Related Research Articles

An analog computer or analogue computer is a type of computer that uses the continuous variation aspect of physical phenomena such as electrical, mechanical, or hydraulic quantities to model the problem being solved. In contrast, digital computers represent varying quantities symbolically and by discrete values of both time and amplitude.

An ammeter is an instrument used to measure the current in a circuit. Electric currents are measured in amperes (A), hence the name. For direct measurement, the ammeter is connected in series with the circuit in which the current is to be measured. An ammeter usually has low resistance so that it does not cause a significant voltage drop in the circuit being measured.

Pressure measurement is the measurement of an applied force by a fluid on a surface. Pressure is typically measured in units of force per unit of surface area. Many techniques have been developed for the measurement of pressure and vacuum. Instruments used to measure and display pressure mechanically are called pressure gauges,vacuum gauges or compound gauges. The widely used Bourdon gauge is a mechanical device, which both measures and indicates and is probably the best known type of gauge.

A galvanometer is an electromechanical measuring instrument for electric current. Early galvanometers were uncalibrated, but improved versions, called ammeters, were calibrated and could measure the flow of current more precisely. Galvanometers work by deflecting a pointer in response to an electric current flowing through a coil in a constant magnetic field. The mechanism is also used as an actuator in applications such as hard disks.

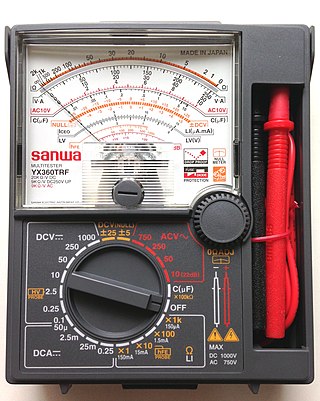

A multimeter is a measuring instrument that can measure multiple electrical properties. A typical multimeter can measure voltage, resistance, and current, in which case can be used as a voltmeter, ohmmeter, and ammeter. Some feature the measurement of additional properties such as temperature and capacitance.

A micrometer, sometimes known as a micrometer screw gauge, is a device incorporating a calibrated screw widely used for accurate measurement of components in mechanical engineering and machining as well as most mechanical trades, along with other metrological instruments such as dial, vernier, and digital calipers. Micrometers are usually, but not always, in the form of calipers. The spindle is a very accurately machined screw and the object to be measured is placed between the spindle and the anvil. The spindle is moved by turning the ratchet knob or thimble until the object to be measured is lightly touched by both the spindle and the anvil.

A ruler, sometimes called a rule, scale or a line gauge, is an instrument used to make length measurements, whereby a user estimates a length by reading from a series of markings called "rules" along an edge of the device. Commonly the instrument is rigid and the edge itself is a straightedge, which additionally allows one to draw straight lines. Some rulers, such as cloth or paper tape measures, are non-rigid. Specialty rulers exist that have flexible edges that retain a chosen shape; these find use in sewing, arts, and crafts.

Flight instruments are the instruments in the cockpit of an aircraft that provide the pilot with data about the flight situation of that aircraft, such as altitude, airspeed, vertical speed, heading and much more other crucial information in flight. They improve safety by allowing the pilot to fly the aircraft in level flight, and make turns, without a reference outside the aircraft such as the horizon. Visual flight rules (VFR) require an airspeed indicator, an altimeter, and a compass or other suitable magnetic direction indicator. Instrument flight rules (IFR) additionally require a gyroscopic pitch-bank, direction and rate of turn indicator, plus a slip-skid indicator, adjustable altimeter, and a clock. Flight into instrument meteorological conditions (IMC) require radio navigation instruments for precise takeoffs and landings.

A flight simulator is a device that artificially re-creates aircraft flight and the environment in which it flies, for pilot training, design, or other purposes. It includes replicating the equations that govern how aircraft fly, how they react to applications of flight controls, the effects of other aircraft systems, and how the aircraft reacts to external factors such as air density, turbulence, wind shear, cloud, precipitation, etc. Flight simulation is used for a variety of reasons, including flight training, the design and development of the aircraft itself, and research into aircraft characteristics and control handling qualities.

