Enterprise resource planning (ERP) is the integrated management of main business processes, often in real time and mediated by software and technology. ERP is usually referred to as a category of business management software—typically a suite of integrated applications—that an organization can use to collect, store, manage and interpret data from many business activities. ERP systems can be local-based or cloud-based. Cloud-based applications have grown in recent years due to the increased efficiencies arising from information being readily available from any location with Internet access.

In commerce, supply chain management (SCM) deals with a system of procurement, operations management, logistics and marketing channels, through which raw materials can be developed into finished products and delivered to their end customers. A more narrow definition of supply chain management is the "design, planning, execution, control, and monitoring of supply chain activities with the objective of creating net value, building a competitive infrastructure, leveraging worldwide logistics, synchronising supply with demand and measuring performance globally". This can include the movement and storage of raw materials, work-in-process inventory, finished goods, and end to end order fulfilment from the point of origin to the point of consumption. Interconnected, interrelated or interlinked networks, channels and node businesses combine in the provision of products and services required by end customers in a supply chain.

A supply chain, sometimes expressed as a "supply-chain", is a complex logistics system that consists of facilities that convert raw materials into finished products and distribute them to end consumers or end customers. Meanwhile, supply chain management deals with the flow of goods within the supply chain in the most efficient manner.

A value chain is a progression of activities that a business or firm performs in order to deliver goods and services of value to an end customer. The concept comes from the field of business management and was first described by Michael Porter in his 1985 best-seller, Competitive Advantage: Creating and Sustaining Superior Performance.

The idea of [Porter's Value Chain] is based on the process view of organizations, the idea of seeing a manufacturing organization as a system, made up of subsystems each with inputs, transformation processes and outputs. Inputs, transformation processes, and outputs involve the acquisition and consumption of resources – money, labour, materials, equipment, buildings, land, administration and management. How value chain activities are carried out determines costs and affects profits.

Service management in the manufacturing context, is integrated into supply chain management as the intersection between the actual sales and the customer point of view. The aim of high-performance service management is to optimize the service-intensive supply chains, which are usually more complex than the typical finished-goods supply chain. Most service-intensive supply chains require larger inventories and tighter integration with field service and third parties. They also must accommodate inconsistent and uncertain demand by establishing more advanced information and product flows. Moreover, all processes must be coordinated across numerous service locations with large numbers of parts and multiple levels in the supply chain.

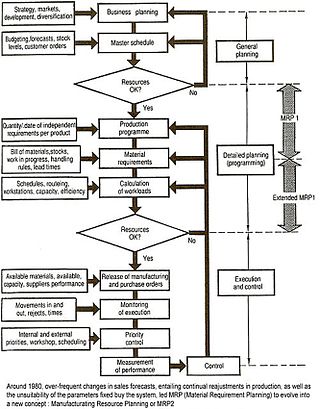

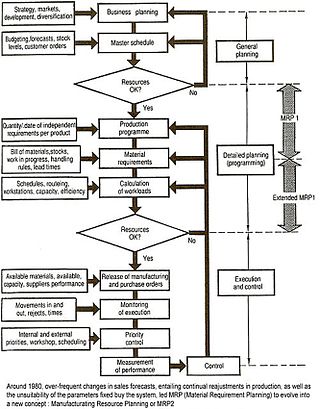

Manufacturingresource planning is a method for the effective planning of all resources of a manufacturing company. Ideally, it addresses operational planning in units, financial planning, and has a simulation capability to answer "what-if" questions and is an extension of closed-loop MRP.

Demand management is a planning methodology used to forecast, plan for and manage the demand for products and services. This can be at macro-levels as in economics and at micro-levels within individual organizations. For example, at macro-levels, a government may influence interest rates to regulate financial demand. At the micro-level, a cellular service provider may provide free night and weekend use to reduce demand during peak hours.

