Related Research Articles

Combustion, or burning, is a high-temperature exothermic redox chemical reaction between a fuel and an oxidant, usually atmospheric oxygen, that produces oxidized, often gaseous products, in a mixture termed as smoke. Combustion does not always result in fire, because a flame is only visible when substances undergoing combustion vaporize, but when it does, a flame is a characteristic indicator of the reaction. While the activation energy must be overcome to initiate combustion, the heat from a flame may provide enough energy to make the reaction self-sustaining.

Catalysis is the process of increasing the rate of a chemical reaction by adding a substance known as a catalyst. Catalysts are not consumed in the reaction and remain unchanged after it. If the reaction is rapid and the catalyst recycles quickly, very small amounts of catalyst often suffice; mixing, surface area, and temperature are important factors in reaction rate. Catalysts generally react with one or more reactants to form intermediates that subsequently give the final reaction product, in the process of regenerating the catalyst.

A chemical reaction is a process that leads to the chemical transformation of one set of chemical substances to another. Classically, chemical reactions encompass changes that only involve the positions of electrons in the forming and breaking of chemical bonds between atoms, with no change to the nuclei, and can often be described by a chemical equation. Nuclear chemistry is a sub-discipline of chemistry that involves the chemical reactions of unstable and radioactive elements where both electronic and nuclear changes can occur.

The following outline is provided as an overview of and topical guide to chemistry:

The Haber process, also called the Haber–Bosch process, is an artificial nitrogen fixation process and is the main industrial procedure for the production of ammonia today. It is named after its inventors, the German chemists Fritz Haber and Carl Bosch, who developed it in the first decade of the 20th century. The process converts atmospheric nitrogen (N2) to ammonia (NH3) by a reaction with hydrogen (H2) using a metal catalyst under high temperatures and pressures:

Solid-state chemistry, also sometimes referred as materials chemistry, is the study of the synthesis, structure, and properties of solid phase materials, particularly, but not necessarily exclusively of, non-molecular solids. It therefore has a strong overlap with solid-state physics, mineralogy, crystallography, ceramics, metallurgy, thermodynamics, materials science and electronics with a focus on the synthesis of novel materials and their characterisation. Solids can be classified as crystalline or amorphous on basis of the nature of order present in the arrangement of their constituent particles.

The reaction rate or rate of reaction is the speed at which a chemical reaction takes place, defined as proportional to the increase in the concentration of a product per unit time and to the decrease in the concentration of a reactant per unit time. Reaction rates can vary dramatically. For example, the oxidative rusting of iron under Earth's atmosphere is a slow reaction that can take many years, but the combustion of cellulose in a fire is a reaction that takes place in fractions of a second. For most reactions, the rate decreases as the reaction proceeds. A reaction's rate can be determined by measuring the changes in concentration over time.

Chemical kinetics, also known as reaction kinetics, is the branch of physical chemistry that is concerned with understanding the rates of chemical reactions. It is to be contrasted with chemical thermodynamics, which deals with the direction in which a reaction occurs but in itself tells nothing about its rate. Chemical kinetics includes investigations of how experimental conditions influence the speed of a chemical reaction and yield information about the reaction's mechanism and transition states, as well as the construction of mathematical models that also can describe the characteristics of a chemical reaction.

In thermochemistry, an exothermic reaction is a "reaction for which the overall standard enthalpy change ΔH⚬ is negative." Exothermic reactions usually release heat. The term is often confused with exergonic reaction, which IUPAC defines as "... a reaction for which the overall standard Gibbs energy change ΔG⚬ is negative." A strongly exothermic reaction will usually also be exergonic because ΔH⚬ makes a major contribution to ΔG⚬. Most of the spectacular chemical reactions that are demonstrated in classrooms are exothermic and exergonic. The opposite is an endothermic reaction, which usually takes up heat and is driven by an entropy increase in the system.

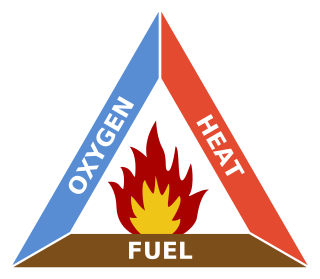

The fire triangle or combustion triangle is a simple model for understanding the necessary ingredients for most fires.

Titanium diboride (TiB2) is an extremely hard ceramic which has excellent heat conductivity, oxidation stability and wear resistance. TiB2 is also a reasonable electrical conductor, so it can be used as a cathode material in aluminium smelting and can be shaped by electrical discharge machining.

