Related Research Articles

A pump is a device that moves fluids, or sometimes slurries, by mechanical action, typically converted from electrical energy into hydraulic energy.

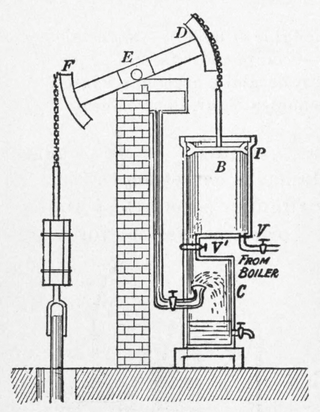

A reciprocating engine, also often known as a piston engine, is typically a heat engine that uses one or more reciprocating pistons to convert high temperature and high pressure into a rotating motion. This article describes the common features of all types. The main types are: the internal combustion engine, used extensively in motor vehicles; the steam engine, the mainstay of the Industrial Revolution; and the Stirling engine for niche applications. Internal combustion engines are further classified in two ways: either a spark-ignition (SI) engine, where the spark plug initiates the combustion; or a compression-ignition (CI) engine, where the air within the cylinder is compressed, thus heating it, so that the heated air ignites fuel that is injected then or earlier.

The Wankel engine is a type of internal combustion engine using an eccentric rotary design to convert pressure into rotating motion. The concept was proven by German engineer Felix Wankel, followed a commercially feasible engine designed by German engineer Hanns-Dieter Paschke. The Wankel engine's rotor, which creates the turning motion, is similar in shape to a Reuleaux triangle, with the sides having less curvature. The rotor spins inside a figure-eight-like epitrochoidal housing, around a fixed toothed gearing. The midpoint of the rotor moves in a circle around the output shaft, spinning the shaft via a cam.

A potentiometer is a three-terminal resistor with a sliding or rotating contact that forms an adjustable voltage divider. If only two terminals are used, one end and the wiper, it acts as a variable resistor or rheostat.

A windscreen wiper or windshield wiper is a device used to remove rain, snow, ice, washer fluid, water, or debris from a vehicle's front window. Almost all motor vehicles, including cars, trucks, buses, train locomotives, and watercraft with a cabin—and some aircraft—are equipped with one or more such wipers, which are usually a legal requirement.

A compressor is a mechanical device that increases the pressure of a gas by reducing its volume. An air compressor is a specific type of gas compressor.

In electrical control engineering, a stepping switch or stepping relay, also known as a uniselector, is an electromechanical device that switches an input signal path to one of several possible output paths, directed by a train of electrical pulses.

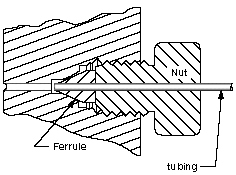

A mechanical seal is a device that helps join systems and mechanisms together by preventing leakage, containing pressure, or excluding contamination. The effectiveness of a seal is dependent on adhesion in the case of sealants and compression in the case of gaskets. The seals are installed in pumps in a wide range of industries including chemicals, water supply, paper production, food processing and many other applications.

A scroll compressor is a device for compressing air or refrigerant. It is used in air conditioning equipment, as an automobile supercharger and as a vacuum pump. Many residential central heat pump and air conditioning systems and a few automotive air conditioning systems employ a scroll compressor instead of the more traditional rotary, reciprocating, and wobble-plate compressors.

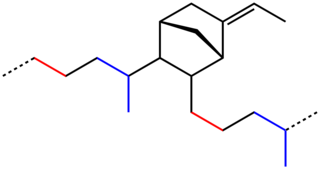

EPDM rubber is a type of synthetic rubber that is used in many applications. Dienes used in the manufacture of EPDM rubbers are ethylidene norbornene (ENB), dicyclopentadiene (DCPD), and vinyl norbornene (VNB). 4-8% of these monomers are typically used.

A stuffing box or gland package is an assembly which is used to house a gland seal. It is used to prevent leakage of fluid, such as water or steam, between sliding or turning parts of machine elements.

A thermal power station is a type of power station in which heat energy is converted to electrical energy. In a steam-generating cycle heat is used to boil water in a large pressure vessel to produce high-pressure steam, which drives a steam turbine connected to an electrical generator. The low-pressure exhaust from the turbine enters a steam condenser where it is cooled to produce hot condensate which is recycled to the heating process to generate more high pressure steam. This is known as a Rankine cycle.

Reciprocating motion, also called reciprocation, is a repetitive up-and-down or back-and-forth linear motion. It is found in a wide range of mechanisms, including reciprocating engines and pumps. The two opposite motions that comprise a single reciprocation cycle are called strokes.

A hydraulic cylinder is a mechanical actuator that is used to give a unidirectional force through a unidirectional stroke. It has many applications, notably in construction equipment, manufacturing machinery, elevators, and civil engineering. A hydraulic cylinder is a hydraulic actuator that provides linear motion when hydraulic energy is converted into mechanical movement. It can be likened to a muscle in that, when the hydraulic system of a machine is activated, the cylinder is responsible for providing the motion.

An axial piston pump is a positive displacement pump that has a number of pistons in a circular array within a cylinder block.

A hydraulic seal is a relatively soft, non-metallic ring, captured in a groove or fixed in a combination of rings, forming a seal assembly, to block or separate fluid in reciprocating motion applications. Hydraulic seals are vital in machinery. Their use is critical in providing a way for fluid power to be converted to linear motion.

A swashplate, also known as slant disk, is a mechanical engineering device used to translate the motion of a rotating shaft into reciprocating motion, or vice versa. The working principle is similar to crankshaft, Scotch yoke, or wobble/nutator/Z-crank drives, in engine designs. It was originally invented to replace a crankshaft, and is one of the most popular concepts used in crankless engines. It was invented by Anthony Michell in 1917.

A rotary actuator is an actuator that produces a rotary motion or torque.

In mechanical engineering, the cylinders of reciprocating engines are often classified by whether they are single- or double-acting, depending on how the working fluid acts on the piston.

References

- ↑ Fitch, E. C. (2013). Proactive Maintenance for Mechanical Systems. p. 36. ISBN 9781483292595 . Retrieved 2023-06-03.