Occupational hygiene is the anticipation, recognition, evaluation, control, and confirmation (ARECC) of protection from risks associated with exposures to hazards in, or arising from, the workplace that may result in injury, illness, impairment, or affect the well-being of workers and members of the community. These hazards or stressors are typically divided into the categories biological, chemical, physical, ergonomic and psychosocial. The risk of a health effect from a given stressor is a function of the hazard multiplied by the exposure to the individual or group. For chemicals, the hazard can be understood by the dose response profile most often based on toxicological studies or models. Occupational hygienists work closely with toxicologists for understanding chemical hazards, physicists for physical hazards, and physicians and microbiologists for biological hazards. Environmental and occupational hygienists are considered experts in exposure science and exposure risk management. Depending on an individual's type of job, a hygienist will apply their exposure science expertise for the protection of workers, consumers and/or communities.

Nanomaterials describe, in principle, materials of which a single unit is sized between 1 and 100 nm.

Nanotoxicology is the study of the toxicity of nanomaterials. Because of quantum size effects and large surface area to volume ratio, nanomaterials have unique properties compared with their larger counterparts that affect their toxicity. Of the possible hazards, inhalation exposure appears to present the most concern, with animal studies showing pulmonary effects such as inflammation, fibrosis, and carcinogenicity for some nanomaterials. Skin contact and ingestion exposure are also a concern.

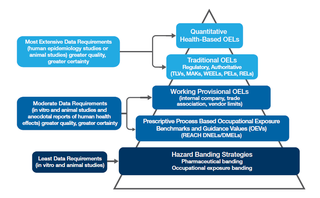

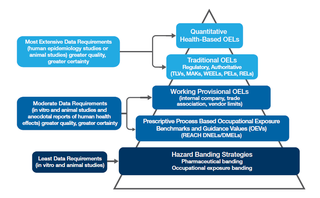

An occupational exposure limit is an upper limit on the acceptable concentration of a hazardous substance in workplace air for a particular material or class of materials. It is typically set by competent national authorities and enforced by legislation to protect occupational safety and health. It is an important tool in risk assessment and in the management of activities involving handling of dangerous substances. There are many dangerous substances for which there are no formal occupational exposure limits. In these cases, hazard banding or control banding strategies can be used to ensure safe handling.

Workplace health surveillance or occupational health surveillance (U.S.) is the ongoing systematic collection, analysis, and dissemination of exposure and health data on groups of workers. The Joint ILO/WHO Committee on Occupational Health at its 12th Session in 1995 defined an occupational health surveillance system as "a system which includes a functional capacity for data collection, analysis and dissemination linked to occupational health programmes".

Prevention through design (PtD), also called safety by design usually in Europe, is the concept of applying methods to minimize occupational hazards early in the design process, with an emphasis on optimizing employee health and safety throughout the life cycle of materials and processes. It is a concept and movement that encourages construction or product designers to "design out" health and safety risks during design development. The concept supports the view that along with quality, programme and cost; safety is determined during the design stage. It increases the cost-effectiveness of enhancements to occupational safety and health.

The substitution of dangerous chemicals in the workplace is the process of replacing chemicals with less hazardous alternatives or eliminating them, generally to improve occupational health and safety or minimize harmful environmental impact. The process can be lengthy, as an assessment of dangers, costs, and practicality is necessary. Substituting hazardous chemicals follows the principles of green chemistry and results in clean technology.

Hierarchy of hazard control is a system used in industry to minimize or eliminate exposure to hazards. It is a widely accepted system promoted by numerous safety organizations. This concept is taught to managers in industry, to be promoted as standard practice in the workplace. It has also been used to inform public policy, in fields such as road safety. Various illustrations are used to depict this system, most commonly a triangle.

Engineering controls are strategies designed to protect workers from hazardous conditions by placing a barrier between the worker and the hazard or by removing a hazardous substance through air ventilation. Engineering controls involve a physical change to the workplace itself, rather than relying on workers' behavior or requiring workers to wear protective clothing.

Alternatives assessment or alternatives analysis is a problem-solving approach used in environmental design, technology, and policy. It aims to minimize environmental harm by comparing multiple potential solutions in the context of a specific problem, design goal, or policy objective. It is intended to inform decision-making in situations with many possible courses of action, a wide range of variables to consider, and significant degrees of uncertainty. Alternatives assessment was originally developed as a robust way to guide precautionary action and avoid paralysis by analysis; authors such as O'Brien have presented alternatives assessment as an approach that is complementary to risk assessment, the dominant decision-making approach in environmental policy. Likewise, Ashford has described the similar concept of technology options analysis as a way to generate innovative solutions to the problems of industrial pollution more effectively than through risk-based regulation.

