Metallurgy is a domain of materials science and engineering that studies the physical and chemical behavior of metallic elements, their inter-metallic compounds, and their mixtures, which are known as alloys.

Powder metallurgy (PM) is a term covering a wide range of ways in which materials or components are made from metal powders. PM processes can reduce or eliminate the need for subtractive processes in manufacturing, lowering material losses and reducing the cost of the final product.

Since the mid-20th century, electron-beam technology has provided the basis for a variety of novel and specialized applications in semiconductor manufacturing, microelectromechanical systems, nanoelectromechanical systems, and microscopy.

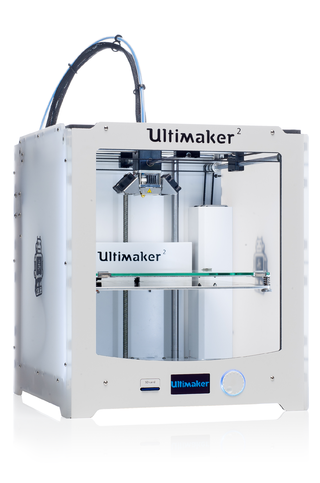

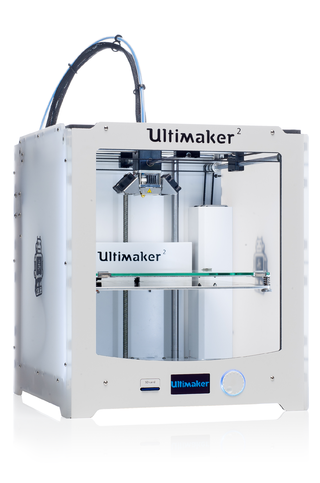

3D printing or additive manufacturing is the construction of a three-dimensional object from a CAD model or a digital 3D model. It can be done in a variety of processes in which material is deposited, joined or solidified under computer control, with the material being added together, typically layer by layer.

Inconel is a nickel-chromium-based superalloy often utilized in extreme environments where components are subjected to high temperature, pressure or mechanical loads. Inconel alloys are oxidation- and corrosion-resistant. When heated, Inconel forms a thick, stable, passivating oxide layer protecting the surface from further attack. Inconel retains strength over a wide temperature range, attractive for high-temperature applications where aluminium and steel would succumb to creep as a result of thermally-induced crystal vacancies. Inconel's high-temperature strength is developed by solid solution strengthening or precipitation hardening, depending on the alloy.

Titanium alloys are alloys that contain a mixture of titanium and other chemical elements. Such alloys have very high tensile strength and toughness. They are light in weight, have extraordinary corrosion resistance and the ability to withstand extreme temperatures. However, the high cost of both raw materials and processing limit their use to military applications, aircraft, spacecraft, bicycles, medical devices, jewelry, highly stressed components such as connecting rods on expensive sports cars and some premium sports equipment and consumer electronics.

Microstructure is the very small scale structure of a material, defined as the structure of a prepared surface of material as revealed by an optical microscope above 25× magnification. The microstructure of a material can strongly influence physical properties such as strength, toughness, ductility, hardness, corrosion resistance, high/low temperature behaviour or wear resistance. These properties in turn govern the application of these materials in industrial practice.

Laser powder forming, also known by the proprietary name is an additive manufacturing technology developed for fabricating metal parts directly from a computer-aided design (CAD) solid model by using a metal powder injected into a molten pool created by a focused, high-powered laser beam. This technique is also equivalent to several trademarked techniques that have the monikers direct metal deposition (DMD), and laser consolidation (LC). Compared to processes that use powder beds, such as selective laser melting (SLM) objects created with this technology can be substantially larger, even up to several feet long.

Gas dynamic cold spraying or cold spraying (CS) is a coating deposition method. Solid powders are accelerated in a supersonic gas jet to velocities up to ca. 1200 m/s. During impact with the substrate, particles undergo plastic deformation and adhere to the surface. To achieve a uniform thickness the spraying nozzle is scanned along the substrate. Metals, polymers, ceramics, composite materials and nanocrystalline powders can be deposited using cold spraying. The kinetic energy of the particles, supplied by the expansion of the gas, is converted to plastic deformation energy during bonding. Unlike thermal spraying techniques, e.g., plasma spraying, arc spraying, flame spraying, or high velocity oxygen fuel (HVOF), the powders are not melted during the spraying process.

