An air hammer, also known as an air chisel, is a pneumatic hand tool used to carve in stone, and to break or cut metal objects apart. It is designed to accept different tools depending on the required function. [1]

An air hammer, also known as an air chisel, is a pneumatic hand tool used to carve in stone, and to break or cut metal objects apart. It is designed to accept different tools depending on the required function. [1]

The following are various tools that can be used in an air hammer: [1]

Free-standing air hammers are an adaptation of the hand-held version. An air hammer can stretch or shrink (shape) a variety of metals, from thin aircraft aluminums, all the way down to 10-gauge steel. They are also used for smoothing metal that has already been roughed, shaped or formed. [2]

| | This section needs expansion. You can help by adding to it. (September 2017) |

In the 1920s, two pneumatic devices were invented that would permanently change the way metal and stone were hammered. The pneumatic rivet gun was originally developed to set hot rivets on girder bridges and high steel buildings. This tool was later scaled down for sheet metal, as the 1930s saw the advent of monocoque aluminum aircraft. The other new device, hitting at twice or three times the speed of the rivet gun, was the stone carver's hammer – a great blessing for smooth and rapid dressing of granite and marble.

In 1930 F.J. Hauschild adapted the original stone carver's hammer into a portable hand-held steel tube frame for the purpose of straightening auto bodies. For the next 25 years his "Ram's Head Body and Fender Machine" improved and increased production for auto body work men all over the U.S. Copying Hauschild’s patented design, a pneumatic tool company in Chicago marketed a number of "destined-to-be-classic" pneumatic planishing hammers, both hand-held for auto body work, and also free-standing ones, with a variety of throat depths for industry and manufacturing. [3]

By World War II, rivet guns were used widely in U.S. aircraft factories both for riveting aluminum sheets, and for flow forming, the process of working aluminum sheet into and over wooden forms by the application of the pneumatic rivet gun.

Post-war industry brought many new applications for the "air hammer" technology. Among these were:

Each of these tools has a different purpose despite nearly identical appearance in many cases.

A forge is a type of hearth used for heating metals, or the workplace (smithy) where such a hearth is located. The forge is used by the smith to heat a piece of metal to a temperature at which it becomes easier to shape by forging, or to the point at which work hardening no longer occurs. The metal is transported to and from the forge using tongs, which are also used to hold the workpiece on the smithy's anvil while the smith works it with a hammer. Sometimes, such as when hardening steel or cooling the work so that it may be handled with bare hands, the workpiece is transported to the slack tub, which rapidly cools the workpiece in a large body of water. However, depending on the metal type, it may require an oil quench or a salt brine instead; many metals require more than plain water hardening. The slack tub also provides water to control the fire in the forge.

A hammer is a tool, most often a hand tool, consisting of a weighted "head" fixed to a long handle that is swung to deliver an impact to a small area of an object. This can be, for example, to drive nails into wood, to shape metal, or to crush rock. Hammers are used for a wide range of driving, shaping, breaking and non-destructive striking applications. Traditional disciplines include carpentry, blacksmithing, warfare, and percussive musicianship.

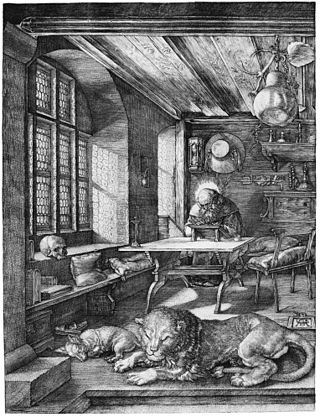

Engraving is the practice of incising a design onto a hard, usually flat surface by cutting grooves into it with a burin. The result may be a decorated object in itself, as when silver, gold, steel, or glass are engraved, or may provide an intaglio printing plate, of copper or another metal, for printing images on paper as prints or illustrations; these images are also called "engravings". Engraving is one of the oldest and most important techniques in printmaking.

A chisel is a tool with a characteristically shaped cutting edge of blade on its end; for carving or cutting a hard material such as wood, stone, or metal by hand, struck with a mallet, or mechanical power. The handle and blade of some types of chisel are made of metal or wood with a sharp edge in it.