Occupational dust exposure can occur in various settings, including agriculture, forestry, and mining. Dust hazards include those that arise from handling grain and cotton, as well as from mining coal. Wood dust, commonly referred to as "sawdust", is another occupational dust hazard that can pose a risk to workers' health.

The health and safety hazards of nanomaterials include the potential toxicity of various types of nanomaterials, as well as fire and dust explosion hazards. Because nanotechnology is a recent development, the health and safety effects of exposures to nanomaterials, and what levels of exposure may be acceptable, are subjects of ongoing research. Of the possible hazards, inhalation exposure appears to present the most concern, with animal studies showing pulmonary effects such as inflammation, fibrosis, and carcinogenicity for some nanomaterials. Skin contact and ingestion exposure, and dust explosion hazards, are also a concern.

Hazard elimination is a hazard control strategy based on completely removing a material or process causing a hazard. Elimination is the most effective of the five members of the hierarchy of hazard controls in protecting workers, and where possible should be implemented before all other control methods. Many jurisdictions require that an employer eliminate hazards if it is possible, before considering other types of hazard control.

Occupational exposure banding, also known as hazard banding, is a process intended to quickly and accurately assign chemicals into specific categories (bands), each corresponding to a range of exposure concentrations designed to protect worker health. These bands are assigned based on a chemical’s toxicological potency and the adverse health effects associated with exposure to the chemical. The output of this process is an occupational exposure band (OEB). Occupational exposure banding has been used by the pharmaceutical sector and by some major chemical companies over the past several decades to establish exposure control limits or ranges for new or existing chemicals that do not have formal OELs. Furthermore, occupational exposure banding has become an important component of the Hierarchy of Occupational Exposure Limits (OELs).

Engineering controls for nanomaterials are a set of hazard control methods and equipment for workers who interact with nanomaterials. Engineering controls are physical changes to the workplace that isolate workers from hazards, and are considered the most important set of methods for controlling the health and safety hazards of nanomaterials after systems and facilities have been designed.

A radioactive nanoparticle is a nanoparticle that contains radioactive materials. Radioactive nanoparticles have applications in medical diagnostics, medical imaging, toxicokinetics, and environmental health, and are being investigated for applications in nuclear nanomedicine. Radioactive nanoparticles present special challenges in operational health physics and internal dosimetry that are not present for other substances, although existing radiation protection measures and hazard controls for nanoparticles generally apply.

The characterization of nanoparticles is a branch of nanometrology that deals with the characterization, or measurement, of the physical and chemical properties of nanoparticles. Nanoparticles measure less than 100 nanometers in at least one of their external dimensions, and are often engineered for their unique properties. Nanoparticles are unlike conventional chemicals in that their chemical composition and concentration are not sufficient metrics for a complete description, because they vary in other physical properties such as size, shape, surface properties, crystallinity, and dispersion state.

Titanium dioxide nanoparticles, also called ultrafine titanium dioxide or nanocrystalline titanium dioxide or microcrystalline titanium dioxide, are particles of titanium dioxide with diameters less than 100 nm. Ultrafine TiO2 is used in sunscreens due to its ability to block ultraviolet radiation while remaining transparent on the skin. It is in rutile crystal structure and coated with silica or/and alumina to prevent photocatalytic phenomena. The health risks of ultrafine TiO2 from dermal exposure on intact skin are considered extremely low, and it is considered safer than other substances used for ultraviolet protection.

Anticipate, recognize, evaluate, control, and confirm (ARECC) is a decision-making framework and process used in the field of industrial hygiene (IH) to anticipate and recognize hazards, evaluate exposures, and control and confirm protection from risks. ARECC supports hazard-informed exposure assessment, exposure-informed hazard assessment, and risk-informed decision making in any endeavor.

Research on the health and safety hazards of 3D printing is new and in development due to the recent proliferation of 3D printing devices. In 2017, the European Agency for Safety and Health at Work has published a discussion paper on the processes and materials involved in 3D printing, potential implications of this technology for occupational safety and health and avenues for controlling potential hazards.