A rack and pinion is a type of linear actuator that comprises a circular gear engaging a linear gear. Together, they convert rotational motion into linear motion. Rotating the pinion causes the rack to be driven in a line. Conversely, moving the rack linearly will cause the pinion to rotate. A rack and pinion drive can use both straight and helical gears. Though some suggest helical gears are quieter in operation, no hard evidence supports this theory. Helical racks, while being more affordable, have proven to increase side torque on the datums, increasing operating temperature leading to premature wear. Straight racks require a lower driving force and offer increased torque and speed per percentage of gear ratio which allows lower operating temperature and lessens viscal friction and energy use. The maximum force that can be transmitted in a rack and pinion mechanism is determined by the tooth pitch and the size of the pinion as well as the gear ratio.

Steering is a system of components, linkages, and other parts that allows a driver to control the direction of a vehicle.

An actuator is a component of a machine that is responsible for moving and controlling a mechanism or system, for example by opening a valve. In simple terms, it is a "mover".

A zipper, zip, fly, or zip fastener, formerly known as a clasp locker, is a commonly used device for binding together two edges of fabric or other flexible material. Used in clothing, luggage and other bags, camping gear, and many other items, zippers come in a wide range of sizes, shapes, and colors. In 1892, Whitcomb L. Judson, an American inventor from Chicago, patented the original design from which the modern device evolved.

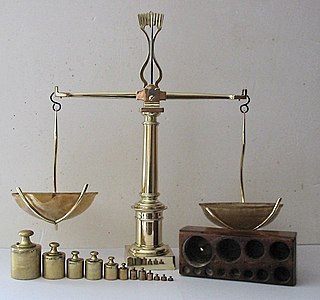

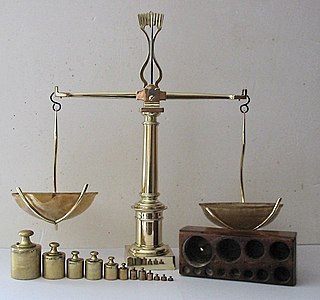

A scale or balance is a device used to measure weight or mass. These are also known as mass scales, weight scales, mass balances, and weight balances.

A Slip sheet is “a corrugated, solid fiber, or plastic sheet onto which a unit load can be assembled. A protruding short panel can be grasped by the jaws of a pull-pack truck and the load pulled back onto the pull-pack platform.”

A linear actuator is an actuator that creates motion in a straight line, in contrast to the circular motion of a conventional electric motor. Linear actuators are used in machine tools and industrial machinery, in computer peripherals such as disk drives and printers, in valves and dampers, and in many other places where linear motion is required. Hydraulic or pneumatic cylinders inherently produce linear motion. Many other mechanisms are used to generate linear motion from a rotating motor.

A linear-motion bearing or linear slide is a bearing designed to provide free motion in one direction. There are many different types of linear motion bearings.

A jack is a mechanical lifting device used to apply great forces or lift heavy loads. A mechanical jack employs a screw thread for lifting heavy equipment. A hydraulic jack uses hydraulic power. The most common form is a car jack, floor jack or garage jack, which lifts vehicles so that maintenance can be performed. Jacks are usually rated for a maximum lifting capacity. Industrial jacks can be rated for many tons of load.

Anchor bolts are used to connect structural and non-structural elements to concrete. The connection can be made by a variety of different components: anchor bolts, steel plates, or stiffeners. Anchor bolts transfer different types of load: tension forces and shear forces.

