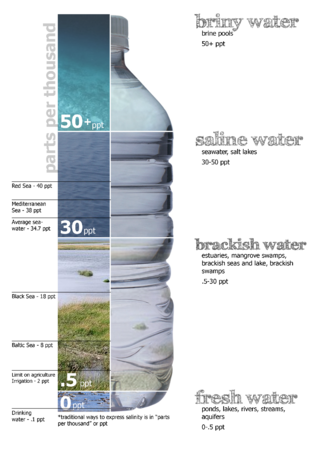

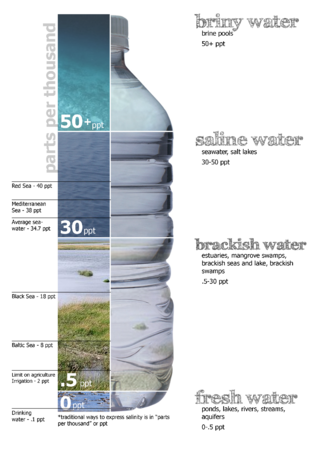

Brine is water with a high-concentration solution of salt. In diverse contexts, brine may refer to the salt solutions ranging from about 3.5% up to about 26%. Brine forms naturally due to evaporation of ground saline water but it is also generated in the mining of sodium chloride. Brine is used for food processing and cooking, for de-icing of roads and other structures, and in a number of technological processes. It is also a by-product of many industrial processes, such as desalination, so it requires wastewater treatment for proper disposal or further utilization.

Desalination is a process that takes away mineral components from saline water. More generally, desalination is the removal of salts and minerals from a target substance, as in soil desalination, which is an issue for agriculture. Saltwater is desalinated to produce water suitable for human consumption or irrigation. The by-product of the desalination process is brine. Desalination is used on many seagoing ships and submarines. Most of the modern interest in desalination is focused on cost-effective provision of fresh water for human use. Along with recycled wastewater, it is one of the few rainfall-independent water resources.

Geothermal desalination refers to the process of using geothermal energy to power the process of converting salt water to fresh water. The process is considered economically efficient, and while overall environmental impact is uncertain, it has potential to be more environmentally friendly compared to conventional desalination options. Geothermal desalination plants have already been successful in various regions, and there is potential for further development to allow the process to be used in an increased number of water scarce regions.

Forward osmosis (FO) is an osmotic process that, like reverse osmosis (RO), uses a semi-permeable membrane to effect separation of water from dissolved solutes. The driving force for this separation is an osmotic pressure gradient, such that a "draw" solution of high concentration, is used to induce a net flow of water through the membrane into the draw solution, thus effectively separating the feed water from its solutes. In contrast, the reverse osmosis process uses hydraulic pressure as the driving force for separation, which serves to counteract the osmotic pressure gradient that would otherwise favor water flux from the permeate to the feed. Hence significantly more energy is required for reverse osmosis compared to forward osmosis.

A solar still distills water with substances dissolved in it by using the heat of the Sun to evaporate water so that it may be cooled and collected, thereby purifying it. They are used in areas where drinking water is unavailable, so that clean water is obtained from dirty water or from plants by exposing them to sunlight.

Solar desalination is a desalination technique powered by solar energy. The two common methods are direct (thermal) and indirect (photovoltaic).

An atmospheric water generator (AWG), is a device that extracts water from humid ambient air, producing potable water. Water vapor in the air can be extracted either by condensation - cooling the air below its dew point, exposing the air to desiccants, using membranes that only pass water vapor, collecting fog, or pressurizing the air. AWGs are useful where potable water is difficult to obtain, because water is always present in ambient air.

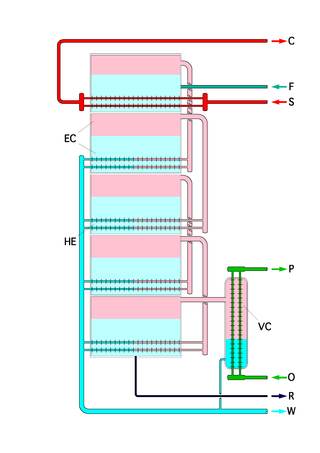

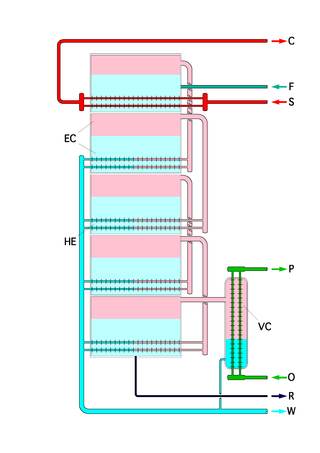

The solar humidification–dehumidification method (HDH) is a thermal water desalination method. It is based on evaporation of sea water or brackish water and subsequent condensation of the generated humid air, mostly at ambient pressure. This process mimics the natural water cycle, but over a much shorter time frame.

Dewvaporation is a novel desalination technology developed at Arizona State University (Tempe) as an energy efficient tool for freshwater procurement and saline waste stream management. The system has relatively low installation costs and low operation and maintenance requirements.

