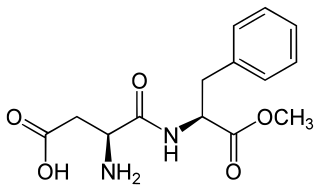

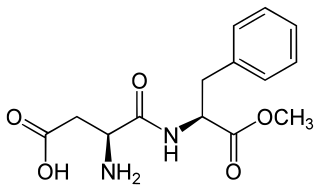

Aspartame is an artificial non-saccharide sweetener 200 times sweeter than sucrose and is commonly used as a sugar substitute in foods and beverages. It is a methyl ester of the aspartic acid/phenylalanine dipeptide with brand names NutraSweet, Equal, and Canderel. Aspartame was approved by the US Food and Drug Administration (FDA) in 1974, and then again in 1981, after approval was revoked in 1980.

Chocolate or cocoa is a food made from roasted and ground cacao seed kernels that is available as a liquid, solid, or paste, either on its own or as a flavoring agent in other foods. Cacao has been consumed in some form for at least 5,300 years starting with the Mayo-Chinchipe culture in what is present-day Ecuador and later Mesoamerican civilizations also consumed chocolate beverages before being introduced to Europe in the 16th century.

Castor oil is a vegetable oil pressed from castor beans. It is a colourless or pale yellow liquid with a distinct taste and odor. Its boiling point is 313 °C (595 °F) and its density is 0.961 g/cm3. It includes a mixture of triglycerides in which about 90% of fatty acids are ricinoleates. Oleic acid and linoleic acid are the other significant components.

Margarine is a spread used for flavoring, baking, and cooking. It is most often used as a substitute for butter. Although originally made from animal fats, most margarine consumed today is made from vegetable oil. The spread was originally named oleomargarine from Latin for oleum and Greek margarite. The name was later shortened to margarine.

Stearic acid is a saturated fatty acid with an 18-carbon chain. The IUPAC name is octadecanoic acid. It is a soft waxy solid with the formula CH3(CH2)16CO2H. The triglyceride derived from three molecules of stearic acid is called stearin. Stearic acid is a prevalent fatty-acid in nature, found in many animal and vegetable fats, but is usually higher in animal fat than vegetable fat. It has a melting point of 69.4 °C and a pKa of 4.50.

Lecithin is a generic term to designate any group of yellow-brownish fatty substances occurring in animal and plant tissues which are amphiphilic – they attract both water and fatty substances, and are used for smoothing food textures, emulsifying, homogenizing liquid mixtures, and repelling sticking materials.

Xanthan gum is a polysaccharide with many industrial uses, including as a common food additive. It is an effective thickening agent and stabilizer that prevents ingredients from separating. It can be produced from simple sugars by fermentation and derives its name from the species of bacteria used, Xanthomonas campestris.

Cocoa butter, also called theobroma oil, is a pale-yellow, edible fat extracted from the cocoa bean. It is used to make chocolate, as well as some ointments, toiletries, and pharmaceuticals. Cocoa butter has a cocoa flavor and aroma. Its melting point is slightly below human body temperature. It is an essential ingredient of chocolate and related confectionary products. Cocoa butter does not contain butter or other animal products; it is vegan.

White chocolate is a confectionery typically made of sugar, milk, and cocoa butter, but no cocoa solids. It is pale ivory in color, and lacks many of the compounds found in milk, dark, and other chocolates. It is solid at room temperature because the melting point of cocoa butter, the only white cocoa bean component, is 35 °C (95 °F).

Monoglycerides are a class of glycerides which are composed of a molecule of glycerol linked to a fatty acid via an ester bond. As glycerol contains both primary and secondary alcohol groups two different types of monoglycerides may be formed; 1-monoacylglycerols where the fatty acid is attached to a primary alcohol, or a 2-monoacylglycerols where the fatty acid is attached to the secondary alcohol.

Caramel color or caramel coloring is a water-soluble food coloring. It is made by heat treatment of carbohydrates (sugars), in general in the presence of acids, alkalis, or salts, in a process called caramelization. It is more fully oxidized than caramel candy, and has an odor of burnt sugar and a somewhat bitter taste. Its color ranges from pale yellow to amber to dark brown.

Compound chocolate is a product made from a combination of cocoa, vegetable fat and sweeteners. It is used as a lower-cost alternative to pure chocolate, as it uses less-expensive hard vegetable fats such as coconut oil or palm kernel oil in place of the more expensive cocoa butter. It may also be known as "compound coating" or "chocolatey coating" when used as a coating for candy. It is often used in less expensive chocolate bars to replace enrobed chocolate on a product.

Modified starch, also called starch derivatives, is prepared by physically, enzymatically, or chemically treating native starch to change its properties. Modified starches are used in practically all starch applications, such as in food products as a thickening agent, stabilizer or emulsifier; in pharmaceuticals as a disintegrant; or as binder in coated paper. They are also used in many other applications.

Ricinoleic acid, formally called 12-hydroxy-9-cis-octadecenoic acid, is a fatty acid. It is an unsaturated omega-9 fatty acid and a hydroxy acid. It is a major component of the seed oil obtained from the seeds of castor plant, the plant that produces ricin. It is also found in the sclerotium of ergot. About 90% of the fatty acid content in castor oil is the ricinolein.

Dry cocoa solids are the components of cocoa beans remaining after cocoa butter, the fatty component of the bean, is extracted from chocolate liquor, roasted cocoa beans that have been ground into a liquid state. Cocoa butter is 46% to 57% of the weight of cocoa beans and gives chocolate its characteristic melting properties. Cocoa powder is the powdered form of the dry solids with a small remaining amount of cocoa butter. Untreated cocoa powder is bitter and acidic. Dutch process cocoa has been treated with an alkali to neutralize the acid.

Mono- and diglycerides of fatty acids (E471) refers to a naturally occurring class of food additive composed of diglycerides and monoglycerides which is used as an emulsifier. It is also used as a fruit coating agent. This mixture is also sometimes referred to as partial glycerides.

An enrober is a machine used in the confectionery industry to coat a food item with a coating medium, typically chocolate. Foods that are coated by enrobers include nuts, ice cream, toffee, chocolate bars, biscuits and cookies. Enrobing with chocolate extends a confection's shelf life.

A diglyceride, or diacylglycerol (DAG), is a glyceride consisting of two fatty acid chains covalently bonded to a glycerol molecule through ester linkages. Two possible forms exist, 1,2-diacylglycerols and 1,3-diacylglycerols. Diglycerides are natural components of food fats, though minor in comparison to triglycerides. DAGs can act as surfactants and are commonly used as emulsifiers in processed foods. DAG-enriched oil has been investigated extensively as a fat substitute due to its ability to suppress the accumulation of body fat; with total annual sales of approximately USD 200 million in Japan since its introduction in the late 1990s till 2009.

Sucrose esters or sucrose fatty acid esters are a group of non-naturally occurring surfactants chemically synthesized from the esterification of sucrose and fatty acids. This group of substances is remarkable for the wide range of hydrophilic-lipophilic balance (HLB) that it covers. The polar sucrose moiety serves as a hydrophilic end of the molecule, while the long fatty acid chain serves as a lipophilic end of the molecule. Due to this amphipathic property, sucrose esters act as emulsifiers; i.e., they have the ability to bind both water and oil simultaneously. Depending on the HLB value, some can be used as water-in-oil emulsifiers, and some as oil-in-water emulsifiers. Sucrose esters are used in cosmetics, food preservatives, food additives, and other products. A class of sucrose esters with highly substituted hydroxyl groups, olestra, is also used as a fat replacer in food.