Mining is the extraction of valuable geological materials and minerals from the surface of the Earth. Mining is required to obtain most materials that cannot be grown through agricultural processes, or feasibly created artificially in a laboratory or factory. Ores recovered by mining include metals, coal, oil shale, gemstones, limestone, chalk, dimension stone, rock salt, potash, gravel, and clay. The ore must be a rock or mineral that contains valuable constituent, can be extracted or mined and sold for profit. Mining in a wider sense includes extraction of any non-renewable resource such as petroleum, natural gas, or even water.

Open-pit mining, also known as open-cast or open-cut mining and in larger contexts mega-mining, is a surface mining technique that extracts rock or minerals from the earth using a pit, sometimes known as a borrow pit.

Thermal depolymerization (TDP) is the process of converting a polymer into a monomer or a mixture of monomers, by predominantly thermal means. It may be catalysed or un-catalysed and is distinct from other forms of depolymerisation which may rely on the use of chemicals or biological action. This process is associated with an increase in entropy.

Seawater, or sea water, is water from a sea or ocean. On average, seawater in the world's oceans has a salinity of about 3.5%. This means that every kilogram of seawater has approximately 35 grams (1.2 oz) of dissolved salts. The average density at the surface is 1.025 kg/L. Seawater is denser than both fresh water and pure water because the dissolved salts increase the mass by a larger proportion than the volume. The freezing point of seawater decreases as salt concentration increases. At typical salinity, it freezes at about −2 °C (28 °F). The coldest seawater still in the liquid state ever recorded was found in 2010, in a stream under an Antarctic glacier: the measured temperature was −2.6 °C (27.3 °F).

In mining, tailings or tails are the materials left over after the process of separating the valuable fraction from the uneconomic fraction (gangue) of an ore. Tailings are different from overburden, which is the waste rock or other material that overlies an ore or mineral body and is displaced during mining without being processed.

Life cycle assessment (LCA), also known as life cycle analysis, is a methodology for assessing environmental impacts associated with all the stages of the life cycle of a commercial product, process, or service. For instance, in the case of a manufactured product, environmental impacts are assessed from raw material extraction and processing (cradle), through the product's manufacture, distribution and use, to the recycling or final disposal of the materials composing it (grave).

Acid mine drainage, acid and metalliferous drainage (AMD), or acid rock drainage (ARD) is the outflow of acidic water from metal mines and coal mines.

Gold mining is the extraction of gold by mining.

Mine reclamation is the process of modifying land that has been mined to ecologically functional or economically usable state. Although the process of mine reclamation occurs once mining is completed, the planning of mine reclamation activities occurs prior to a mine being permitted or started. Mine reclamation creates useful landscapes that meet a variety of goals ranging from the restoration of productive ecosystems to the creation of industrial and municipal resources. In the United States, mine reclamation is a regular part of modern mining practices. Modern mine reclamation reduces the environmental effects of mining.

A biorefinery is a refinery that converts biomass to energy and other beneficial byproducts. The International Energy Agency Bioenergy Task 42 defined biorefining as "the sustainable processing of biomass into a spectrum of bio-based products and bioenergy ". As refineries, biorefineries can provide multiple chemicals by fractioning an initial raw material (biomass) into multiple intermediates that can be further converted into value-added products. Each refining phase is also referred to as a "cascading phase". The use of biomass as feedstock can provide a benefit by reducing the impacts on the environment, as lower pollutants emissions and reduction in the emissions of hazard products. In addition, biorefineries are intended to achieve the following goals:

- Supply the current fuels and chemical building blocks

- Supply new building blocks for the production of novel materials with disruptive characteristics

- Creation of new jobs, including rural areas

- Valorization of waste

- Achieve the ultimate goal of reducing GHG emissions

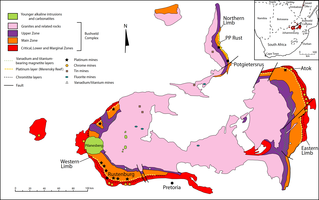

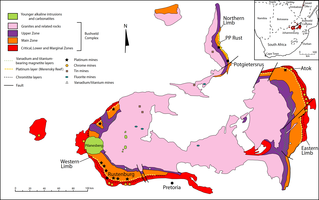

The Bushveld Igneous Complex (BIC) is the largest layered igneous intrusion within the Earth's crust. It has been tilted and eroded forming the outcrops around what appears to be the edge of a great geological basin: the Transvaal Basin. It is approximately two billion years old and is divided into four limbs: northern, eastern, southern and western. It comprises the Rustenburg Layered suite, the Lebowa Granites and the Rooiberg Felsics, that are overlain by the Karoo sediments. The site was first publicised around 1897 by Gustaaf Molengraaff who found the native South African tribes residing in and around the area.

