Traffic comprises pedestrians, vehicles, ridden or herded animals, trains, and other conveyances that use public ways (roads/sidewalks) for travel and transportation.

Lean manufacturing is a method of manufacturing goods aimed primarily at reducing times within the production system as well as response times from suppliers and customers. It is closely related to another concept called just-in-time manufacturing. Just-in-time manufacturing tries to match production to demand by only supplying goods that have been ordered and focus on efficiency, productivity, and reduction of "wastes" for the producer and supplier of goods. Lean manufacturing adopts the just-in-time approach and additionally focuses on reducing cycle, flow, and throughput times by further eliminating activities that do not add any value for the customer. Lean manufacturing also involves people who work outside of the manufacturing process, such as in marketing and customer service.

Cruise control is a system that automatically controls the speed of an automobile. The system is a servomechanism that takes over the car's throttle to maintain a steady speed set by the driver.

Scientific management is a theory of management that analyzes and synthesizes workflows. Its main objective is improving economic efficiency, especially labor productivity. It was one of the earliest attempts to apply science to the engineering of processes in management. Scientific management is sometimes known as Taylorism after its pioneer, Frederick Winslow Taylor.

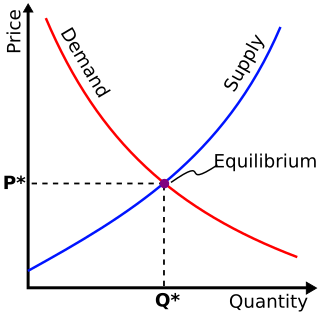

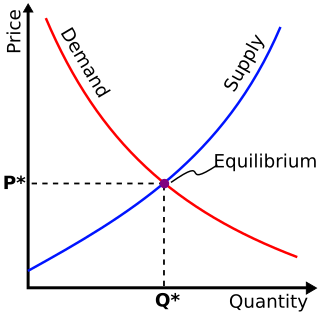

Productivity is the efficiency of production of goods or services expressed by some measure. Measurements of productivity are often expressed as a ratio of an aggregate output to a single input or an aggregate input used in a production process, i.e. output per unit of input, typically over a specific period of time. The most common example is the (aggregate) labour productivity measure, one example of which is GDP per worker. There are many different definitions of productivity and the choice among them depends on the purpose of the productivity measurement and data availability. The key source of difference between various productivity measures is also usually related to how the outputs and the inputs are aggregated to obtain such a ratio-type measure of productivity.

The term efficiency wages was introduced by Alfred Marshall to denote the wage per efficiency unit of labor. Marshallian efficiency wages are those calculated with efficiency or ability exerted being the unit of measure rather than time. That is, the more efficient worker will be paid more than a less efficient worker for the same amount of hours worked.

Industrial action or job action is a temporary show of dissatisfaction by employees—especially a strike or slowdown or working to rule—to protest against bad working conditions or low pay and to increase bargaining power with the employer and intended to force the employer to improve them by reducing productivity in a workplace. Industrial action is usually organized by trade unions or other organised labour, most commonly when employees are forced out of work due to contract termination and without reaching an agreement with the employer. Quite often it is used and interpreted as a euphemism for strike or mass strike, but the scope is much wider. Industrial action may take place in the context of a labour dispute or may be meant to effect political or social change. This form of communication tends to be their only means to voice their concerns about safety and benefits.

A man-hour or human-hour is the amount of work performed by the average worker in one hour. It is used for estimation of the total amount of uninterrupted labor required to perform a task. For example, researching and writing a college paper might require eighty man-hours, while preparing a family banquet from scratch might require ten man-hours.

Work-to-rule, also known as an Italian strike or a slowdown in United States usage, called in Italian a sciopero bianco meaning "white strike", is a job action in which employees do no more than the minimum required by the rules of their contract or job, and strictly follow time-consuming rules normally not enforced. This may cause a slowdown or decrease in productivity if the employer does not hire enough employees or pay the appropriate salary and consequently does not have the requirements needed to run normally.