A chain is a serial assembly of connected pieces, called links, typically made of metal, with an overall character similar to that of a rope in that it is flexible and curved in compression but linear, rigid, and load-bearing in tension. A chain may consist of two or more links. Chains can be classified by their design, which can be dictated by their use:

A tensioner is a device that applies a force to create or maintain tension. The force may be applied parallel to, as in the case of a hydraulic bolt tensioner, or perpendicular to, as in the case of a spring-loaded bicycle chain tensioner, the tension it creates. The force may be generated by a fixed displacement, as in the case of an eccentric bicycle bottom bracket, which must be adjusted as parts wear, or by stretching or compressing a spring, as in the case of a spring-loaded bicycle chain tensioner; by changing the volume of a gas, as in the case of a marine riser tensioner; by hydraulic pressure, as in the case of a hydraulic bolt tensioner; or by gravity acting on a suspended mass, as in the case of a chair lift cable tensioner. In the power sector, the tensioner is a machine for maintaining constant tension of the conductors during work of hanging the transmission network..

Pallet rack is a material handling storage aid system designed to store materials on pallets. Although there are many varieties of pallet racking, all types allow for the storage of palletized materials in horizontal rows with multiple levels. Forklift trucks are usually required to place the loaded pallets onto the racks for storage. Since the Second World War, pallet racks have become a ubiquitous element of most modern warehouses, manufacturing facilities, retail centers, and other storage and distribution facilities. All types of pallet racking increase storage density of the stored goods. Costs associated with the racking increases with increasing storage density.

Material handling equipment (MHE) is mechanical equipment used for the movement, storage, control, and protection of materials, goods and products throughout the process of manufacturing, distribution, consumption, and disposal. The different types of equipment can be classified into four major categories: transport equipment, positioning equipment, unit load formation equipment, and storage equipment.

A conveyor system is a common piece of mechanical handling equipment that moves materials from one location to another. Conveyors are especially useful in applications involving the transport of heavy or bulky materials. Conveyor systems allow quick and efficient transport for a wide variety of materials, which make them very popular in the material handling and packaging industries. They also have popular consumer applications, as they are often found in supermarkets and airports, constituting the final leg of item/ bag delivery to customers. Many kinds of conveying systems are available and are used according to the various needs of different industries. There are chain conveyors as well. Chain conveyors consist of enclosed tracks, I-Beam, towline, power & free, and hand pushed trolleys.

A checkweigher is an automatic or manual machine for checking the weight of packaged commodities. It is normally found at the offgoing end of a production process and is used to ensure that the weight of a pack of the commodity is within specified limits. Any packs that are outside the tolerance are taken out of line automatically.

A segmented spindle, also known by the trademark Kataka, is a specialized mechanical linear actuator conceived by the Danish mechanical engineer Jens Joerren Soerensen during the mid-1990s. The actuator forms a telescoping tubular column, or spindle, from linked segments resembling curved parallelograms. The telescoping linear actuator has a lifting capacity up to 200 kg for a travel of 400 mm (~15.75 inches).

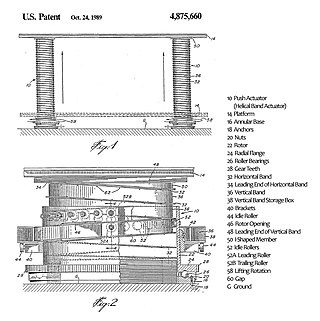

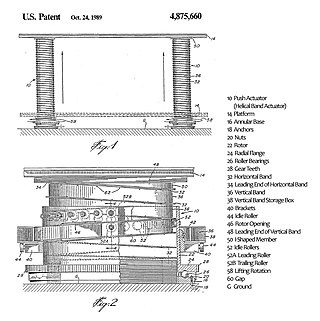

A helical band actuator, generally known by the trademark Spiralift, is a complex and specialized linear actuator used in stage lifts and material handling lifts. The actuator forms a high-capacity telescoping tubular column.

A rigid chain actuator, known variously as a linear chain actuator, push-pull chain actuator, electric chain actuator or column-forming chain actuator, is a specialized mechanical linear actuator used in window operating, push-pull material handling and lift applications. The actuator is a chain and pinion device that forms an articulated telescoping member to transmit traction and thrust. High-capacity rigid chain lifting columns (jacks) can move dynamic loads exceeding 10 tonnes (22,000 lb) over more than 7 metres (23 ft) of travel.