A blacksmith is a metalsmith who creates objects primarily from wrought iron or steel, but sometimes from other metals, by forging the metal, using tools to hammer, bend, and cut. Blacksmiths produce objects such as gates, grilles, railings, light fixtures, furniture, sculpture, tools, agricultural implements, decorative and religious items, cooking utensils, and weapons. There was an historical distinction between the heavy work of the blacksmith and the more delicate operation of a whitesmith, who usually worked in gold, silver, pewter, or the finishing steps of fine steel. The place where a blacksmith works is called variously a smithy, a forge or a blacksmith's shop.

Marble has been the preferred material for stone monumental sculpture since ancient times, with several advantages over its more common geological "parent" limestone, in particular the ability to absorb light a small distance into the surface before refracting it in subsurface scattering. This gives an attractive soft appearance that is especially good for representing human skin, which can also be polished.

Metalworking is the process of shaping and reshaping metals to create useful objects, parts, assemblies, and large scale structures. As a term it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale: from huge ships, buildings, and bridges down to precise engine parts and delicate jewelry.

A machinist is a tradesperson or trained professional who operates machine tools, and has the ability to set up tools such as milling machines, grinders, lathes, and drilling machines.

A rivet is a permanent mechanical fastener. Before being installed, a rivet consists of a smooth cylindrical shaft with a head on one end. The end opposite the head is called the tail. On installation, the rivet is placed in a punched or drilled hole, and the tail is upset or bucked, so that it expands to about 1.5 times the original shaft diameter, holding the rivet in place. In other words, the pounding or pulling creates a new "head" on the tail end by smashing the "tail" material flatter, resulting in a rivet that is roughly a dumbbell shape. To distinguish between the two ends of the rivet, the original head is called the factory head and the deformed end is called the shop head or buck-tail.

Stone carving is an activity where pieces of rough natural stone are shaped by the controlled removal of stone. Owing to the permanence of the material, stone work has survived which was created during our prehistory or past time.

A mallet is a tool used for imparting force on another object, often made of rubber or sometimes wood, that is smaller than a maul or beetle, and usually has a relatively large head.

Caulk or, less frequently, caulking is a material used to seal joints or seams against leakage in various structures and piping.

A ball-peen or ball peinhammer, also known as a machinist's hammer, is a type of peening hammer used in metalworking. It has two heads, one flat and the other, called the peen, rounded. It is distinguished from a cross-peen hammer, diagonal-peen hammer, point-peen hammer, or chisel-peen hammer by having a hemispherical peen.

Metalworking hand tools are hand tools that are used in the metalworking field. Hand tools are powered solely by the operator.

The English wheel, in Britain also known as a wheeling machine, is a metalworking tool that enables a craftsperson to form compound curves from flat sheets of metal such as aluminium or steel.

Planishing is a metalworking technique that involves finishing the surface of sheet metal by finely shaping and smoothing it.

A stone sculpture is an object made of stone which has been shaped, usually by carving, or assembled to form a visually interesting three-dimensional shape. Stone is more durable than most alternative materials, making it especially important in architectural sculpture on the outside of buildings.

A rivet gun, also known as a rivet hammer or a pneumatic hammer, is a type of tool used to drive rivets. The rivet gun is used on rivet's factory head, and a bucking bar is used to support the tail of the rivet. The energy from the hammer in the rivet gun drives the work and the rivet against the bucking bar. As a result, the tail of the rivet is compressed and work-hardened. At the same time the work is tightly drawn together and retained between the rivet head and the flattened tail. Nearly all rivet guns are pneumatically powered. Those rivet guns used to drive rivets in structural steel are quite large while those used in aircraft assembly are easily held in one hand. A rivet gun differs from an air hammer in the precision of the driving force.

The Airdrome Eindecker E-III is a single-seat, mid-wing, conventional landing gear fighter aircraft replica produced in kit form by Airdrome Aeroplanes of Holden, Missouri.

Air hammer may refer to: