Related Research Articles

The Occupational Safety and Health Administration is a large regulatory agency of the United States Department of Labor that originally had federal visitorial powers to inspect and examine workplaces. The United States Congress established the agency under the Occupational Safety and Health Act, which President Richard M. Nixon signed into law on December 29, 1970. OSHA's mission is to "assure safe and healthy working conditions for working men and women by setting and enforcing standards and by providing training, outreach, education, and assistance." The agency is also charged with enforcing a variety of whistleblower statutes and regulations. OSHA's workplace safety inspections have been shown to reduce injury rates and injury costs without adverse effects on employment, sales, credit ratings, or firm survival.

A datasheet, data sheet, or spec sheet is a document that summarizes the performance and other characteristics of a product, machine, component, material, subsystem, or software in sufficient detail that allows a buyer to understand what the product is and a design engineer to understand the role of the component in the overall system. Typically, a datasheet is created by the manufacturer and begins with an introductory page describing the rest of the document, followed by listings of specific characteristics, with further information on the connectivity of the devices. In cases where there is relevant source code to include, it is usually attached near the end of the document or separated into another file. Datasheets are created, stored, and distributed via product information management or product data management systems.

A safety data sheet (SDS), material safety data sheet (MSDS), or product safety data sheet (PSDS) is a document that lists information relating to occupational safety and health for the use of various substances and products. SDSs are a widely used system for cataloguing information on chemicals, chemical compounds, and chemical mixtures. SDS information may include instructions for the safe use and potential hazards associated with a particular material or product, along with spill-handling procedures. The older MSDS formats could vary from source to source within a country depending on national requirements; however, the newer SDS format is internationally standardized.

Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) is a European Union regulation dating from 18 December 2006. REACH addresses the production and use of chemical substances, and their potential impacts on both human health and the environment. Its 849 pages took seven years to pass, and it has been described as the most complex legislation in the Union's history and the most important in 20 years. It is the strictest law to date regulating chemical substances and will affect industries throughout the world. REACH entered into force on 1 June 2007, with a phased implementation over the next decade. The regulation also established the European Chemicals Agency, which manages the technical, scientific and administrative aspects of REACH.

The Toxic Substances Control Act (TSCA) is a United States law, passed by the 94th United States Congress in 1976 and administered by the United States Environmental Protection Agency (EPA), that regulates chemicals not regulated by other U.S. federal statutes, including chemicals already in commerce and the introduction of new chemicals. When the TSCA was put into place, all existing chemicals were considered to be safe for use and subsequently grandfathered in. Its three main objectives are to assess and regulate new commercial chemicals before they enter the market, to regulate chemicals already existing in 1976 that posed an "unreasonable risk of injury to health or the environment", as for example PCBs, lead, mercury and radon, and to regulate these chemicals' distribution and use.

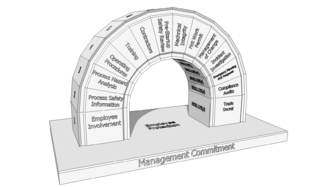

Process safety managementsystem is a regulation promulgated by the U.S. Occupational Safety and Health Administration (OSHA). A process is any activity or combination of activities including any use, storage, manufacturing, handling or the on-site movement of highly hazardous chemicals (HHCs) as defined by OSHA and the Environmental Protection Agency.

The Dangerous Substances Directive was one of the main European Union laws concerning chemical safety, until its full replacement by the new regulation CLP Regulation (2008), starting in 2016. It was made under Article 100 of the Treaty of Rome. By agreement, it is also applicable in the EEA, and compliance with the directive will ensure compliance with the relevant Swiss laws. The Directive ceased to be in force on 31 May 2015 and was repealed by Regulation (EC) No 1272/2008 of the European Parliament and of the Council of 16 December 2008 on classification, labelling and packaging of substances and mixtures, amending and repealing Directives 67/548/EEC and 1999/45/EC, and amending Regulation (EC) No 1907/2006.

A chemical accident is the unintentional release of one or more chemical hazard substances which could harm human health and the environment. Such events include fires, explosions, leakages or release of toxic or hazardous materials that can cause people illness, injury, or disability. Chemical accident can be caused by natural disaster, or accidental human error, or deliberate move to cause chaos and destructions for personal gain.

A hazard analysis is used as the first step in a process used to assess risk. The result of a hazard analysis is the identification of different types of hazards. A hazard is a potential condition and exists or not. It may, in single existence or in combination with other hazards and conditions, become an actual Functional Failure or Accident (Mishap). The way this exactly happens in one particular sequence is called a scenario. This scenario has a probability of occurrence. Often a system has many potential failure scenarios. It also is assigned a classification, based on the worst case severity of the end condition. Risk is the combination of probability and severity. Preliminary risk levels can be provided in the hazard analysis. The validation, more precise prediction (verification) and acceptance of risk is determined in the risk assessment (analysis). The main goal of both is to provide the best selection of means of controlling or eliminating the risk. The term is used in several engineering specialties, including avionics, chemical process safety, safety engineering, reliability engineering and food safety.

In the experimental (non-clinical) research arena, good laboratory practice or GLP is a quality system of management controls for research laboratories and organizations to ensure the uniformity, consistency, reliability, reproducibility, quality, and integrity of products in development for human or animal health through non-clinical safety tests; from physio-chemical properties through acute to chronic toxicity tests.