A chemical reactor is an enclosed volume in which a chemical reaction takes place. In chemical engineering, it is generally understood to be a process vessel used to carry out a chemical reaction, which is one of the classic unit operations in chemical process analysis. The design of a chemical reactor deals with multiple aspects of chemical engineering. Chemical engineers design reactors to maximize net present value for the given reaction. Designers ensure that the reaction proceeds with the highest efficiency towards the desired output product, producing the highest yield of product while requiring the least amount of money to purchase and operate. Normal operating expenses include energy input, energy removal, raw material costs, labor, etc. Energy changes can come in the form of heating or cooling, pumping to increase pressure, frictional pressure loss or agitation.

Thermogravimetric analysis or thermal gravimetric analysis (TGA) is a method of thermal analysis in which the mass of a sample is measured over time as the temperature changes. This measurement provides information about physical phenomena, such as phase transitions, absorption, adsorption and desorption; as well as chemical phenomena including chemisorptions, thermal decomposition, and solid-gas reactions.

In chemistry, heterogeneous catalysis is catalysis where the phase of catalysts differs from that of the reactants or products. The process contrasts with homogeneous catalysis where the reactants, products and catalyst exist in the same phase. Phase distinguishes between not only solid, liquid, and gas components, but also immiscible mixtures, or anywhere an interface is present.

Chemical beam epitaxy (CBE) forms an important class of deposition techniques for semiconductor layer systems, especially III-V semiconductor systems. This form of epitaxial growth is performed in an ultrahigh vacuum system. The reactants are in the form of molecular beams of reactive gases, typically as the hydride or a metalorganic. The term CBE is often used interchangeably with metal-organic molecular beam epitaxy (MOMBE). The nomenclature does differentiate between the two processes, however. When used in the strictest sense, CBE refers to the technique in which both components are obtained from gaseous sources, while MOMBE refers to the technique in which the group III component is obtained from a gaseous source and the group V component from a solid source.

A fluidized bed reactor (FBR) is a type of reactor device that can be used to carry out a variety of multiphase chemical reactions. In this type of reactor, a fluid is passed through a solid granular material at high enough speeds to suspend the solid and cause it to behave as though it were a fluid. This process, known as fluidization, imparts many important advantages to an FBR. As a result, FBRs are used for many industrial applications.

Zirconium diboride (ZrB2) is a highly covalent refractory ceramic material with a hexagonal crystal structure. ZrB2 is an ultra-high temperature ceramic (UHTC) with a melting point of 3246 °C. This along with its relatively low density of ~6.09 g/cm3 (measured density may be higher due to hafnium impurities) and good high temperature strength makes it a candidate for high temperature aerospace applications such as hypersonic flight or rocket propulsion systems. It is an unusual ceramic, having relatively high thermal and electrical conductivities, properties it shares with isostructural titanium diboride and hafnium diboride.

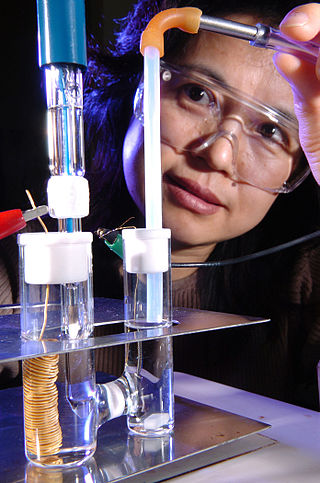

An electrocatalyst is a catalyst that participates in electrochemical reactions. Electrocatalysts are a specific form of catalysts that function at electrode surfaces or, most commonly, may be the electrode surface itself. An electrocatalyst can be heterogeneous such as a platinized electrode. Homogeneous electrocatalysts, which are soluble, assist in transferring electrons between the electrode and reactants, and/or facilitate an intermediate chemical transformation described by an overall half reaction. Major challenges in electrocatalysts focus on fuel cells.

Carbohydrides are solid compounds in one phase composed of a metal with carbon and hydrogen in the form of carbide and hydride ions. The term carbohydride can also refer to a hydrocarbon.

In chemistry, a hydridonitride is a chemical compound that contains hydride and nitride ions in a single phase. These inorganic compounds are distinct from inorganic amides and imides as the hydrogen does not share a bond with nitrogen, and contain a larger proportion of metals.