Hydrogen gas is produced by several industrial methods. Nearly all of the world's current supply of hydrogen is created from fossil fuels. Most hydrogen is gray hydrogen made through steam methane reforming. In this process, hydrogen is produced from a chemical reaction between steam and methane, the main component of natural gas. Producing one tonne of hydrogen through this process emits 6.6–9.3 tonnes of carbon dioxide. When carbon capture and storage is used to remove a large fraction of these emissions, the product is known as blue hydrogen.

Design for the environment (DfE) is a design approach to reduce the overall human health and environmental impact of a product, process or service, where impacts are considered across its life cycle. Different software tools have been developed to assist designers in finding optimized products or processes/services. DfE is also the original name of a United States Environmental Protection Agency (EPA) program, created in 1992, that works to prevent pollution, and the risk pollution presents to humans and the environment. The program provides information regarding safer chemical formulations for cleaning and other products. EPA renamed its program "Safer Choice" in 2015.

Hempcrete or hemplime is biocomposite material, a mixture of hemp hurds (shives) and lime, sand, or pozzolans, which is used as a material for construction and insulation. It is marketed under names like Hempcrete, Canobiote, Canosmose, Isochanvre and IsoHemp. Hempcrete is easier to work with than traditional lime mixes and acts as an insulator and moisture regulator. It lacks the brittleness of concrete and consequently does not need expansion joints.

The International Mine Water Association (IMWA) is the first scientific-technical association worldwide dedicated to mine water related topics. Its peer-reviewed journal is Mine Water and the Environment.

Environmental effects of mining can occur at local, regional, and global scales through direct and indirect mining practices. Mining can cause erosion, sinkholes, loss of biodiversity, or the contamination of soil, groundwater, and surface water by chemicals emitted from mining processes. These processes also affect the atmosphere through carbon emissions which contributes to climate change.

GoldSim is dynamic, probabilistic simulation software developed by GoldSim Technology Group. This general-purpose simulator is a hybrid of several simulation approaches, combining an extension of system dynamics with some aspects of discrete event simulation, and embedding the dynamic simulation engine within a Monte Carlo simulation framework.

Mponeng is an ultra-deep tabular gold mine in South Africa in the Witwatersrand Basin of the Gauteng Province. Previously know as Western Deep Levels No1 Shaft, the mine began operations in 1986. It is one of the most substantial gold mine mines in world in terms of production and magnitude, reaching over 4 kilometres (2.5 mi) below the surface. At this depth Mponeng takes the title of world's deepest mine from ground level, with aims to deepen the mine beyond 4km in order to reach more reserves. A trip from the surface to its deepest point takes over an hour, but the harsh conditions of the mine did not stop an Ecuadorian marathon runner from completing a half marathon within the mine. Mponeng comes with economic, environmental, societal, and seismic detrimental costs, but mining in South Africa has had a huge effect on the technologies of deep gold mining around the world, making South Africa a pioneering leader in gold-mining technologies.

The School of Chemical and Metallurgical Engineering is one of seven schools in the University of the Witwatersrand's Faculty of Engineering and the Built Environment. The School offers 4-year undergraduate degrees and post-graduate degrees in chemical and metallurgical engineering.

Aluminum is the third most abundant element in the lithosphere at 82,000 ppm. It occurs in low levels, 0.9 ppm, in humans. Aluminum is known to be an ecotoxicant and expected to be a health risk to people. Global primary production (GPP) of aluminum was about 52 million tons in 2013 and remains one of the world's most important metals. It is used for infrastructure, vehicles, aviation, energy and more due to its lightweight, ductility, and cheap cost. Aluminum is harvested from gibbsite, boehmite, and diaspore which make up bauxite. The aluminum cycle is the biogeochemical cycle by which aluminum is moved through the environment by natural and anthropogenic processes. The biogeochemical cycle of aluminum is integral with silicon and phosphorus. For example, phosphates store aluminum that has been sedimented and aluminum is found in diatoms. Aluminum has been found to prevent growth in organisms by making phosphates less available. The humans/lithosphere ratio (B/L) is very low at 0.000011. This level shows that aluminum is more essential in the lithospheric cycle than in the biotic cycle.