Oracle Applications comprise the applications software or business software of the Oracle Corporation both in the cloud and on-premises. The term refers to the non-database and non-middleware parts. The suite of applications includes enterprise resource planning, enterprise performance management, supply chain & manufacturing, human capital management, and advertising and customer experience.

The term demand chain has been used in a business and management context as contrasting terminology alongside, or in place of, "supply chain". Madhani suggests that the demand chain "comprises all the demand processes necessary to understand, create, and stimulate customer demand". Cranfield School of Management academic Martin Christopher has suggested that "ideally the supply chain should become a demand chain", explaining that ideally all product logistics and processing should occur "in response to a known customer requirement".

Demand-chain management (DCM) is the management of relationships between suppliers and customers to deliver the best value to the customer at the least cost to the demand chain as a whole. Demand-chain management is similar to supply-chain management but with special regard to the customers.

Enterprise modelling is the abstract representation, description and definition of the structure, processes, information and resources of an identifiable business, government body, or other large organization.

Revenue management is a discipline to maximize profit by optimizing rate (ADR) and occupancy (Occ). In its day to day application the maximization of RevPAR is paramount.

The Supply Chain Operations Reference (SCOR) model is a process reference model originally developed and endorsed by the Supply Chain Council, now a part of ASCM, as the cross-industry, standard diagnostic tool for supply chain management. The SCOR model describes the business activities associated with satisfying a customer's demand, which include plan, source, make, deliver, return, and enable. Use of the model includes analyzing the current state of a company's processes and goals, quantifying operational performance, and comparing company performance to benchmark data. SCOR has developed a set of metrics for supply chain performance, and ASCM members have formed industry groups to collect best practices information that companies can use to elevate their supply chain models.

Business analytics (BA) refers to the skills, technologies, and practices for iterative exploration and investigation of past business performance to gain insight and drive business planning. Business analytics focuses on developing new insights and understanding of business performance based on data and statistical methods. In contrast, business intelligence traditionally focuses on using a consistent set of metrics to both measure past performance and guide business planning. In other words, business intelligence focusses on description, while business analytics focusses on prediction and prescription.

Technology management is a set of management disciplines that allows organizations in managing their technological fundamentals to create customer advantage. Typical concepts used in technology management are:

Sales and operations planning (S&OP) is an integrated business management process through which the executive/leadership team continually achieves focus, alignment, and synchronization among all organization functions. The S&OP process includes an updated forecast that leads to a sales plan, production plan, inventory plan, customer lead time (backlog) plan, new product development plan, strategic initiative plan, and resulting financial plan. Plan frequency and planning horizon depend on the specifics of the context. Short product life cycles and high demand volatility require a tighter S&OP than steadily consumed products. Done well, the S&OP process also enables effective supply chain management.

Customer demand planning (CDP) is a business-planning process that enables sales teams to develop demand forecasts as input to service-planning processes, production, inventory planning and revenue planning.

Service chain optimization is the application of processes and tools that embrace all functions for improving the efficiency, productivity and, eventually, the profitability of service organizations. In this regard, profitability of a service organization is measured by the revenue generated from service demand, and by the costs due to activity of the enterprise's human resources. Service chains consider the full life-cycle of service demand from early stages of forecasting, through planning, scheduling, dispatch, execution and post-analysis.

Petrolsoft Corporation (1989–2000) was a supply chain management software company with a focus on the petroleum industry. Petrolsoft Corporation was founded at Stanford University in 1989 by Bill Miller and David Gamboa as Petrolsoft Software Group. It was later incorporated in 1992. Petrolsoft introduced demand-driven inventory management to the petroleum industry.

Trade promotion forecasting (TPF) is the process that attempts to discover multiple correlations between trade promotion characteristics and historic demand in order to provide accurate demand forecasting for future campaigns. The ability to distinguish the uplift or demand due to the impact of the trade promotion as opposed to baseline demand is fundamental to model promotion behavior. Model determination enables what-if analysis to evaluate different campaign scenarios with the goal of improving promotion effectiveness and ROI at the product-channel level by selecting the best scenario.