Vehicle dynamics is the study of vehicle motion, e.g., how a vehicle's forward movement changes in response to driver inputs, propulsion system outputs, ambient conditions, air/surface/water conditions, etc. Vehicle dynamics is a part of engineering primarily based on classical mechanics. It may be applied for motorized vehicles, bicycles and motorcycles, aircraft, and watercraft.

The unsprung mass of a vehicle is the mass of the suspension, wheels or tracks, and other components directly connected to them. This contrasts with the sprung mass supported by the suspension, which includes the body and other components within or attached to it. Components of the unsprung mass include the wheel axles, wheel bearings, wheel hubs, tires, and a portion of the weight of driveshafts, springs, shock absorbers, and suspension links. Brakes that are mounted inboard are part of a vehicle's sprung mass.

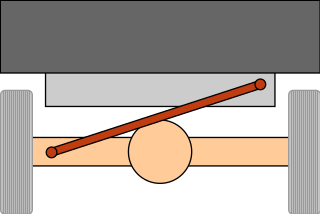

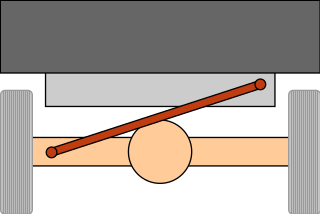

A Panhard rod is a suspension link that provides lateral location of the axle. Originally invented by the Panhard automobile company of France in the early twentieth century, this device has been widely used ever since.

Suspension is the system of tires, tire air, springs, shock absorbers and linkages that connects a vehicle to its wheels and allows relative motion between the two. Suspension systems must support both road holding/handling and ride quality, which are at odds with each other. The tuning of suspensions involves finding the right compromise. It is important for the suspension to keep the road wheel in contact with the road surface as much as possible, because all the road or ground forces acting on the vehicle do so through the contact patches of the tires. The suspension also protects the vehicle itself and any cargo or luggage from damage and wear. The design of front and rear suspension of a car may be different.

Independent suspension is any automobile suspension system that allows each wheel on the same axle to move vertically independently of the others. This is contrasted with a beam axle or deDion axle system in which the wheels are linked. "Independent" refers to the motion or path of movement of the wheels or suspension. It is common for the left and right sides of the suspension to be connected with anti-roll bars or other such mechanisms. The anti-roll bar ties the left and right suspension spring rates together but does not tie their motion together.

Automobile handling and vehicle handling are descriptions of the way a wheeled vehicle responds and reacts to the inputs of a driver, as well as how it moves along a track or road. It is commonly judged by how a vehicle performs particularly during cornering, acceleration, and braking as well as on the vehicle's directional stability when moving in steady state condition.

Car tuning is the modification of a car to optimise it for a different set of performance requirements from those it was originally designed to meet. Most commonly this is higher engine performance and dynamic handling characteristics but cars may also be altered to provide better fuel economy, or smoother response. The goal when tuning is the improvement of a vehicle's overall performance in response to the user's needs. Often, tuning is done at the expense of emissions performance, component reliability and occupant comfort.

Weight transfer and load transfer are two expressions used somewhat confusingly to describe two distinct effects:

A de Dion axle is a form of non-independent automobile suspension. It is a considerable improvement over the swing axle, Hotchkiss drive, or live axle. Because it plays no part in transmitting power to the drive wheels, it is sometimes called a "dead axle".

An inboard brake is an automobile technology wherein the disc brakes are mounted on the chassis of the vehicle, rather than directly on the wheel hubs. Its main advantages are twofold: a reduction in the unsprung weight of the wheel hubs, as this no longer includes the brake discs and calipers; and braking torque is applied directly to the chassis, rather than being transferred to it through the suspension arms.

An anti-roll bar is an automobile suspension part that helps reduce the body roll of a vehicle during fast cornering or over road irregularities. It links opposite front or rear wheels to a torsion spring using short lever arms for anchors. This increases the suspension's roll stiffness—its resistance to roll in turns.

Body roll is the axial rotation of a vehicle’s body towards the outside of a turn. Body roll occurs because the compliance in vehicle suspension allows the vehicle body, which sits upon the suspension, to lean in the direction of the perceived centrifugal force acting upon the vehicle.

A beam axle, rigid axle, or solid axle is a dependent suspension design in which a set of wheels is connected laterally by a single beam or shaft. Beam axles were once commonly used at the rear wheels of a vehicle, but historically, they have also been used as front axles in four-wheel-drive vehicles. In most automobiles, beam axles have been replaced with front (IFS) and rear independent suspensions (IRS).

An articulated hauler, articulated dump truck (ADT), or sometimes a dump hauler, is a very large heavy-duty type of dump truck used to transport loads over rough terrain, and occasionally on public roads. The vehicle usually has all-wheel drive and consists of two basic units: the front section, generally called the tractor, and the rear section that contains the dump body, called the hauler or trailer section. Steering is made by pivoting the front in relation to the back by hydraulic rams. This way, all wheels follow the same path, making it an excellent off-road vehicle.

The 7 post shaker is a piece of test equipment used to perform technical analysis on race cars. By applying shaking forces the shaker can emulate banking loads, lateral load transfer, longitudinal weight transfer and ride height sensitive downforce to emulate specific racetracks.

An exoskeleton car has a visible external frame, being made of steel, aluminum or carbon fiber tubes.

Jaguar's independent rear suspension (IRS) unit has been a common component of a number of Jaguar production cars since 1961, passing through two major changes of configuration up to 2006 and last used in the Jaguar XK8 and Aston Martin DB7. This article concentrates on the first generation Jaguar IRS, which firmly established the marque's reputation for suspension sophistication, combining as it did smooth ride with excellent roadholding and low levels of noise, vibration, and harshness (NVH). The two generations overlap in time due to their being used in both full size and sports models that were updated at different times.

A wheel hub motor, hub motor, or in-wheel motor is a motor that is incorporated into the hub of the wheel. Wheel-hub motors are commonly found on electric bicycles. Electric hub motors were well-received in early electric cars, but have not been commercially successful in modern production cars because they negatively affect vehicle handling due to higher dynamic wheel load and their placement makes them prone to damage.

Protean Electric is an automotive technology company specializing in in-wheel motor technology. The company has developed an in-wheel, electric-drive system for hybrid, plug-in hybrid, and battery electric vehicles. Their technology creates a permanent magnet e-machine with relatively high torque and power density with the power electronics and controls packaged within the motor itself. Their in-wheel motor product is intended to be produced in low volume by Protean Electric and licensed in high volume to global automotive and Tier 1 automotive supply companies. Protean Electric is a privately held company with approximately 114 employees. Protean Electric has operations in the United States, United Kingdom, and China.

Dubonnet suspension was a system of leading arm independent front suspension and steering popular mainly in the 1930s and 1940s. Not very durable unless exactingly maintained, it was soon replaced by other designs.