Related Research Articles

A primary mirror is the principal light-gathering surface of a reflecting telescope.

A Ritchey–Chrétien telescope is a specialized variant of the Cassegrain telescope that has a hyperbolic primary mirror and a hyperbolic secondary mirror designed to eliminate off-axis optical errors (coma). The RCT has a wider field of view free of optical errors compared to a more traditional reflecting telescope configuration. Since the mid 20th century, a majority of large professional research telescopes have been Ritchey–Chrétien configurations; some well-known examples are the Hubble Space Telescope, the Keck telescopes and the ESO Very Large Telescope.

A reflecting telescope is a telescope that uses a single or a combination of curved mirrors that reflect light and form an image. The reflecting telescope was invented in the 17th century by Isaac Newton as an alternative to the refracting telescope which, at that time, was a design that suffered from severe chromatic aberration. Although reflecting telescopes produce other types of optical aberrations, it is a design that allows for very large diameter objectives. Almost all of the major telescopes used in astronomy research are reflectors. Reflecting telescopes come in many design variations and may employ extra optical elements to improve image quality or place the image in a mechanically advantageous position. Since reflecting telescopes use mirrors, the design is sometimes referred to as a catoptric telescope.

A rotating furnace is a device for making solid objects which have concave surfaces that are segments of axially symmetrical paraboloids. Usually, the objects are made of glass. The furnace makes use of the fact, which was known already to Newton, that the centrifugal-force-induced shape of the top surface of a spinning liquid is a concave paraboloid, identical to the shape of a reflecting telescope's primary focusing mirror.

Fused quartz,fused silica or quartz glass is glass consisting of silica in amorphous (non-crystalline) form. It differs from traditional glasses in containing no other ingredients, which are typically added to glass to lower the melt temperature. Fused silica, therefore, has high working and melting temperatures. Although the terms fused quartz and fused silica are used interchangeably, the optical and thermal properties of fused silica are superior to those of fused quartz and other types of glass due to its purity. For these reasons, it finds use in situations such as semiconductor fabrication and laboratory equipment. It transmits ultraviolet better than other glasses, so is used to make lenses and optics for the ultraviolet spectrum. The low coefficient of thermal expansion of fused quartz makes it a useful material for precision mirror substrates.

Speculum metal is a mixture of around two-thirds copper and one-third tin, making a white brittle alloy that can be polished to make a highly reflective surface. It was used historically to make different kinds of mirrors from personal grooming aids to optical devices until it was replaced by more modern materials such as metal-coated glass mirrors.

The Hale Telescope is a 200-inch (5.1 m), f/3.3 reflecting telescope at the Palomar Observatory in San Diego County, California, US, named after astronomer George Ellery Hale. With funding from the Rockefeller Foundation in 1928, he orchestrated the planning, design, and construction of the observatory, but with the project ending up taking 20 years he did not live to see its commissioning. The Hale was groundbreaking for its time, with double the diameter of the second-largest telescope, and pioneered many new technologies in telescope mount design and in the design and fabrication of its large aluminum coated "honeycomb" low thermal expansion Pyrex mirror. It was completed in 1949 and is still in active use.

The Giant Magellan Telescope (GMT) is a ground-based extremely large telescope under construction. It will consist of seven 8.4 m (27.6 ft) diameter primary segments, that will observe optical and near infrared (320–25000 nm) light, with the resolving power of a 24.5 m (80.4 ft) primary mirror and collecting area equivalent to a 22.0 m (72.2 ft) one, which is about 368 square meters. The telescope is expected to have a resolving power 10 times greater than the Hubble Space Telescope. As of November 2017, five mirrors had been cast and the construction of the summit facility has begun.

Borosilicate glass is a type of glass with silica and boron trioxide as the main glass-forming constituents. Borosilicate glasses are known for having very low coefficients of thermal expansion, making them more resistant to thermal shock than any other common glass. Such glass is subjected to less thermal stress and can withstand temperature differentials without fracturing of about 165 °C (297 °F). It is commonly used for the construction of reagent bottles and flasks as well as lighting, electronics and cookware.

