A ceramic is any of the various hard, brittle, heat-resistant, and corrosion-resistant materials made by shaping and then firing an inorganic, nonmetallic material, such as clay, at a high temperature. Common examples are earthenware, porcelain, and brick.

Sintering or frittage is the process of compacting and forming a solid mass of material by pressure or heat without melting it to the point of liquefaction. Sintering happens as part of a manufacturing process used with metals, ceramics, plastics, and other materials. The nanoparticles in the sintered material diffuse across the boundaries of the particles, fusing the particles together and creating a solid piece.

Glass-ceramics are polycrystalline materials produced through controlled crystallization of base glass, producing a fine uniform dispersion of crystals throughout the bulk material. Crystallization is accomplished by subjecting suitable glasses to a carefully regulated heat treatment schedule, resulting in the nucleation and growth of crystal phases. In many cases, the crystallization process can proceed to near completion, but in a small proportion of processes, the residual glass phase often remains.

Many ceramic materials, both glassy and crystalline, have found use as optically transparent materials in various forms from bulk solid-state components to high surface area forms such as thin films, coatings, and fibers. Such devices have found widespread use for various applications in the electro-optical field including: optical fibers for guided lightwave transmission, optical switches, laser amplifiers and lenses, hosts for solid-state lasers and optical window materials for gas lasers, and infrared (IR) heat seeking devices for missile guidance systems and IR night vision. In commercial and general knowledge domains, it is commonly accepted that transparent ceramics or ceramic glass are varieties of strengthened glass, such as those used for the screen glass on an iPhone.

An electroactive polymer (EAP) is a polymer that exhibits a change in size or shape when stimulated by an electric field. The most common applications of this type of material are in actuators and sensors. A typical characteristic property of an EAP is that they will undergo a large amount of deformation while sustaining large forces.

In materials science, the sol–gel process is a method for producing solid materials from small molecules. The method is used for the fabrication of metal oxides, especially the oxides of silicon (Si) and titanium (Ti). The process involves conversion of monomers into a colloidal solution (sol) that acts as the precursor for an integrated network of either discrete particles or network polymers. Typical precursors are metal alkoxides. Sol–gel process is used to produce ceramic nanoparticles.

A ferrite is an iron oxide-containing magnetic ceramic material. They are ferrimagnetic, meaning they are attracted by magnetic fields and can be magnetized to become permanent magnets. Unlike many ferromagnetic materials, most ferrites are not electrically conductive, making them useful in applications like magnetic cores for transformers to suppress eddy currents.

Freeze-gelation, is a form of sol-gel processing of ceramics that enables a ceramic object to be fabricated in complex shapes, without the need for high-temperature sintering. The process is similar to freeze-casting.

Barium titanate (BTO) is an inorganic compound with chemical formula BaTiO3. Barium titanate appears white as a powder and is transparent when prepared as large crystals. It is a ferroelectric, pyroelectric, and piezoelectric ceramic material that exhibits the photorefractive effect. It is used in capacitors, electromechanical transducers and nonlinear optics.

Molybdenum disilicide (MoSi2, or molybdenum silicide), an intermetallic compound, a silicide of molybdenum, is a refractory ceramic with primary use in heating elements. It has moderate density, melting point 2030 °C, and is electrically conductive. At high temperatures it forms a passivation layer of silicon dioxide, protecting it from further oxidation. The thermal stability of MoSi2 alongside its high emissivity make this material, alongside WSi2 attractive for applications as a high emissivity coatings in heat shields for atmospheric entry. MoSi2 is a gray metallic-looking material with tetragonal crystal structure (alpha-modification); its beta-modification is hexagonal and unstable. It is insoluble in most acids but soluble in nitric acid and hydrofluoric acid.

