Stainless steel, also known as inox, corrosion-resistant steel (CRES) and rustless steel, is an alloy of iron that is resistant to rusting and corrosion. It contains iron with chromium and other elements such as molybdenum, carbon, nickel and nitrogen depending on its specific use and cost. Stainless steel's resistance to corrosion results from the 10.5%, or more, chromium content which forms a passive film that can protect the material and self-heal in the presence of oxygen.

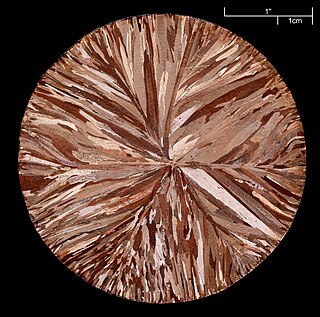

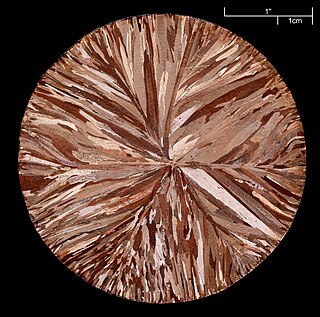

Hot-dip galvanization is a form of galvanization. It is the process of coating iron and steel with zinc, which alloys with the surface of the base metal when immersing the metal in a bath of molten zinc at a temperature of around 450 °C (842 °F). When exposed to the atmosphere, the pure zinc (Zn) reacts with oxygen (O2) to form zinc oxide (ZnO), which further reacts with carbon dioxide (CO2) to form zinc carbonate (ZnCO3), a usually dull grey, fairly strong material that protects the steel underneath from further corrosion in many circumstances. Galvanized steel is widely used in applications where corrosion resistance is needed without the cost of stainless steel, and is considered superior in terms of cost and life-cycle. It can be identified by the crystallization patterning on the surface (often called a "spangle").

Wüstite is a mineral form of mostly iron(II) oxide found with meteorites and native iron. It has a grey colour with a greenish tint in reflected light. Wüstite crystallizes in the isometric-hexoctahedral crystal system in opaque to translucent metallic grains. It has a Mohs hardness of 5 to 5.5 and a specific gravity of 5.88. Wüstite is a typical example of a non-stoichiometric compound.

Corrugated galvanised iron (CGI) or steel, colloquially corrugated iron, wriggly tin, pailing, corrugated sheet metal, zinc or custom orb / corro sheet (Australia) is a building material composed of sheets of hot-dip galvanised mild steel, cold-rolled to produce a linear ridged pattern in them. Although it is still popularly called "iron" in the UK, the material used is actually steel, and only the surviving vintage sheets may actually be made up of 100% iron. The corrugations increase the bending strength of the sheet in the direction perpendicular to the corrugations, but not parallel to them, because the steel must be stretched to bend perpendicular to the corrugations. Normally each sheet is manufactured longer in its strong direction.

A calender is a series of hard pressure rollers used to finish or smooth a sheet of material such as paper, textiles, rubber, or plastics. Calender rolls are also used to form some types of plastic films and to apply coatings. Some calender rolls are heated or cooled as needed. Calenders are sometimes misspelled calendars.

Sheet metal is metal formed into thin, flat pieces, usually by an industrial process.

Tinplate consists of sheets of steel coated with a thin layer of tin to impede rusting. Before the advent of cheap mild steel, the backing metal was wrought iron. While once more widely used, the primary use of tinplate now is the manufacture of tin cans.

Tinning is the process of thinly coating sheets of wrought iron or steel with tin, and the resulting product is known as tinplate. The term is also widely used for the different process of coating a metal with solder before soldering.

Pickling is a metal surface treatment used to remove impurities, such as stains, inorganic contaminants, and rust or scale from ferrous metals, copper, precious metals and aluminum alloys. A solution called pickle liquor, which usually contains acid, is used to remove the surface impurities. It is commonly used to descale or clean steel in various steelmaking processes.

Bluing, sometimes spelled as blueing, is a passivation process in which steel is partially protected against rust using a black oxide coating. It is named after the blue-black appearance of the resulting protective finish. Bluing involves an electrochemical conversion coating resulting from an oxidizing chemical reaction with iron on the surface selectively forming magnetite, the black oxide of iron. In comparison, rust, the red oxide of iron, undergoes an extremely large volume change upon hydration; as a result, the oxide easily flakes off, causing the typical reddish rusting away of iron. Black oxide provides minimal protection against corrosion, unless also treated with a water-displacing oil to reduce wetting and galvanic action. In colloquial use, thin coatings of black oxide are often termed 'gun bluing', while heavier coatings are termed 'black oxide'. Both refer to the same chemical process for providing true gun bluing.

