Polux is a measuring device for checking the condition of wooden electricity and telephone poles. This is a specific non-destructive testing tool for wooden poles.

Polux is a measuring device for checking the condition of wooden electricity and telephone poles. This is a specific non-destructive testing tool for wooden poles.

Polux technology is used for safety and maintenance diagnostics. The measurements enable operators to climb poles safely and check the condition of the wood to estimate its remaining lifespan. [1] [2] [3] [4]

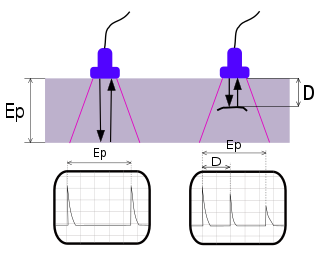

The Polux technology was developed in the early 90s by Professor Jean-Luc Sandoz, following on from the Sylvatest, at the initial request of EDF, which had the dual problem of the safety and lifespan of their poles. [5] In 2003, the technology was presented at the 17th International Congress on Electrical Distribution Networks in Barcelona. [6] In 2017, a report by Orange's CGT insisted on the danger of unmaintained poles and demonstrated, through several large-scale comparative tests, the scientific contribution of Polux technology to increasing the safety of personnel climbing poles, drawing on the experience of Enedis. [7] It works with Picus software, which uses data consisting of local densitometry measurements at the ground line and hygroscopic measurements. [8] [9] [10] The Polux technology continues to be developed at the CBS-Lifteam Research and Development Centre in Switzerland. [11] [12] The 5th version enables faster data collection and processing, with a miniaturised tool and the Picus application downloadable to smartphones. [13] [14] Polux technology is used in a number of countries, including the United States, Canada, European Union, Africa and Asia. [15] [16] [17]

• (en) Flávio L. R. Vidor, Marçal Pires, Berenice A. Dedavid, Pedro D. B. Montani, and Adriano Gabiatti, « », Rapport scientifique, 2010; [20]

• (br) M. A. O. Cruz1; M. Pires; B. A. Dedavid; F. L. R. Vidor; W. S. Oliveira; R. C.Abruzzi, « », revue scientifique,2010 (lire en ligne [PDF]).

Nondestructive testing (NDT) is any of a wide group of analysis techniques used in science and technology industry to evaluate the properties of a material, component or system without causing damage. The terms nondestructive examination (NDE), nondestructive inspection (NDI), and nondestructive evaluation (NDE) are also commonly used to describe this technology. Because NDT does not permanently alter the article being inspected, it is a highly valuable technique that can save both money and time in product evaluation, troubleshooting, and research. The six most frequently used NDT methods are eddy-current, magnetic-particle, liquid penetrant, radiographic, ultrasonic, and visual testing. NDT is commonly used in forensic engineering, mechanical engineering, petroleum engineering, electrical engineering, civil engineering, systems engineering, aeronautical engineering, medicine, and art. Innovations in the field of nondestructive testing have had a profound impact on medical imaging, including on echocardiography, medical ultrasonography, and digital radiography.

An inspection is, most generally, an organized examination or formal evaluation exercise. In engineering activities inspection involves the measurements, tests, and gauges applied to certain characteristics in regard to an object or activity. The results are usually compared to specified requirements and standards for determining whether the item or activity is in line with these targets, often with a Standard Inspection Procedure in place to ensure consistent checking. Inspections are usually non-destructive.

A utility pole is a column or post, usually made out of wood or aluminum alloy, used to support overhead power lines and various other public utilities, such as electrical cable, fiber optic cable, and related equipment such as transformers and street lights. It can be referred to as a transmission pole, telephone pole, telecommunication pole, power pole, hydro pole, telegraph pole, or telegraph post, depending on its application. A Stobie pole is a multi-purpose pole made of two steel joists held apart by a slab of concrete in the middle, generally found in South Australia.

The VDE e. V. is a German technical-scientific association. VDE is best known for creating and maintaining standards in the field of electric safety and has a strong influence on the DIN.

Eddy-current testing is one of many electromagnetic testing methods used in nondestructive testing (NDT) making use of electromagnetic induction to detect and characterize surface and sub-surface flaws in conductive materials.

