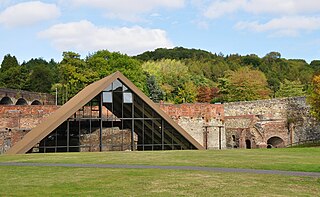

The Tobiashammer is a large, water-driven hammer mill in Ohrdruf in the German state of Thuringia. The mill, which dates to 1482, has been an industrial monument and museum since 1983.

The Tobiashammer is a large, water-driven hammer mill in Ohrdruf in the German state of Thuringia. The mill, which dates to 1482, has been an industrial monument and museum since 1983.

The first hammer forge was probably built in 1482 [1] on the River Ohra. In 1592 the mill was bought by Tobias Albrecht, since when it has been named after him. The works originally had three huge iron hammers which were raised by the motion of a water wheel.

The mill made iron products such as scythes, sickles, ploughshares, lances and swords. Later, it also carried out copper processing; washbowls, washtubs, kettle drums, brewing implements, pots, cans and pans were made. The kettle drums, which were produced into the late 20th century, were made from a single piece of copper, forged under the tilt hammer and still set a standard today in terms of their sound.

The Tobiashammer was owned by the Albrecht family until 1816 when they sold it. Thereafter its owners changed more often. From the mid-19th century the mill was significantly enlarged. A rolling mill and a second hammer mill was built. The office (Kontorhaus), built in 1882, now acts as a restaurant, the Hammerschenke.

In 1972 the old, ruined hammer mill was bought from private owners by the Ohrdruf Steelworks.

In 1983 the Tobiashammer was opened to the public as a demonstration mill.

The museum has five working trip hammers, a rolling mill, stamp mill and grinding workshop as well as furnaces. The mill is still driven by four water wheels.

Since 1988 the Tobiashammer has also housed one of the largest steam engines in Europe: a twin, tandem, reversing, steam engine, built in 1920, with a total weight of 305 tonnes and a power output of 12,000 horsepower. It comes from the old Maxhütte smeltery at Unterwellenborn and was decommissioned in 1985. The engine is fully working and is operated during guided tours.

An annual event that has taken place since the museum's opening in 1983 is the Blacksmiths’ Symposium (Schmiede-Symposium). In 2009 it was entitled "Tribute to Fritz Kühn" and brought together ornamental metalsmiths from three continents. Over the years many well-known metalsmiths and metal sculptors have created their works of art here. Many still grace the outer areas of the museum site as part of its sculpture park, such as the gigantic, forged water lily by Alfred Habermann and Das Gesicht by Rüdiger Roehl.

Metalworking is the process of shaping and reshaping metals to create useful objects, parts, assemblies, and large scale structures. As a term it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale: from huge ships, buildings, and bridges down to precise engine parts and delicate jewelry.

John "Iron-Mad" Wilkinson was an English industrialist who pioneered the manufacture of cast iron and the use of cast-iron goods during the Industrial Revolution. He was the inventor of a precision boring machine that could bore cast iron cylinders, such as cannon barrels and piston cylinders used in the steam engines of James Watt. His boring machine has been called the first machine tool. He also developed a blowing device for blast furnaces that allowed higher temperatures, increasing their efficiency, and helped sponsor the first iron bridge in Coalbrookdale. He is notable for his method of cannon boring, his techniques at casting iron, and his work with the government of France to establish a cannon foundry.

Coalbrookdale is a village in the Ironbridge Gorge in Shropshire, England, containing a settlement of great significance in the history of iron ore smelting. It lies within the civil parish called the Gorge.

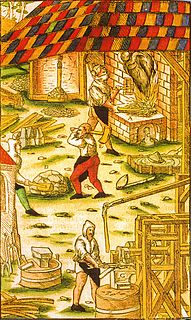

A trip hammer, also known as a tilt hammer or helve hammer, is a massive powered hammer. Traditional uses of trip hammers include pounding, decorticating and polishing of grain in agriculture. In mining, trip hammers were used for crushing metal ores into small pieces, although a stamp mill was more usual for this. In finery forges they were used for drawing out blooms made from wrought iron into more workable bar iron. They were also used for fabricating various articles of wrought iron, latten, steel and other metals.

A metalsmith or simply smith is a craftsperson fashioning useful items out of various metals. Smithing is one of the oldest metalworking occupations. Shaping metal with a hammer (forging) is the archetypical component of smithing. Often the hammering is done while the metal is hot, having been heated in a forge. Smithing can also involve the other aspects of metalworking, such as refining metals from their ores, casting it into shapes (founding), and filing to shape and size.

A hammer mill, hammer forge or hammer works was a workshop in the pre-industrial era that was typically used to manufacture semi-finished, wrought iron products or, sometimes, finished agricultural or mining tools, or military weapons. The feature that gave its name to these workshops was the water-driven trip hammer, or set of hammers, used in the process. The shaft, or 'helve', of the hammer was pivoted in the middle and the hammer head was lifted by the action of cams set on a rotating camshaft that periodically depressed the end of the shaft. As it rose and fell, the head of the hammer described an arc. The face of the hammer was made of iron for durability.

