The M198 is a medium-sized, towed 155 mm artillery piece, developed for service with the United States Army and Marine Corps. It was commissioned to be a replacement for the World War II-era M114 155 mm howitzer. It was designed and prototyped at the Rock Island Arsenal in 1969 with firing tests beginning in 1970 and went into full production there in 1978. It entered service in 1979 and since then 1,600 units have been produced.

The M109 is an American 155 mm turreted self-propelled howitzer, first introduced in the early 1960s to replace the M44. It has been upgraded a number of times, most recently to the M109A7. The M109 family is the most common Western indirect-fire support weapon of maneuver brigades of armored and mechanized infantry divisions.

The AS-90, known officially as Gun Equipment 155 mm L131, is an armoured self-propelled artillery used by the British Army.

The M107 is a 155 mm high explosive projectile used by many countries. It is a bursting round with fragmentation and blast effects. It used to be the standard 155 mm high explosive projectile for howitzers of the US Army and US Marine Corps, but is being superseded in the US military by the M795.

A mortar is usually a simple, lightweight, man-portable, muzzle-loaded weapon, consisting of a smooth-bore metal tube fixed to a base plate with a lightweight bipod mount and a sight. They launch explosive shells in high-arcing ballistic trajectories. Mortars are typically used as indirect fire weapons for close fire support with a variety of ammunition.

A dual-purpose improved conventional munition (DPICM) is an artillery or surface-to-surface missile warhead designed to burst into submunitions at an optimum altitude and distance from the desired target for dense area coverage. The submunitions use both shaped charges for the anti-armor role, and fragmentation for the antipersonnel role, hence the nomenclature "dual-purpose". Some submunitions may be designed for delayed reaction or mobility denial (mines). The air-to-surface variety of this kind of munition is better known as a cluster bomb. They are banned by more than 100 countries under the Convention on Cluster Munitions.

The Tooele Chemical Agent Disposal Facility or TOCDF, is a U.S. Army facility located at Deseret Chemical Depot in Tooele County, Utah that was used for dismantling chemical weapons.

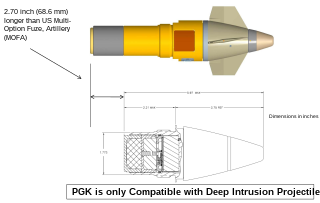

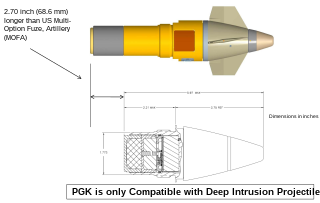

The M1156 Precision Guidance Kit (PGK), formerly XM1156, is a U.S. Army-designed precision guidance system to turn existing 155 mm artillery shells into smart weapons. The prime contractor was Alliant Techsystems – later merging with Orbital Sciences Corporation to form Orbital ATK, in turn being taken over by Northrop Grumman and renamed Northrop Grumman Innovation Systems – and the industry team includes Interstate Electronics Corporation. By April 2018, more than 25,000 PGKs had been produced.

Lake City Army Ammunition Plant (LCAAP) is a 3,935-acre (15.92 km2) U.S. government-owned, contractor-operated facility in northeastern Independence, Missouri, that was established by Remington Arms in 1941 to manufacture and test small caliber ammunition for the U.S. Army. The facility has remained in continuous operation except for one 5-year period following World War II. As of July 2007, the plant produced nearly 1.4 billion rounds of ammunition per year. In addition, Lake City performs small caliber ammunition stockpile reliability testing and has ammunition and weapon testing responsibilities as the NATO National and Regional Test Center. LCAAP is the single largest producer of small arms ammunition for the United States Armed Forces.

The Blue Grass Chemical Agent-Destruction Pilot Plant (BGCAPP) is a facility built to destroy the chemical weapons stockpile at the Blue Grass Army Depot (BGAD), near Richmond, Kentucky.

The Joint Munitions Command (JMC) is the latest in a series of commands since World War II that have managed the ammunition plants of the United States. Since 1973, those commands have been headquartered on Rock Island Arsenal. Brigadier General Gavin J. Gardner commands the JMC. The headquarters on Rock Island Arsenal is responsible for munitions production and storage (depots) facilities in 16 states. JMC employs 20 military, over 5800 civilians and 8300 contractor personnel. Of these approximately 14,000 personnel, more than 650 work in the headquarters on Rock Island Arsenal. JMC has an annual budget of 1.2 billion dollars.

The Iowa Army Ammunition Plant (IAAAP), located in Des Moines County in southeastern Iowa, near the city of Burlington, produces and delivers component assembly, and medium- and large-caliber ammunition items for the United States Department of Defense using modern production methods in support of worldwide operations. The facility is part of the US Army Joint Munitions Command.

Crane Army Ammunition Activity (CAAA) in Crane, Indiana produces and provides conventional munitions requirements in support of United States Army and Joint Force readiness. It is one of 17 installations of the Joint Munitions Command and one of 23 organic industrial bases under the U.S. Army Materiel Command, which include arsenals, depots, activities and ammunition plants. Established in October 1977, it is located on Naval Support Activity Crane.

The last chemical weapon in the U.S. stockpile was destroyed July 7, 2023, at the Blue Grass Chemical Agent-Destruction Pilot Plant.

The Pueblo Chemical Agent-Destruction Pilot Plant (PCAPP) is a chemical weapons destruction facility built to destroy the chemical weapons stockpile formerly stored at the U.S. Army Pueblo Chemical Depot (PCD) in southeastern Colorado. The stockpile originally contained 2,613 U.S. tons of mustard agent in 155mm projectiles, 105mm projectiles and 4.2-inch mortar rounds. The weapons had been stored at the 23,000-acre depot since the 1950s.

The Kansas Army Ammunition Plant was a 13,727-acre (55.55 km2) government-owned, contractor-operated (GOCO) facility, established in 1942, located near Parsons, Kansas. The plant produced ammunition during World War II, the Korean War, and the Vietnam War. The plant was deactivated on March 4, 2009 as part of the Base Realignment and Closure, 2005.

IMX-101 is a high-performance insensitive high explosive composite mixture developed by BAE Systems and the United States Army to replace TNT in artillery shells. IMX stands for "Insensitive Munitions eXplosives", which refers to the purpose of IMX-101: to provide explosive force equivalent to TNT without its sensitivity to shocks such as gunfire, explosions from improvised explosive devices, fire, and shrapnel. For example, it is believed that a training incident in Nevada which killed seven Marines would not have occurred with the new explosive. On March 23, 2013, the United States Army ordered $780 million worth of the explosive, with a production of millions of pounds annually, to be produced by BAE at Holston Army Ammunition Plant in Tennessee. The new explosive will cost $8 per pound, compared to $6 per pound for TNT. As of 2023, IMX-101 filled shells are being used in the 2022 Russian invasion of Ukraine.

The SMArt 155 is a German 155 mm artillery round designed for a long-range, indirect fire top-attack role against armoured vehicles. The projectile was developed in 1989 by Diehl BGT Defence in Überlingen, Germany, with Rheinmetall and started full-rate production for the German Army in 1998. It consists of a 47-kilogram (104 lb) heavy artillery projectile containing two autonomous, sensor-fused, "fire-and-forget" submunitions. Due to the submunitions, it has been considered by some to be a cluster munition. As of 2008, representatives of the German defense ministry have referred to it as not being classified as submunition weapons, which were prohibited by the 2008 Convention on Cluster Munitions.

The M795 155mm projectile is the US Army and US Marine Corps' standard 155mm High Explosive (HE) projectile for howitzers. It is a bursting round with fragmentation and blast effects.