture that contains aromatics, olefins, and paraffins ranging from C5s to C12s. The mixture has a CAS Number: 68477-58-7. PyGas has high potential for use as a gasoline blending mixture and/or as a source of aromatics. Currently, PyGas is generally used as a gasoline blending mixture due to its high octane number. Depending on the feedstock used to produce the olefins, steam cracking can produce a benzene-rich liquid by-product called pyrolysis gasoline. Pyrolysis gasoline can be blended with other hydrocarbons as a gasoline additive, or distilled to separate it into its components, including benzene.

Saturate, Aromatic, Resin and Asphaltene (SARA) is an analysis method that divides crude oil components according to their polarizability and polarity. The saturate fraction consists of nonpolar material including linear, branched, and cyclic saturated hydrocarbons (paraffins). Aromatics, which contain one or more aromatic rings, are slightly more polarizable. The remaining two fractions, resins and asphaltenes, have polar substituents. The distinction between the two is that asphaltenes are insoluble in an excess of heptane whereas resins are miscible with heptane.

In the petroleum refining and petrochemical industries, the initialism BTX refers to mixtures of benzene, toluene, and the three xylene isomers, all of which are aromatic hydrocarbons. The xylene isomers are distinguished by the designations ortho –, meta –, and para – as indicated in the adjacent diagram. If ethylbenzene is included, the mixture is sometimes referred to as BTEX.

PTT Global Chemical, also known as PTTGC, is a petrochemical company that specializes in synthesizing olefins and aromatics. It was founded in 2011 and is a subsidiary of PTT Public Company Limited.

IRPC Public Company Limited or simply IRPC is a Thai Public SET-listed Petroleum and Petrochemical company. It is a subsidiary of PTT Group, formerly Thai Petrochemical Industry Public Company Limited or "TPI", which was founded in 1978 by the Leophairatana family.

Petroleum benzine is a hydrocarbon-based solvent mixture that is classified by its physical properties rather than a specific chemical composition. This complicates distinction within the long list of petroleum distillate solvent mixtures: mineral spirits, naphtha, petroleum naptha, white gas, white spirits, turps substitute, mineral turpentine, petroleum ether, ligroin, and Stoddard solvent.

References

- ↑ "PONA Analysis (GC) : SHIMADZU (Shimadzu Corporation)" . Retrieved 8 March 2017.