An evaporator is a type of heat exchanger device that facilitates evaporation by utilizing conductive and convective heat transfer to provide the necessary thermal energy for phase transition from liquid to vapor. Within evaporators, a circulating liquid is exposed to an atmospheric or reduced pressure environment, causing it to boil at a lower temperature compared to normal atmospheric boiling.

Evaporation ponds are artificial ponds with very large surface areas that are designed to efficiently evaporate water by sunlight and expose water to the ambient temperatures. Evaporation ponds are inexpensive to design making it ideal for multiple purposes such as wastewater treatment processes, storage, and extraction of minerals. Evaporation ponds differ in usage and result in a wide range of environmental and health effects.

A solar-powered desalination unit produces potable water from saline water through direct or indirect methods of desalination powered by sunlight. Solar energy is the most promising renewable energy source due to its ability to drive the more popular thermal desalination systems directly through solar collectors and to drive physical and chemical desalination systems indirectly through photovoltaic cells.

Reverse osmosis (RO) is a water purification process that uses a semi-permeable membrane to separate water molecules from other substances. RO applies pressure to overcome osmotic pressure that favors even distributions. RO can remove dissolved or suspended chemical species as well as biological substances, and is used in industrial processes and the production of potable water. RO retains the solute on the pressurized side of the membrane and the purified solvent passes to the other side. It relies on the relative sizes of the various molecules to decide what passes through. "Selective" membranes reject large molecules, while accepting smaller molecules.

Desert greening is the process of afforestation or revegetation of deserts for ecological restoration (biodiversity), sustainable farming and forestry, but also for reclamation of natural water systems and other ecological systems that support life. The term "desert greening" is intended to apply to both cold and hot arid and semi-arid deserts. It does not apply to ice capped or permafrost regions. It pertains to roughly 32 million square kilometres of land. Deserts span all seven continents of the Earth and make up nearly a fifth of the Earth's landmass, areas that recently have been increasing in size. As some of the deserts expand and global temperatures increase, the different methods of desert greening may provide a potential solution. Planting suitable flora in deserts has a range of environmental benefits from carbon sequestration to providing habitat for native desert fauna to generating employment opportunities to creation of habitable areas for local communities. The prevention of land desertification is one of 17 sustainable development objectives outlined by the United Nations, desert greening is a process that aims to not only combat desertification but to foster an environment where plants can create a sustainable environment for all forms of life while preserving its integrity.

An evaporator, distiller or distilling apparatus is a piece of ship's equipment used to produce fresh drinking water from sea water by distillation. As fresh water is bulky, may spoil in storage, and is an essential supply for any long voyage, the ability to produce more fresh water in mid-ocean is important for any ship.

Membrane distillation (MD) is a thermally driven separation process in which separation is driven by phase change. A hydrophobic membrane presents a barrier for the liquid phase, allowing the vapour phase to pass through the membrane's pores. The driving force of the process is a partial vapour pressure difference commonly triggered by a temperature difference.

A concentrated solar still is a system that uses the same quantity of solar heat input as a simple solar still but can produce a volume of freshwater that is many times greater. While a simple solar still is a way of distilling water by using the heat of the sun to drive evaporation from a water source and ambient air to cool a condenser film, a concentrated solar still uses a concentrated solar thermal collector to concentrate solar heat and deliver it to a multi-effect evaporation process for distillation, thus increasing the natural rate of evaporation. The concentrated solar still is capable of large-scale water production in areas with plentiful solar energy.

Sundrop Farms is a developer, owner and operator of high tech greenhouse facilities which grow crops using methods which reduce reliance on finite natural resources when compared to conventional greenhouse production. Sundrop Farms opened its first pilot facility in Port Augusta, South Australia, in 2010. This facility was originally designed as a Seawater Greenhouse. However, significant technology changes led to the Sundrop System, and the dissolution of the joint venture with Seawater Greenhouse Ltd. Sundrop Farms commissioned an expanded 20 ha facility south of Port Augusta in 2016. Sundrop Farms has offices in London, UK and Adelaide, Australia. In October 2016, Sundrop Farms was operating greenhouses in Portugal, the United States and had another facility planned in Australia.

The low-temperature distillation (LTD) technology is the first implementation of the direct spray distillation (DSD) process. The first large-scale units are now in operation for desalination. The process was first developed by scientists at the University of Applied Sciences in Switzerland, focusing on low-temperature distillation in vacuum conditions, from 2000 to 2005.

The IBTS greenhouse is a biotectural, urban development project suited for hot arid deserts. It was part of the Egyptian strategy for the afforestation of desert lands from 2011 until spring of 2015, when geopolitical changes like the Islamic State of Iraq and the Levant – Sinai Province in Egypt forced the project to a halt. The project begun in spring 2007 as an academic study in urban development and desert greening. It was further developed by N. Berdellé and D. Voelker as a private project until 2011. Afterwards LivingDesert Group including Prof. Abdel Ghany El Gindy and Dr. Mosaad Kotb from the Central Laboratory for Agricultural Climate in Egypt, Forestry Scientist Hany El-Kateb, Agroecologist Wil van Eijsden and permaculturist Sepp Holzer was created to introduce the finished project in Egypt.