Condition monitoring is the process of monitoring a parameter of condition in machinery, in order to identify a significant change which is indicative of a developing fault. It is a major component of predictive maintenance. The use of condition monitoring allows maintenance to be scheduled, or other actions to be taken to prevent consequential damages and avoid its consequences. Condition monitoring has a unique benefit in that conditions that would shorten normal lifespan can be addressed before they develop into a major failure. Condition monitoring techniques are normally used on rotating equipment, auxiliary systems and other machinery like belt-driven equipment,, while periodic inspection using non-destructive testing (NDT) techniques and fit for service (FFS) evaluation are used for static plant equipment such as steam boilers, piping and heat exchangers.

Ultrasonic testing (UT) is a family of non-destructive testing techniques based on the propagation of ultrasonic waves in the object or material tested. In most common UT applications, very short ultrasonic pulse waves with centre frequencies ranging from 0.1-15 MHz and occasionally up to 50 MHz, are transmitted into materials to detect internal flaws or to characterize materials. A common example is ultrasonic thickness measurement, which tests the thickness of the test object, for example, to monitor pipework corrosion and erosion. Ultrasonic testing is extensively used to detect flaws in welds.

Industrial radiography is a modality of non-destructive testing that uses ionizing radiation to inspect materials and components with the objective of locating and quantifying defects and degradation in material properties that would lead to the failure of engineering structures. It plays an important role in the science and technology needed to ensure product quality and reliability. In Australia, industrial radiographic non-destructive testing is colloquially referred to as "bombing" a component with a "bomb".

Weld quality assurance is the use of technological methods and actions to test or assure the quality of welds, and secondarily to confirm the presence, location and coverage of welds. In manufacturing, welds are used to join two or more metal surfaces. Because these connections may encounter loads and fatigue during product lifetime, there is a chance they may fail if not created to proper specification.

Alternating current field measurement (ACFM) is an electromagnetic technique for non-destructive testing detection and sizing of surface breaking discontinuities. It was derived from the methods used in eddy-current testing and works on all metals, ferrous or non-ferrous. Since it doesn't require direct electrical contact with the surface it can work through thin coatings such as paint. This practice is intended for use on welds in any metallic material.

A cover meter is an instrument to locate rebars and measure the exact concrete cover. Rebar detectors are less sophisticated devices that can only locate metallic objects below the surface. Due to the cost-effective design, the pulse-induction method is one of the most commonly used solutions.

Industrial computed tomography (CT) scanning is any computer-aided tomographic process, usually X-ray computed tomography, that uses irradiation to produce three-dimensional internal and external representations of a scanned object. Industrial CT scanning has been used in many areas of industry for internal inspection of components. Some of the key uses for industrial CT scanning have been flaw detection, failure analysis, metrology, assembly analysis and reverse engineering applications. Just as in medical imaging, industrial imaging includes both nontomographic radiography and computed tomographic radiography.

Terahertz nondestructive evaluation pertains to devices, and techniques of analysis occurring in the terahertz domain of electromagnetic radiation. These devices and techniques evaluate the properties of a material, component or system without causing damage.

Microwave imaging is a science which has been evolved from older detecting/locating techniques in order to evaluate hidden or embedded objects in a structure using electromagnetic (EM) waves in microwave regime. Engineering and application oriented microwave imaging for non-destructive testing is called microwave testing, see below.

Active thermography is an advanced nondestructive testing procedure, which uses a thermography measurement of a tested material thermal response after its external excitation. This principle can be used also for non-contact infrared non-destructive testing (IRNDT) of materials.

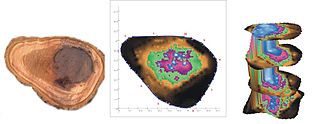

Acoustic or stress wave tomography is a non-destructive measurement method for the visualization of the structural integrity of a solid object. It is being used to test the preservation of wood or concrete, for example. The term acoustic tomography refers to the perceptible sounds that are caused by the mechanical impulses used for measuring. The term stress wave tomography describes the measurement method more accurately.

Giatec Scientific Inc. is a Canadian-based company with headquarters located in Ottawa, Ontario. It is a developer and manufacturer of nondestructive testing quality control and condition assessment devices for the construction industry.

Jean-Luc Sandoz is a French-Swiss engineer and an expert in wood construction. He is the founder of several companies in the field of engineering, industrialization, construction and expertise, all related to wood. Formerly, he was a professor and lecturer at EPFL.

Sylvatest is an ultrasonic measuring device that provides an overall diagnosis of a wooden component to test its mechanical strength. This is a specific non-destructive testing tool for wooden beams.

CBS-Lifteam is an international French-Swiss group, founded in 1991, specializing in timber engineering.