Schott AG is a German multinational glass company specializing in the manufacture of glass and glass-ceramics. Headquartered in Mainz, Germany, it is owned by the Carl Zeiss Foundation. The company's founder and namesake, Otto Schott, is credited with the invention of borosilicate glass.

The 1.8 meter Alice P. Lennon Telescope and its Thomas J. Bannan Astrophysics Facility, known together as the Vatican Advanced Technology Telescope (VATT), is a Gregorian telescope observing in the optical and infrared situated on Mount Graham in southeast Arizona, United States. It achieved its first light in 1993.

Centrifugal casting in silversmithing is a casting technique where a small mould is poured, then spun on the end of an arm. The centrifugal force thus generated encourages a successful pour.

The MMT Observatory (MMTO) is an astronomical observatory on the site of Fred Lawrence Whipple Observatory. The Whipple observatory complex is located on Mount Hopkins, Arizona, US in the Santa Rita Mountains. The observatory is operated by the University of Arizona and the Smithsonian Institution, and has a visitor center in nearby Amado, Arizona. The MMTO is the home of the MMT, which has a primary mirror 6.5 m in diameter. The name comes from the six smaller mirrors originally used before the single primary mirror was installed in 1998. The primary mirror has a special lightweight honeycomb design made by the University of Arizona's Steward Observatory Mirror Laboratory. The MMT is housed in a building which allows the walls and roof around the telescope to be completely rolled back, allowing it to cool down very quickly in order to improve observation.

Liquid-mirror telescopes are telescopes with mirrors made with a reflective liquid. The most common liquid used is mercury, but other liquids will work as well. The liquid and its container are rotated at a constant speed around a vertical axis, which causes the surface of the liquid to assume a paraboloidal shape. This parabolic reflector can serve as the primary mirror of a reflecting telescope. The rotating liquid assumes the same surface shape regardless of the container's shape; to reduce the amount of liquid metal needed, and thus weight, a rotating mercury mirror uses a container that is as close to the necessary parabolic shape as possible. Liquid mirrors can be a low-cost alternative to conventional large telescopes. Compared to a solid glass mirror that must be cast, ground, and polished, a rotating liquid-metal mirror is much less expensive to manufacture.

A telescope is an optical instrument using lenses, curved mirrors, or a combination of both to observe distant objects, or various devices used to observe distant objects by their emission, absorption, or reflection of electromagnetic radiation. The first known practical telescopes were refracting telescopes invented in the Netherlands at the beginning of the 17th century, by using glass lenses. They were used for both terrestrial applications and astronomy.

A space telescope mirror is a concept for a type of reflecting space telescope that uses a reflecting liquid such as mercury as its primary reflector.

Ohara Inc. is a Japanese global glass manufacturing company. The company is headquartered in Sagamihara with subsidiaries in a number of countries, including Japan, the United States, Germany, Hong Kong, Malaysia, Taiwan, and China, with Ohara Corporation being the U.S. subsidiary of the Ohara Group. Ohara manufactures glasses since 1935, the year of its founding.

Centrifugal casting or rotocasting is a casting technique that is typically used to cast thin-walled cylinders. It is typically used to cast materials such as metals, glass, and concrete. A high quality is attainable by control of metallurgy and crystal structure. Unlike most other casting techniques, centrifugal casting is chiefly used to manufacture rotationally symmetric stock materials in standard sizes for further machining, rather than shaped parts tailored to a particular end-use.

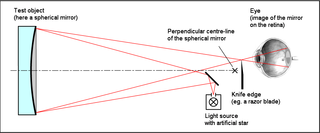

The Foucault knife-edge test is an optical test developed 150 years ago to accurately measure the shape of concave curved mirrors. It is commonly used by amateur telescope makers for figuring primary mirrors in reflecting telescopes. It uses a relatively simple, inexpensive apparatus compared to other testing techniques.

References

- ↑ "Optical Fabrication in the Large" (PDF). p. 6.