References

- ↑ "Concise Encyclopedia of Self-Propagating High-Temperature Synthesis. History, Theory, Technology, and Products". 1st Ed., Editors: I.Borovinskaya, A.Gromov, E.Levashov et al., Imprint: Elsevier Science, 2017

- ↑ Mukasyan, Alexander S.; Shuck, Christopher E.; Pauls, Joshua M; Manukyan, Khachatur V. (2018-12-02). "The Solid Flame Phenomenon: A Novel Perspective". Advanced Engineering Materials. 174 (2–3): 677–686. doi:10.1016/j.cej.2011.09.028.

- ↑ "Self-propagated high-temperature synthesis of refractory inorganic compounds", A.G. Merzhanov, I.P. Borovinskaya. Doklady Akademii Nauk SSSR, Vol. 204, N 2, pp. 366-369, May, 1972

- ↑ USSR Patent No. 255221, Byull. Izobr. No. 10

- ↑ Pini, Martina; Rosa, Roberto; Neri, Paolo; Bondioli, Federica; Ferrari, Anna Maria (2015). "Environmental assessment of a bottom-up hydrolytic synthesis of TiO nanoparticles". Green Chemistry. 17 (1): 518–531. doi:10.1039/C4GC00919C. hdl: 11380/1074899 .

- 1 2 Philippe R. Bonneau, John B. Wiley, Richard B. Kaner "Metathetical Precursor Route to Molybdenum Disulfide" Inorganic Syntheses 1995, vol. 30, pp. 33–37. doi : 10.1002/9780470132616.ch8

- ↑ Mukasyan, Alexander S.; Khina, Boris B.; Reeves, Robert V.; Son, Steven F. (2011-11-01). "Mechanical activation and gasless explosion: Nanostructural aspects". Chemical Engineering Journal. 174 (2–3): 677–686. doi:10.1016/j.cej.2011.09.028.

- ↑ Shuck, Christopher E.; Manukyan, Khachatur V.; Rouvimov, Sergei; Rogachev, Alexander S.; Mukasyan, Alexander S. (2016-01-01). "Solid-flame: Experimental validation". Combustion and Flame. 163: 487–493. doi: 10.1016/j.combustflame.2015.10.025 .

- ↑ Kurbatkina, Viktoria; Patsera, Evgeny; Levashov, Evgeny; Vorotilo, Stepan (2018). "SHS Processing and Consolidation of Ta–Ti–C, Ta–Zr–C, and Ta–Hf–C Carbides for Ultra‐High‐Temperatures Application". Advanced Engineering Materials. 20 (8): 1701065. doi: 10.1002/adem.201701065 .

- ↑ Richard G. Blair, Richard B. Kaner "Solid-State Metathesis Materials Synthesis" http://www.sigmaaldrich.com/sigma-aldrich/technical-documents/articles/chemfiles/solid-state-metathesis.html

- ↑ Yin, Xi; Chen, Kexin; Ning, Xiaoshan; Zhou, Heping (2010). "Combustion Synthesis of Ti3SiC2/TiC Composites from Elemental Powders under High-Gravity Conditions". Journal of the American Ceramic Society. 93 (8): 2182–2187. doi:10.1111/j.1551-2916.2010.03714.x.

- ↑ M.I. Ojovan, W.E. Lee. Self sustaining vitrification for immobilization of radioactive and toxic waste. Glass Technology, 44 (6) 218-224 (2003)

- ↑ Mukasyan, A. S.; Shuck, C. E. (23 September 2017). "Kinetics of SHS reactions: A review". International Journal of Self-Propagating High-Temperature Synthesis. 26 (3): 145–165. doi:10.3103/S1061386217030049. S2CID 139194446.

- ↑ Hunt, Emily M.; Pantoya, Michelle L. (August 2005). "Ignition dynamics and activation energies of metallic thermites: From nano- to micron-scale particulate composites". Journal of Applied Physics. 98 (3): 034909. doi:10.1063/1.1990265.

- ↑ Shuck, Christopher E.; Mukasyan, Alexander S. (February 2017). "Reactive Ni/Al Nanocomposites: Structural Characteristics and Activation Energy". The Journal of Physical Chemistry A. 121 (6): 1175–1181. doi:10.1021/acs.jpca.6b12314. PMID 28099018.

- ↑ Mukasyan, A.S.; White, J.D.E.; Kovalev, D.Y.; Kochetov, N.A.; Ponomarev, V.I.; Son, S.F. (January 2010). "Dynamics of phase transformation during thermal explosion in the Al–Ni system: Influence of mechanical activation". Physica B: Condensed Matter. 405 (2): 778–784. doi:10.1016/j.physb.2009.10.001.