Arcam AB manufactures electron beam melting (EBM) systems for use in additive manufacturing, which create solid parts from metal powders. Arcam also produces metal powder through AP&C and medical implants through DiSanto Technologies.

Electron-beam freeform fabrication (EBF3) is an additive manufacturing process that builds near-net-shape parts. It requires far less raw material and finish machining than traditional manufacturing methods. EBF3 is done in a vacuum chamber where an electron beam is focused on a constantly feeding source of metal, which is melted and applied as called for by a three-dimensional layered drawing - one layer at a time - on top of a rotating metallic substrate until the part is complete.

Ultrasonic Consolidation (UC) or Ultrasonic Additive Manufacturing (UAM) is a low temperature additive manufacturing or 3D printing technique for metals.

Selective laser melting (SLM) is one of many proprietary names for a metal additive manufacturing (AM) technology that uses a bed of powder with a source of heat to create metal parts. Also known as direct metal laser sintering (DMLS), the ASTM standard term is powder bed fusion (PBF). PBF is a rapid prototyping, 3D printing, or additive manufacturing technique designed to use a high power-density laser to melt and fuse metallic powders together.

Binder jet 3D printing, known variously as "Powder bed and inkjet" and "drop-on-powder" printing, is a rapid prototyping and additive manufacturing technology for making objects described by digital data such as a CAD file. Binder jetting is one of the seven categories of additive manufacturing processes according to ASTM and ISO.

Sciaky, Inc. is an American manufacturer of metal 3d printing systems and industrial welding systems, founded in 1939 and headquartered in Chicago, Illinois. It specializes in electron beam welding systems and services for aerospace manufacturers.

A variety of processes, equipment, and materials are used in the production of a three-dimensional object via additive manufacturing. 3D printing is also known as additive manufacturing, because the numerous available 3D printing process tend to be additive in nature, with a few key differences in the technologies and the materials used in this process.

Cold spray additive manufacturing (CSAM) is a particular application of cold spraying, able to fabricate freestanding parts or to build features on existing components. During the process, fine powder particles are accelerated in a high-velocity compressed gas stream, and upon the impact on a substrate or backing plate, deform and bond together creating a layer. Moving the nozzle over a substrate repeatedly, a deposit is building up layer-by-layer, to form a part or component. If an industrial robot or computer controlled manipulator controls the spray gun movements, complex shapes can be created. To achieve a 3D shape, there are two different approaches. First, to fix the substrate and move the cold spray gun/nozzle using a robotic arm; the second one is to move the substrate with a robotic arm, and keep the spray-gun nozzle fixed. There is also a possibility to combine these two approaches either using two robotic arms or other manipulators. The process always requires a substrate and uses only powder as raw material.

Research on the health and safety hazards of 3D printing is new and in development due to the recent proliferation of 3D printing devices. In 2017, the European Agency for Safety and Health at Work has published a discussion paper on the processes and materials involved in 3D printing, potential implications of this technology for occupational safety and health and avenues for controlling potential hazards.

AlSi10Mg is a lightweight, high-strength aluminium alloy that is widely used in the aerospace, automotive, and medical industries. Its unique combination of aluminium, silicon, and magnesium makes it an ideal material for additive manufacturing processes, such as 3D printing.

Laser metal deposition (LMD) is an additive manufacturing process in which a feedstock material is melted with a laser and then deposited onto a substrate. A variety of pure metals and alloys can be used as the feedstock, as well as composite materials such as metal matrix composites. Laser sources with a wide variety of intensities, wavelengths, and optical configurations can be used. While LMD is typically a melt-based process, this is not a requirement, as discussed below. Melt-based processes typically have a strength advantage, due to achieving a full metallurgical fusion.