Related Research Articles

Paint is any pigmented liquid, liquefiable, or solid mastic composition that, after application to a substrate in a thin layer, converts to a solid film. It is most commonly used to protect, color and primer, or provide texture. Paint can be made in many colors—and in many different types. Paint is typically stored, sold, and applied as a liquid, but most types dry into a solid. Most paints are either oil-based or water-based and each has distinct characteristics. For one, it is illegal in most municipalities to discard oil-based paint down household drains or sewers. Clean-up solvents are also different for water-based paint than they are for oil-based paint. Water-based paints and oil-based paints will cure differently based on the outside ambient temperature of the object being painted. Usually, the object being painted must be over 10 °C (50 °F), although some manufacturers of external paints/primers claim they can be applied when temperatures are as low as 2 °C (35 °F).

A pigment is a colored substance that is completely or nearly insoluble in water. In contrast, dyes are typically soluble, at least at some stage in their use. Generally dyes are often organic compounds whereas pigments are often inorganic compounds. Pigments of prehistoric and historic value include ochre, charcoal, and lapis lazuli.

The chemical industry comprises the companies that develop and produce industrial, specialty and other chemicals. Central to the modern world economy, it converts raw materials into industrial and consumer products. The plastics industry contains some overlap, as some chemical companies produce plastics as well as chemicals.

Acrylonitrile butadiene styrene (ABS) (chemical formula (C8H8)x·(C4H6)y·(C3H3N)z ) is a common thermoplastic polymer. Its glass transition temperature is approximately 105 °C (221 °F). ABS is amorphous and therefore has no true melting point.

Hair coloring, or hair dyeing, is the practice of changing the hair color. The main reasons for this are cosmetic: to cover gray or white hair, to alter hair to create a specific look, to change a colour to suit preference or to restore the original hair color after it has been discolored by hairdressing processes or sun bleaching.

Although PET is used in several applications,, as of 2022 only bottles are collected at a substantial scale. The main motivations have been either cost reduction or recycle content of retail goods. An increasing amount is recycled back into bottles, the rest goes into fibres, film, thermoformed packaging and strapping. After sorting, cleaning and grinding, 'bottle flake' is obtained, which is then processed by either:

Plastic recycling is the processing of plastic waste into other products. Recycling can reduce dependence on landfill, conserve resources and protect the environment from plastic pollution and greenhouse gas emissions. Recycling rates lag those of other recoverable materials, such as aluminium, glass and paper. Through 2015, the world produced some 6.3 billion tonnes of plastic waste, only 9% of which has been recycled, and only ~1% has been recycled more than once. Additionally, 12% was incinerated and the remaining 79% sent to landfill or to the environment including the ocean.

Bioplastics are plastic materials produced from renewable biomass sources, such as vegetable fats and oils, corn starch, straw, woodchips, sawdust, recycled food waste, etc. Some bioplastics are obtained by processing directly from natural biopolymers including polysaccharides and proteins, while others are chemically synthesised from sugar derivatives and lipids from either plants or animals, or biologically generated by fermentation of sugars or lipids. In contrast, common plastics, such as fossil-fuel plastics are derived from petroleum or natural gas.

Polyester is a category of polymers that contain the ester functional group in every repeat unit of their main chain. As a specific material, it most commonly refers to a type called polyethylene terephthalate (PET). Polyesters include naturally occurring chemicals, such as in plants and insects, as well as synthetics such as polybutyrate. Natural polyesters and a few synthetic ones are biodegradable, but most synthetic polyesters are not. Synthetic polyesters are used extensively in clothing.

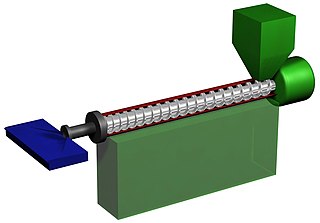

Plastics extrusion is a high-volume manufacturing process in which raw plastic is melted and formed into a continuous profile. Extrusion produces items such as pipe/tubing, weatherstripping, fencing, deck railings, window frames, plastic films and sheeting, thermoplastic coatings, and wire insulation.