Silicon nitride is a chemical compound of the elements silicon and nitrogen. Si

3N

4 is the most thermodynamically stable and commercially important of the silicon nitrides, and the term ″Silicon nitride″ commonly refers to this specific composition. It is a white, high-melting-point solid that is relatively chemically inert, being attacked by dilute HF and hot H

3PO

4. It is very hard. It has a high thermal stability with strong optical nonlinearities for all-optical applications.

Ceramic engineering is the science and technology of creating objects from inorganic, non-metallic materials. This is done either by the action of heat, or at lower temperatures using precipitation reactions from high-purity chemical solutions. The term includes the purification of raw materials, the study and production of the chemical compounds concerned, their formation into components and the study of their structure, composition and properties.

A nanocrystalline (NC) material is a polycrystalline material with a crystallite size of only a few nanometers. These materials fill the gap between amorphous materials without any long range order and conventional coarse-grained materials. Definitions vary, but nanocrystalline material is commonly defined as a crystallite (grain) size below 100 nm. Grain sizes from 100 to 500 nm are typically considered "ultrafine" grains.

Ceramic foam is a tough foam made from ceramics. Manufacturing techniques include impregnating open-cell polymer foams internally with ceramic slurry and then firing in a kiln, leaving only ceramic material. The foams may consist of several ceramic materials such as aluminium oxide, a common high-temperature ceramic, and gets insulating properties from the many tiny air-filled voids within the material.

Solid is one of the four fundamental states of matter along with liquid, gas, and plasma. The molecules in a solid are closely packed together and contain the least amount of kinetic energy. A solid is characterized by structural rigidity and resistance to a force applied to the surface. Unlike a liquid, a solid object does not flow to take on the shape of its container, nor does it expand to fill the entire available volume like a gas. The atoms in a solid are bound to each other, either in a regular geometric lattice, or irregularly. Solids cannot be compressed with little pressure whereas gases can be compressed with little pressure because the molecules in a gas are loosely packed.

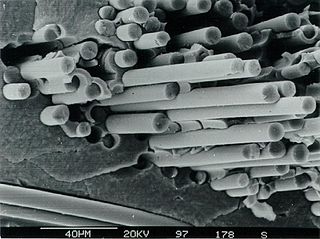

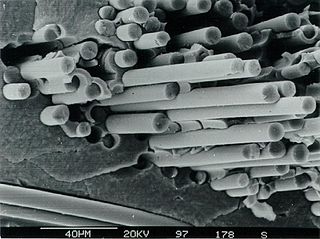

In materials science ceramic matrix composites (CMCs) are a subgroup of composite materials and a subgroup of ceramics. They consist of ceramic fibers embedded in a ceramic matrix. The fibers and the matrix both can consist of any ceramic material, including carbon and carbon fibers.

Hot pressing is a high-pressure, low-strain-rate powder metallurgy process for forming of a powder or powder compact at a temperature high enough to induce sintering and creep processes. This is achieved by the simultaneous application of heat and pressure.

Compaction of ceramic powders is a forming technique for ceramics in which granular ceramic materials are made cohesive through mechanical densification, either by hot or cold pressing. The resulting green part must later be sintered in a kiln. The compaction process permits an efficient production of parts to close tolerances with low drying shrinkage. It can be used for parts ranging widely in size and shape, and for both technical and nontechnical ceramics.

The room-temperature densification method was developed for Li2MoO4 ceramics and is based on the water-solubility of Li2MoO4. It can be used for the fabrication of Li2MoO4 ceramics instead of conventional thermal sintering. The method utilizes a small amount of aqueous phase formed by moistening the Li2MoO4 powder. The densification occurs during sample pressing as the solution incorporates the pores between the powder particles and recrystallizes. The contact points of the particles provide a high pressure zone, where solubility is increased, whereas the pores act as a suitable place for the precipitation of the solution. Any residual water is removed by post-processing typically at 120 °C. The method is suitable also for Li2MoO4 composite ceramics with up to 30 volume-% of filler material, enabling the optimization of the dielectric properties.

Heli Maarit Jantunen is a Finnish Professor of Technology at the University of Oulu and a member of the Scientific Advisory Board for the National Defense. She works on microelectronics and is a member of the 6G Flagship.