Beer is one of the oldest alcoholic drinks in the world, the most widely consumed, and the third most popular drink after water and tea. Beer is produced by the brewing and fermentation of starches from cereal grains—most commonly malted barley, although wheat, maize (corn), rice, and oats are also used. The fermentation of the starch sugars in the wort produces ethanol and carbonation in the beer. Most modern beer is brewed with hops, which add bitterness and other flavours and act as a natural preservative and stabilising agent. Other flavouring agents, such as gruit, herbs, or fruits, may be included or used instead of hops. In commercial brewing, natural carbonation is often replaced with forced carbonation.

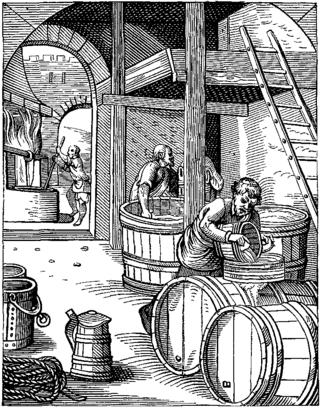

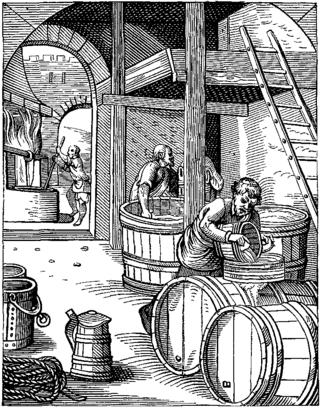

Brewing is the production of beer by steeping a starch source in water and fermenting the resulting sweet liquid with yeast. It may be done in a brewery by a commercial brewer, at home by a homebrewer, or communally. Brewing has taken place since around the 6th millennium BC, and archaeological evidence suggests that emerging civilizations, including ancient Egypt, China, and Mesopotamia, brewed beer. Since the nineteenth century the brewing industry has been part of most western economies.

Shepherd Neame is an English independent brewery which has been based in the market town of Faversham, Kent, for over 300 years. While 1698 is the brewery's official established date, town records show that commercial brewing has occurred on the site since 1573. Since the brewery's formation in the 16th century, ownership has passed in unbroken succession through five families. The brewery produces a range of cask ales and filtered beers. Production is around 180,000 brewers' barrels a year. It has 303 pubs and hotels in South East England, predominantly in Kent and London. The company exports to 44 countries, including India, Sweden, Italy, Brazil, and Canada.

Homebrewing is the brewing of beer or other alcoholic beverages on a small scale for personal, non-commercial purposes. Supplies, such as kits and fermentation tanks, can be purchased locally at specialty stores or online. Beer was brewed domestically for thousands of years before its commercial production, although its legality has varied according to local regulation. Homebrewing is closely related to the hobby of home distillation, the production of alcoholic spirits for personal consumption; however home distillation is generally more tightly regulated.

Sahti is a Finnish type of farmhouse ale made from malted and unmalted grains including barley and rye. Traditionally the beer is flavored with juniper in addition to, or instead of, hops; the mash is filtered through juniper twigs into a trough-shaped tun, called a kuurna in Finnish. Sahti is top-fermented and many have a banana flavor due to isoamyl acetate from the use of baking yeast, although ale yeast may also be used in fermenting.

In brewing and distilling, mashing is the process of combining a mix of ground grains – typically malted barley with supplementary grains such as corn, sorghum, rye, or wheat – known as the "grain bill" with water and then heating the mixture. Mashing allows the enzymes in the malt to break down the starch in the grain into sugars, typically maltose to create a malty liquid called wort.

Steam beer, also known as California common beer, is made by fermenting lager yeast at a warmer than normal temperature.

Hook Norton Brewery is a regional brewery in Hook Norton, Oxfordshire, England, several miles outside the Cotswold Hills. Founded in 1849, the brewing plant is a traditional Victorian 'tower' brewery in which all the stages of the brewing process flow logically from floor to floor; mashing at the top, boiling in the middle, fermentation and racking at the bottom. Until 2006, the brewing process was powered by steam. Beer is still delivered in the village by horse-drawn dray.

In brewing, adjuncts are unmalted grains or grain products used in brewing beer which supplement the main mash ingredient. This is often done with the intention of cutting costs, but sometimes also to create an additional feature, such as better foam retention, flavours or nutritional value or additives. Both solid and liquid adjuncts are commonly used.

Beer styles differentiate and categorise beers by colour, flavour, strength, ingredients, production method, recipe, history, or origin.

Wrexham Lager is a lager brewed in Wrexham, north-east Wales, tracing its heritage to 1881. After the original brewery's closure in 2000, the brand was revived by the Roberts family in 2011 using an older recipe.

Sour mash is a process used in the distilling industry that uses material from an older batch of mash to adjust the acidity of a new mash. The term can also be used as the name of the type of mash used in such a process, and a bourbon made using this process can be referred to as a sour mash bourbon.

Beer is one of the oldest human-produced drinks. The first chemically confirmed barley-beer – from the area of Mesopotamia, part of modern-day Iraq – dates back to the 5th millennium BCE. The written history of ancient Egypt and Mesopotamia records the use of beer, and the drink has spread throughout the world; a 3,900-year-old Sumerian poem honouring Ninkasi, the patron goddess of brewing, contains the oldest surviving beer-recipe, describing the production of beer from barley bread, and in China, residue on pottery dating from around 5,000 years ago shows that beer was brewed using barley and other grains.

Wort is the liquid extracted from the mashing process during the brewing of beer or whisky. Wort contains the sugars, the most important being maltose and maltotriose, that will be fermented by the brewing yeast to produce alcohol. Wort also contains crucial amino acids to provide nitrogen to the yeast as well as more complex proteins contributing to beer head retention and flavour.

A brewery or brewing company is a business that makes and sells beer. The place at which beer is commercially made is either called a brewery or a beerhouse, where distinct sets of brewing equipment are called plant. The commercial brewing of beer has taken place since at least 2500 BC; in ancient Mesopotamia, brewers derived social sanction and divine protection from the goddess Ninkasi. Brewing was initially a cottage industry, with production taking place at home; by the ninth century, monasteries and farms would produce beer on a larger scale, selling the excess; and by the eleventh and twelfth centuries larger, dedicated breweries with eight to ten workers were being built.

Beer is produced through steeping a sugar source in water and then fermenting with yeast. Brewing has taken place since around the 6th millennium BC, and archeological evidence suggests that this technique was used in ancient Egypt. Descriptions of various beer recipes can be found in Sumerian writings, some of the oldest known writing of any sort. Brewing is done in a brewery by a brewer, and the brewing industry is part of most western economies. In 19th century Britain, technological discoveries and improvements such as Burtonisation and the Burton Union system significantly changed beer brewing.

Grodziskie is a historical beer style from Poland made from oak-smoked wheat malt with a clear, light golden color, high carbonation, low alcohol content, low to moderate levels of hop bitterness, and a strong smoke flavor and aroma. The taste is light and crisp, with primary flavors coming from the smoked malt, the high mineral content of the water, and the strain of yeast used to ferment it. It was nicknamed "Polish Champagne" because of its high carbonation levels and valued as a high-quality beer for special occasions.

Gotlandsdricka is a traditional homebrewed alcoholic beverage made on the island of Gotland, Sweden. It is a kind of ale, closely related to the Finnish sahti, and Norwegian Maltøl with a smoky, bitter-sweet, spicy (juniper) flavor. It is similar to gruit.

Burukutu is an alcoholic beverage, brewed from the grains of Guinea corn and millet. The alcoholic beverage is often produced in Tropical African countries such as Nigeria, Togo, Kenya, Ethiopia and Burundi as one of the major traditional and local alcoholic drinks. It is commonly consumed in Northern Guinea savanna region of Nigeria, Ghana, Togo, and Republic of Benin.

A beerfault or defect is a flavour deterioration caused by chemical changes of organic compounds in beer, either due to improper production processes or storage. Chemicals that can cause flavour defects in beer are aldehydes, lipids, and sulfur compounds. Just small fluctuations within fermentation byproducts can have a huge impact on the flavour. When the concentration of one or more of these chemicals exceeds the standard threshold, the flavour characteristics change, creating a flavour defect.