Biodegradable plastics are plastics that can be decomposed by the action of living organisms, usually microbes, into water, carbon dioxide, and biomass. Biodegradable plastics are commonly produced with renewable raw materials, micro-organisms, petrochemicals, or combinations of all three.

A plastic bottle is a bottle constructed from high-density or low density plastic. Plastic bottles are typically used to store liquids such as water, soft drinks, motor oil, cooking oil, medicine, shampoo, milk, and ink. The size ranges from very small bottles to large carboys. Consumer blow molded containers often have integral handles or are shaped to facilitate grasping.

Polymer engineering is generally an engineering field that designs, analyses, and modifies polymer materials. Polymer engineering covers aspects of the petrochemical industry, polymerization, structure and characterization of polymers, properties of polymers, compounding and processing of polymers and description of major polymers, structure property relations and applications.

Plastics are a wide range of synthetic or semi-synthetic materials that use polymers as a main ingredient. Their plasticity makes it possible for plastics to be moulded, extruded or pressed into solid objects of various shapes. This adaptability, plus a wide range of other properties, such as being lightweight, durable, flexible, and inexpensive to produce, has led to its widespread use. Plastics typically are made through human industrial systems. Most modern plastics are derived from fossil fuel-based chemicals like natural gas or petroleum; however, recent industrial methods use variants made from renewable materials, such as corn or cotton derivatives.

Masterbatch (MB) is a solid additive used for coloring or imparting other properties to plastic. Masterbatch is a concentrated mixture of pigments and/or additives that is manufactured by encapsulation during a heat process or twin screw extrusion into a carrier matrix resin, which is then cooled and further cut into a granular shape. Masterbatch allows the processor to color raw polymer economically.

The term liquid color or liquid color concentrate describes to a system consisting of a liquid binder (carrier), dyes or pigments and other additives such as process additives, stabilisers or similar. The liquid colors are mixed into the plastic for coloring or changing the properties.

DIC Corporation is Japanese chemical company, specializing in the development, manufacture and sale of inks, pigments, polymers, specialty plastics and compounds and biochemicals.

Americhem, Inc. is a global masterbatch manufacturer that specializes in custom color and additive masterbatches, with its global headquarters in Cuyahoga Falls, Ohio. The company manufactures a diverse range of single pigment dispersions, color and additive concentrates and custom compounds. A sister company, Infinity LTL Engineered Compounds, manufactures custom compounded engineered thermoplastics, and has locations in Swedesboro, New Jersey, and Morrisville, Pennsylvania. Vi-Chem, acquired in 2016, is a producer of PVC and elastomeric compounds.

Laser welding of polymers is a set of methods used to join polymeric components through the use of a laser. It can be performed using CO2 lasers, Nd:YAG lasers, Diode lasers and Fiber lasers.

Made up of primary carbon, carbon black is spherical in shape and arranged into aggregates and agglomerates. It differs from other carbon forms in its complex configuration, colloid dimensions and quasi-graphitic structure. Carbon black's purity and composition are practically free of inorganic pollutants and extractable organic substances.

References

- ↑ Nishikants (2013-06-28). "Plastic colorant and its role in plastic industry". Share and Discover Knowledge on LinkedIn SlideShare. Retrieved 2017-07-18.

- ↑ "Plastic Colorants Guide for Injection Molded Parts". RevPart. 2016-01-26. Retrieved 2017-07-18.

- ↑ Sepe M (2012-01-28). "Working with Color Concentrates". Plastics Technology. Retrieved 2017-07-18.

- 1 2 "Colorants for Plastic Industry,Dyes for Plastics Industry,Pigments for Plastics Industry". Dyes and Pigments, Dyes Manufacturers, Dyes Intermediates, Pigments Suppliers, Wholesale Dyes Intermediates. Archived from the original on 2019-03-04. Retrieved 2017-07-18.

- ↑ "Toxics in Packaging Clearinghouse". Collation of Northeastern Governors (CONEG).

- ↑ "Methods of Coloring Plastics". RTP Company. October 2013. Retrieved 2017-07-18.

- ↑ "Effect of coloring methods on properties of plastics". Polyplastics.com. Retrieved 2017-07-18.