Mechanised agriculture or agricultural mechanization is the use of machinery and equipment, ranging from simple and basic hand tools to more sophisticated, motorized equipment and machinery, to perform agricultural operations. In modern times, powered machinery has replaced many farm task formerly carried out by manual labour or by working animals such as oxen, horses and mules.

The Transport Workers' Union of Australia (TWU) is a trade union representing workers in various transport sectors. It has five main branches, covering the Australian Capital Territory/New South Wales, Queensland, Victoria/Tasmania, South Australia/Northern Territory, and Western Australia. The TWU's primary focus areas include road transport, commercial aviation, and more recently, gig economy workers.

Fleet management is the management of:

Overtime bans are a type of strike in which workers refuse to engage in overtime work, being any work that falls outside of contracted hours. They do this to leverage their employer into negotiating various working conditions. Often organised in unions, workers may choose this form of industrial action to bargain for a higher rate of pay, better working conditions or to discourage an employer from making redundancies. Unlike a full strike in which employees are usually in breach of their contract, workers engaging in overtime bans are typically well protected. Employers cannot legally withhold normal wages during an overtime ban if employees are not breaching the terms of their employment contracts by refusing to do overtime work. However, the legalities of overtime bans do vary between countries. Overtime bans are effective where "industries and organisations run on such habitually high levels of overtime or goodwill that overtime bans ... can have a significant and immediate impact upon the availability of a good or service". Historically, unions have at times received criticism on ethical grounds for choosing to enact overtime bans. The literature records the occurrence of such bans from the 1800s and there is documentation of their use in four continents.

Road traffic control involves directing vehicular and pedestrian traffic around a construction zone, accident or other road disruption, thus ensuring the safety of emergency response teams, construction workers and the general public.

Dynamic frequency scaling is a power management technique in computer architecture whereby the frequency of a microprocessor can be automatically adjusted "on the fly" depending on the actual needs, to conserve power and reduce the amount of heat generated by the chip. Dynamic frequency scaling helps preserve battery on mobile devices and decrease cooling cost and noise on quiet computing settings, or can be useful as a security measure for overheated systems.

Industrial engineering is an engineering profession that is concerned with the optimization of complex processes, systems, or organizations by developing, improving and implementing integrated systems of people, money, knowledge, information and equipment. Industrial engineering is central to manufacturing operations.

Ford Dagenham is a major automotive factory located in Dagenham, London, operated by the Ford of Britain subsidiary of Ford Motor Company. The plant opened in 1931 and has produced 10,980,368 cars and more than 39,000,000 engines in its history. It covers around 475 acres and has received over £800 million of capital investment since 2000.

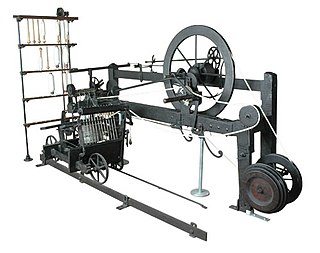

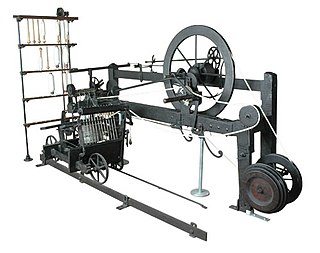

The productivity-improving technologies are the technological innovations that have historically increased productivity.

The 2011 Qantas industrial disputes were a series of disputes between the Australian airline Qantas and a number of trade unions during much of 2011 and the start of 2012. The disputes commenced in late 2010, when Qantas and unions commenced bargaining for new enterprise agreements. The bargaining became more heated when the airline announced its intentions to launch a new airline in Asia. During the bargaining, engineers, pilots and baggage handlers carried out a number of protected industrial actions, culminating in the decision by Qantas, on 29 October 2011, to lock out those employees. After an application by the Federal Minister for Workplace Relations, Fair Work Australia terminated the industrial action with effect from 2 am on 31 October 2011.