A glass cockpit is an aircraft cockpit that features an array of electronic (digital) flight instrument displays, typically large LCD screens, rather than traditional analog dials and gauges. While a traditional cockpit relies on numerous mechanical gauges to display information, a glass cockpit uses several multi-function displays driven by flight management systems, that can be adjusted to display flight information as needed. This simplifies aircraft operation and navigation and allows pilots to focus only on the most pertinent information. They are also popular with airline companies as they usually eliminate the need for a flight engineer, saving costs. In recent years the technology has also become widely available in small aircraft.

A dashboard is a control panel set within the central console of a vehicle or cockpit of an aircraft or spacecraft. Usually located directly ahead of the driver, it displays instrumentation and controls for the vehicle's operation. An electronic equivalent may be called an electronic instrument cluster, digital instrument panel, digital dash, digital speedometer or digital instrument cluster.

In aviation, an electronic flight instrument system (EFIS) is a flight instrument display system in an aircraft cockpit that displays flight data electronically rather than electromechanically. An EFIS normally consists of a primary flight display (PFD), multi-function display (MFD), and an engine indicating and crew alerting system (EICAS) display. Early EFIS models used cathode ray tube (CRT) displays, but liquid crystal displays (LCD) are now more common. The complex electromechanical attitude director indicator (ADI) and horizontal situation indicator (HSI) were the first candidates for replacement by EFIS. Now, however, few flight deck instruments cannot be replaced by an electronic display.

In various contexts of science, technology, and manufacturing, an indicator is any of various instruments used to accurately measure small distances and angles, and amplify them to make them more obvious. The name comes from the concept of indicating to the user that which their naked eye cannot discern; such as the presence, or exact quantity, of some small distance.

A bore gauge is a collective term for the tools that are unique to the process of accurately measuring holes.

A pitot–static system is a system of pressure-sensitive instruments that is most often used in aviation to determine an aircraft's airspeed, Mach number, altitude, and altitude trend. A pitot–static system generally consists of a pitot tube, a static port, and the pitot–static instruments. Other instruments that might be connected are air data computers, flight data recorders, altitude encoders, cabin pressurization controllers, and various airspeed switches. Errors in pitot–static system readings can be extremely dangerous as the information obtained from the pitot static system, such as altitude, is potentially safety-critical. Several commercial airline disasters have been traced to a failure of the pitot–static system.

A peak programme meter (PPM) is an instrument used in professional audio that indicates the level of an audio signal.

A primary flight display or PFD is a modern aircraft instrument dedicated to flight information. Much like multi-function displays, primary flight displays are built around a Liquid-crystal display or CRT display device. Representations of older six pack or "steam gauge" instruments are combined on one compact display, simplifying pilot workflow and streamlining cockpit layouts.

A trip computer is a computer fitted to some cars; most modern trip computers record, calculate, and display the distance travelled, the average speed, the average fuel consumption, and real-time fuel consumption.

Altitude can be determined based on the measurement of atmospheric pressure. The greater the altitude, the lower the pressure. When a barometer is supplied with a nonlinear calibration so as to indicate altitude, the instrument is a type of altimeter called a pressure altimeter or barometric altimeter. A pressure altimeter is the altimeter found in most aircraft, and skydivers use wrist-mounted versions for similar purposes. Hikers and mountain climbers use wrist-mounted or hand-held altimeters, in addition to other navigational tools such as a map, magnetic compass, or GPS receiver.

An oscilloscope is a type of electronic test instrument that graphically displays varying voltages of one or more signals as a function of time. Their main purpose is capturing information on electrical signals for debugging, analysis, or characterization. The displayed waveform can then be analyzed for properties such as amplitude, frequency, rise time, time interval, distortion, and others. Originally, calculation of these values required manually measuring the waveform against the scales built into the screen of the instrument. Modern digital instruments may calculate and display these properties directly.

References

- ↑ Ray Herren, Agricultural Mechanics: Fundamentals & Applications (2009), p. 109.

- 1 2 Barry Hollembeak, Today's Technician: Automotive Electricity and Electronics (2010).

- ↑ "Hole Gauge(H7)". www.protool-ltd.co.uk. Protool Ltd.