Lean manufacturing is a production method aimed primarily at reducing times within the production system as well as response times from suppliers and to customers. It is closely related to another concept called just-in-time manufacturing. Just-in-time manufacturing tries to match production to demand by only supplying goods which have been ordered and focuses on efficiency, productivity, and reduction of "wastes" for the producer and supplier of goods. Lean manufacturing adopts the just-in-time approach and additionally focuses on reducing cycle, flow, and throughput times by further eliminating activities which do not add any value for the customer. Lean manufacturing also involves people who work outside of the manufacturing process, such as in marketing and customer service.

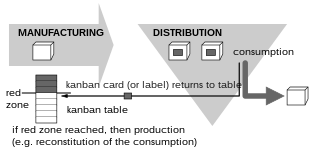

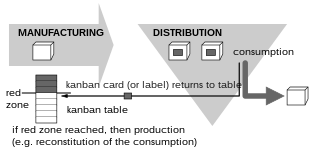

Kanban is a scheduling system for lean manufacturing. Taiichi Ohno, an industrial engineer at Toyota, developed kanban to improve manufacturing efficiency. The system takes its name from the cards that track production within a factory. Kanban is also known as the Toyota nameplate system in the automotive industry.

The Toyota Production System (TPS) is an integrated socio-technical system, developed by Toyota, that comprises its management philosophy and practices. The TPS is a management system that organizes manufacturing and logistics for the automobile manufacturer, including interaction with suppliers and customers. The system is a major precursor of the more generic "lean manufacturing". Taiichi Ohno and Eiji Toyoda, Japanese industrial engineers, developed the system between 1948 and 1975.

Poka-yoke is a Japanese term that means "mistake-proofing" or "error prevention". It is also sometimes referred to as a forcing function or a behavior-shaping constraint.

Operations management is concerned with designing and controlling the production of goods and services, ensuring that businesses are efficient in using resources to meet customer requirements.

In manufacturing, changeover is the process of converting a line or machine from running one product to another. Changeover times can last from a few minutes to as much as several weeks in the case of automobile manufacturers retooling for new models. Reducing changeover times became a popular way to reduce waste in Lean manufacturing after Taiichi Ohno and Shingo Shigeo popularized the SMED method in the, now famous, Toyota Production System (TPS). The terms set-up and changeover are sometimes used interchangeably however this usage is incorrect. Set-up is only one component of changeover. Example: A soft drink bottler may run 16oz glass bottles one day, perform a changeover on the line and then run 20oz plastic bottles the next day.

Shigeo Shingo was a Japanese industrial engineer who was considered as the world’s leading expert on manufacturing practices and the Toyota Production System.

Muda is a Japanese word meaning "futility", "uselessness", or "wastefulness", and is a key concept in lean process thinking such as in the Toyota Production System (TPS), denoting one of three types of deviation from optimal allocation of resources. The other types are known by the Japanese terms mura ("unevenness") and muri ("overload"). Waste in this context refers to the wasting of time or resources rather than wasteful by-products and should not be confused with Waste reduction.

Ohno Taiichi was a Japanese industrial engineer and businessman. He is considered to be the father of the Toyota Production System, which inspired Lean Manufacturing in the U.S. He devised the seven wastes as part of this system. He wrote several books about the system, including Toyota Production System: Beyond Large-Scale Production.

Takt time, or simply takt, is a manufacturing term to describe the required product assembly duration that is needed to match the demand. Often confused with cycle time, takt time is a tool used to design work and it measures the average time interval between the start of production of one unit and the start of production of the next unit when items are produced sequentially. For calculations, it is the time to produce parts divided by the number of parts demanded in that time interval. The takt time is based on customer demand; if a process or a production line are unable to produce at takt time, either demand leveling, additional resources, or process re-engineering is needed to ensure on-time delivery.

Autonomation describes a feature of machine design to effect the principle of jidoka (自働化)(じどうか jidouka), used in the Toyota Production System (TPS) and lean manufacturing. It may be described as "intelligent automation" or "automation with a human touch". This type of automation implements some supervisory functions rather than production functions. At Toyota, this usually means that if an abnormal situation arises, the machine stops and the worker will stop the production line. It is a quality control process that applies the following four principles:

- Detect the abnormality.

- Stop.

- Fix or correct the immediate condition.

- Investigate the root cause and install a countermeasure.

Value-stream mapping, also known as material- and information-flow mapping, is a lean-management method for analyzing the current state and designing a future state for the series of events that take a product or service from the beginning of the specific process until it reaches the customer. A value stream map is a visual tool that displays all critical steps in a specific process and easily quantifies the time and volume taken at each stage. Value stream maps show the flow of both materials and information as they progress through the process.

Norman Bodek was a teacher, consultant, author and publisher who published over 100 Japanese management books in English, including the works of Taiichi Ohno and Dr. Shigeo Shingo. He taught a course on "The Best of Japanese Management Practices" at Portland State University. Bodek created the Shingo Prize with Dr. Vern Beuhler at Utah State University. He was elected to Industry Week's Manufacturing Hall of Fame and founded Productivity Press. He was also the President of PCS Press. He died on December 9, 2020, at the age of 88.

Frequent deliveries are a largely ignored but powerful way of leveling apparent demand within a supply chain and thereby reducing Mura. What is perhaps not so obvious is that this will reduce inventory levels and thereby assist progress along the Lean journey at the same time. The historical focus upon carrying full loads, sometimes of only one product, reduces the unit cost of transport but has sometimes hidden the true costs associated with achieving those transport discounts. It is also possible to gain some of these benefits by 'faking' frequent deliveries at the supply site.

Lean dynamics is a business management practice that emphasizes the same primary outcome as lean manufacturing or lean production of eliminating wasteful expenditure of resources. However, it is distinguished by its different focus of creating a structure for accommodating the dynamic business conditions that cause these wastes to accumulate in the first place.

The following outline is provided as an overview of and topical guide to production:

The P-Course is a practical training program about Industrial Engineering implemented to teach the main techniques for industrial work improvement. Although especially aimed at applications in manufacturing, it can be useful also to transfer the core concepts of systematic improvement approach to people involved in operational activities in non-manufacturing businesses.

Agile construction is an integrated system of principles and methods, and a philosophy of doing business adapted to jobsites and overall project delivery in the construction industry. It is born from agile manufacturing and project management, which is mostly used in manufacturing production, automotive and software developing teams. It is the application of the Toyota Production System to the construction industry, with two parallel paths: Measuring and improving productivity, as well as segregating and externalizing work through prefabrication and supply chain management.

The visual workplace is a continuous improvement paradigm that is closely related to lean manufacturing, the Toyota Production System (TPS), and operational excellence yet offers its own comprehensive methodology that aims for significant financial and cultural improvement gains. Introduced by Gwendolyn Galsworth in her 1997 book Visual Systems, this system integrates and codifies the many iterations of visuality in the world of continuous improvement.

The industrialization of construction is the process through which construction aims to improve productivity through increased mechanization and automation. The process commonly involves modularization, prefabrication, preassembly, and mass production.