Continuous casting, also called strand casting, is the process whereby molten metal is solidified into a "semifinished" billet, bloom, or slab for subsequent rolling in the finishing mills. Prior to the introduction of continuous casting in the 1950s, steel was poured into stationary molds to form ingots. Since then, "continuous casting" has evolved to achieve improved yield, quality, productivity and cost efficiency. It allows lower-cost production of metal sections with better quality, due to the inherently lower costs of continuous, standardised production of a product, as well as providing increased control over the process through automation. This process is used most frequently to cast steel. Aluminium and copper are also continuously cast.

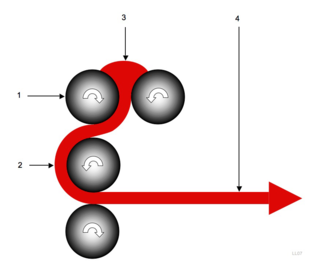

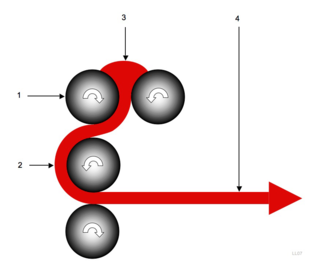

In metalworking, rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness, to make the thickness uniform, and/or to impart a desired mechanical property. The concept is similar to the rolling of dough. Rolling is classified according to the temperature of the metal rolled. If the temperature of the metal is above its recrystallization temperature, then the process is known as hot rolling. If the temperature of the metal is below its recrystallization temperature, the process is known as cold rolling. In terms of usage, hot rolling processes more tonnage than any other manufacturing process, and cold rolling processes the most tonnage out of all cold working processes. Roll stands holding pairs of rolls are grouped together into rolling mills that can quickly process metal, typically steel, into products such as structural steel, bar stock, and rails. Most steel mills have rolling mill divisions that convert the semi-finished casting products into finished products.

Parts cleaning is a step in various industrial processes, either as preparation for surface finishing or to safeguard delicate components. One such process, electroplating, is particularly sensitive to part cleanliness, as even thin layers of oil can hinder coating adhesion.

Sheet metal embossing is a stamping process for producing raised or sunken designs or relief in sheet metal. This process can be made by means of matched male and female roller dies, or by passing sheet or a strip of metal between rolls of the desired pattern. It is often combined with foil stamping to create a shiny, 3D effect.

Eco pickled surface (EPS) is a process applied to hot rolled sheet steel to remove all surface oxides and clean the steel surface. Steel which has undergone the EPS process acquires a high degree of resistance to subsequent development of surface oxide (rust), so long as it does not come into direct contact with moisture. EPS was developed by The Material Works, Ltd., which has filed several patent applications covering the process. It is primarily intended to be a replacement of the acid pickling process wherein steel strip is immersed in solutions of hydrochloric and sulfuric acids to chemically remove oxides.

Mill scale, often shortened to just scale, is the flaky surface of hot rolled steel, consisting of the mixed iron oxides iron(II) oxide, iron(III) oxide, and iron(II,III) oxide.

Strip steel or cold rolled strip is a steel product that is produced from a hot rolled strip that has been pickled. The coil is then reduced by a single stand cold roll steel mill straight away or reversing mill or in a tandem mill consisting of several single stands in a series. The strip is reduced to approximately final thickness by cold-rolling directly, or with the inclusion of an annealing operation at some intermediate thickness to facilitate further cold reduction or to obtain mechanical properties desired in the finished product. High carbon strip steel requires additional annealing and cold reduction operations. The coil is then slit to the desired width through the process of roll slitting. Stainless steel strip is the extension product of strip steel, usually long and narrow stainless steel strips are manufactured to meet the demands of various industrial and mechanical areas. According to the processing method, the stainless steel strip can be divided into cold rolled stainless steel strip and hot rolled stainless steel strip.

Seasoning is the process of coating the surface of cookware with fat which is heated in order to produce a corrosion resistant layer of polymerized fat. It is required for raw cast-iron cookware and carbon steel, which otherwise rust rapidly in use, but is also used for many other types of cookware. An advantage of seasoning is that it helps prevent food sticking.

Metal spinning, also known as spin forming or spinning or metal turning most commonly, is a metalworking process by which a disc or tube of metal is rotated at high speed and formed into an axially symmetric part. Spinning can be performed by hand or by a CNC lathe.

According to EN 13523-0, a prepainted metal is a ‘metal on which a coating material has been applied by coil coating’. When applied onto the metallic substrate, the coating material forms a film possessing protective, decorative and/or other specific properties.