This page provides supplementary chemical data on sodium chloride.

International Chemical Safety Cards (ICSC) are data sheets intended to provide essential safety and health information on chemicals in a clear and concise way. The primary aim of the Cards is to promote the safe use of chemicals in the workplace and the main target users are therefore workers and those responsible for occupational safety and health. The ICSC project is a joint venture between the World Health Organization (WHO) and the International Labour Organization (ILO) with the cooperation of the European Commission (EC). This project began during the 1980s with the objective of developing a product to disseminate the appropriate hazard information on chemicals at the workplace in an understandable and precise way.

The Globally Harmonized System of Classification and Labelling of Chemicals (GHS) is an internationally agreed-upon standard managed by the United Nations that was set up to replace the assortment of hazardous material classification and labelling schemes previously used around the world. Core elements of the GHS include standardized hazard testing criteria, universal warning pictograms, and harmonized safety data sheets which provide users of dangerous goods with a host of information. The system acts as a complement to the UN Numbered system of regulated hazardous material transport. Implementation is managed through the UN Secretariat. Although adoption has taken time, as of 2017, the system has been enacted to significant extents in most major countries of the world. This includes the European Union, which has implemented the United Nations' GHS into EU law as the CLP Regulation, and United States Occupational Safety and Health Administration standards.

Food safety is used as a scientific method/discipline describing handling, preparation, and storage of food in ways that prevent food-borne illness. The occurrence of two or more cases of a similar illness resulting from the ingestion of a common food is known as a food-borne disease outbreak. This includes a number of routines that should be followed to avoid potential health hazards. In this way, food safety often overlaps with food defense to prevent harm to consumers. The tracks within this line of thought are safety between industry and the market and then between the market and the consumer. In considering industry to market practices, food safety considerations include the origins of food including the practices relating to food labeling, food hygiene, food additives and pesticide residues, as well as policies on biotechnology and food and guidelines for the management of governmental import and export inspection and certification systems for foods. In considering market to consumer practices, the usual thought is that food ought to be safe in the market and the concern is safe delivery and preparation of the food for the consumer. Food safety, nutrition and food security are closely related. Unhealthy food creates a cycle of disease and malnutrition that affects infants and adults as well.

Toy safety is the practice of ensuring that toys, especially those made for children, are safe, usually through the application of set safety standards. In many countries, commercial toys must be able to pass safety tests in order to be sold. In the U.S., some toys must meet national standards, while other toys may not have to meet a defined safety standard. In countries where standards exist, they exist in order to prevent accidents, but there have still been some high-profile product recalls after such problems have occurred. The danger is often not due to faulty design; usage and chance both play a role in injury and death incidents as well.

Right to know is a human right enshrined in law in several countries. UNESCO defines it as the right for people to "participate in an informed way in decisions that affect them, while also holding governments and others accountable". It pursues universal access to information as essential foundation of inclusive knowledge societies. It is often defined in the context of the right for people to know about their potential exposure to environmental conditions or substances that may cause illness or injury, but it can also refer more generally to freedom of information or informed consent.

A recommended exposure limit (REL) is an occupational exposure limit that has been recommended by the United States National Institute for Occupational Safety and Health. The REL is a level that NIOSH believes would be protective of worker safety and health over a working lifetime if used in combination with engineering and work practice controls, exposure and medical monitoring, posting and labeling of hazards, worker training and personal protective equipment. To formulate these recommendations, NIOSH evaluates all known and available medical, biological, engineering, chemical, trade, and other information. Although not legally enforceable limits, RELS are transmitted to the Occupational Safety and Health Administration (OSHA) or the Mine Safety and Health Administration (MSHA) of the U.S. Department of Labor for use in promulgating legal standards.

The Food Quality Protection Act (FQPA), or H.R.1627, was passed unanimously by Congress in 1996 and was signed into law by President Bill Clinton on August 3, 1996. The FQPA standardized the way the Environmental Protection Agency (EPA) would manage the use of pesticides and amended the Federal Insecticide, Fungicide, and Rodenticide Act and the Federal Food Drug and Cosmetic Act. It mandated a health-based standard for pesticides used in foods, provided special protections for babies and infants, streamlined the approval of safe pesticides, established incentives for the creation of safer pesticides, and required that pesticide registrations remain current.

Workplace health surveillance or occupational health surveillance (U.S.) is the ongoing systematic collection, analysis, and dissemination of exposure and health data on groups of workers. The Joint ILO/WHO Committee on Occupational Health at its 12th Session in 1995 defined an occupational health surveillance system as "a system which includes a functional capacity for data collection, analysis and dissemination linked to occupational health programmes".

Occupational safety and health (OSH), also commonly referred to as occupational health and safety (OHS), occupational health, or occupational safety, is a multidisciplinary field concerned with the safety, health, and welfare of people at work. These terms also refer to the goals of this field, so their use in the sense of this article was originally an abbreviation of occupational safety and health program/department etc.

References

- NIST Standard Reference Database

- David R. Lide, ed. Handbook of Chemistry and Physics, 85th Edition, Internet Version 2005. CRC Press, 2005.