Haigh Foundry was an ironworks and foundry in Haigh, Lancashire, which was notable for the manufacture of early steam locomotives.

A stamp mill is a type of mill machine that crushes material by pounding rather than grinding, either for further processing or for extraction of metallic ores. Breaking material down is a type of unit operation.

The Leeds Industrial Museum at Armley Mills is a museum of industrial heritage located in Armley, near Leeds, in West Yorkshire, Northern England. The museum includes collections of textile machinery, railway equipment and heavy engineering amongst others.

Russian tableware plant Kolchug-Mizar is the largest manufacturer of tableware, plate and cutlery in Russia. It was founded in 1871. The plant is situated not far from Moscow. Kolchugino plant is well-known most because of popular kolchugino tea glass-holders or podstakanniks.

The Medway and its tributaries and sub-tributaries have been used for over 1,150 years as a source of power. There are over two hundred sites where the use of water power is known. These uses included corn milling, fulling, paper making, iron smelting, pumping water, making gunpowder, vegetable oil extraction, and electricity generation. Today, there is just one watermill working for trade. Those that remain have mostly been converted. Such conversions include a garage, dwellings, restaurants, museums and a wedding venue. Some watermills are mere derelict shells, lower walls or lesser remains. Of the majority, there is nothing to be seen. A large number of tributaries feed into the River Medway. The tributaries that powered watermills will be described in the order that they feed in. The mills are described in order from source to mouth. Left bank and right bank are referred to as though the reader is facing downstream. This article covers the watermills on the tributaries that feed in below Penshurst and above Yalding.

A steam hammer, also called a drop hammer, is an industrial power hammer driven by steam that is used for tasks such as shaping forgings and driving piles. Typically the hammer is attached to a piston that slides within a fixed cylinder, but in some designs the hammer is attached to a cylinder that slides along a fixed piston.

Little Matlock Rolling Mill also known as Low Matlock Rolling Mill is a Grade II* Listed building situated on the River Loxley in the village of Loxley on the outskirts of the City of Sheffield, South Yorkshire, England. The building continues to operate as a rolling mill, owned and operated by Pro-Roll Ltd, a specialist hand rolling company. A brick building extension was added to the original 1882 structure in 1939.

The Frohnauer Hammer is an historic hammer mill in Frohnau, a village in the municipality of Annaberg-Buchholz in the Ore Mountains of southeast Germany. The mill is an important witness to proto-industrial development in the Ore Mountains. Of the once-numerous hammer mills only three others remain working in Saxony: the Dorfchemnitz Iron Hammer Mill, the Grünthal Copper Hammer Mill and the Freibergsdorf Hammer Mill.

Eisenhammer Dorfchemnitz is an historic hammer mill in Dorfchemnitz in the Ore Mountains of Germany. The mill is an important witness to proto-industrial development in the Ore Mountains. Of the once-numerous hammer mills only three others remain working in Saxony apart from the Frohnauer Hammer: the Frohnauer Hammer Mill, the Grünthal Copper Hammer Mill and the Freibergsdorf Hammer Mill.

A water-returning engine was an early form of stationary steam engine, developed at the start of the Industrial Revolution in the middle of the 18th century. The first beam engines did not generate power by rotating a shaft but were developed as water pumps, mostly for draining mines. By coupling this pump with a water wheel, they could be used to drive machinery.

Thomas Walmsley and Sons was a company that manufactured wrought iron. It was founded in 1866 or 1869 by Thomas Walmsley at the Atlas Forge on a site bounded by Bridgeman Street and Fletcher Street in Bolton, then in Lancashire, England. The forge had at least 16 puddling furnaces and forging and rolling mills.

François Prudent Bourdon was a French engineer and inventor, mainly interested in development of steam-powered boats for inland navigation. He is known for designing one of the first steam hammers.

The Low Moor Ironworks was a wrought iron foundry established in 1791 in the village of Low Moor about 3 miles (4.8 km) south of Bradford in Yorkshire, England. The works were built to exploit the high-quality iron ore and low-sulphur coal found in the area. Low Moor made wrought iron products from 1801 until 1957 for export around the world. At one time it was the largest ironworks in Yorkshire, a major complex of mines, piles of coal and ore, kilns, blast furnaces, forges and slag heaps connected by railway lines. The surrounding countryside was littered with waste, and smoke from the furnaces and machinery blackened the sky. Today Low Moor is still industrial, but the pollution has been mostly eliminated.

Klaus Rudolf Werhand was a metalsmith and a coppersmith from Neuwied, Rhineland-Palatinate, Germany.

| Wikimedia Commons has media related to Tobiashammer . |

Coordinates: 50°48′07″N10°43′54″E / 50.801873°N 10.731776°E