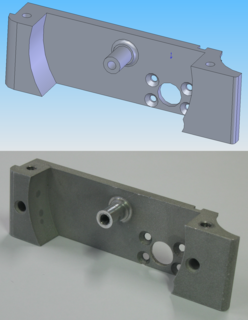

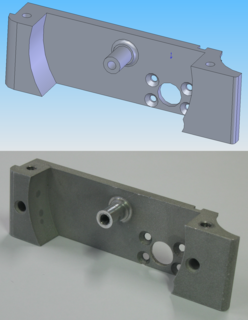

Computer-aided design (CAD) is the use of computers to aid in the creation, modification, analysis, or optimization of a design. This software is used to increase the productivity of the designer, improve the quality of design, improve communications through documentation, and to create a database for manufacturing. Designs made through CAD software are helpful in protecting products and inventions when used in patent applications. CAD output is often in the form of electronic files for print, machining, or other manufacturing operations. The terms computer-aided drafting (CAD) and computer aided design and drafting (CADD) are also used.

Computer-aided manufacturing (CAM) also known as computer-aided modeling or computer-aided machining is the use of software to control machine tools in the manufacturing of work pieces. This is not the only definition for CAM, but it is the most common; CAM may also refer to the use of a computer to assist in all operations of a manufacturing plant, including planning, management, transportation and storage. Its primary purpose is to create a faster production process and components and tooling with more precise dimensions and material consistency, which in some cases, uses only the required amount of raw material, while simultaneously reducing energy consumption. CAM is now a system used in schools and lower educational purposes. CAM is a subsequent computer-aided process after computer-aided design (CAD) and sometimes computer-aided engineering (CAE), as the model generated in CAD and verified in CAE can be input into CAM software, which then controls the machine tool. CAM is used in many schools alongside computer-aided design (CAD) to create objects.

Autodesk, Inc. is an American multinational software corporation that makes software products and services for the architecture, engineering, construction, manufacturing, media, education, and entertainment industries. Autodesk is headquartered in San Francisco, California, and has offices worldwide. Its U.S. offices are located in the states of California, Oregon, Colorado, Texas, Michigan, New Hampshire and Massachusetts. Its Canada offices are located in the provinces of Ontario, Quebec, and Alberta.

Mastercam is a suite of Computer-Aided Manufacturing (CAM) and CAD/CAM software applications. Founded in MA in 1983, CNC Software, LLC is one of the oldest developers of PC-based computer-aided design / computer-aided manufacturing (CAD/CAM) software. They are one of the first to introduce CAD/CAM software designed for both machinists and engineers. Mastercam, CNC Software's main product, started as a 2D CAM system with CAD tools that let machinists design virtual parts on a computer screen and also guided computer numerical controlled (CNC) machine tools in the manufacture of parts. Since then, Mastercam has grown into the most widely used CAD/CAM package in the world. CNC Software, LLC is now located in Tolland, Connecticut.

Autodesk Alias is a family of computer-aided industrial design (CAID) software predominantly used in automotive design and industrial design for generating class A surfaces using Bézier surface and non-uniform rational B-spline (NURBS) modeling method.

G-code is the most widely used computer numerical control (CNC) programming language. It is used mainly in computer-aided manufacturing to control automated machine tools, and has many variants.

A CNC wood router is a CNC router tool that creates objects from wood. CNC stands for computer numerical control. The CNC works on the Cartesian coordinate system for 3D motion control. Parts of a project can be designed in the computer with a CAD/CAM program, and then cut automatically using a router or other cutters to produce a finished part. The CNC router is ideal for hobbies, engineering prototyping, product development, art, and production work.

Tebis is a CAD/CAM software provided by Tebis AG, with headquarters in Martinsried near Munich/Germany. Development locations: Martinsried and Norderstedt, Germany International locations: China, Spain, France, Italy, Portugal, Sweden, United Kingdom, USA

Parasolid is a geometric modeling kernel originally developed by Shape Data Limited, now owned and developed by Siemens Digital Industries Software. It can be licensed by other companies for use in their 3D computer graphics software products.

CAD data exchange is a method of drawing data exchange used to translate between different Computer-aided design (CAD) authoring systems or between CAD and other downstream CAx systems.

Delcam is a supplier of advanced CAD/CAM software for the manufacturing industry. The company has grown steadily since being founded formally in 1977, after initial development work at Cambridge University, UK. It is now a global developer of product design and manufacturing software, with subsidiaries and joint ventures in North America, South America, Europe and Asia with a total staff of over 800 people and local support provided from over 300 re-seller offices worldwide. It was listed on the London Stock Exchange until 6 February 2014, when it was acquired by Autodesk. It now operates as a wholly owned, independently operated subsidiary of Autodesk.

Vero Software is a company based in Cheltenham, England, that specialises in CAD CAM.

Digital modeling and fabrication is a design and production process that combines 3D modeling or computing-aided design (CAD) with additive and subtractive manufacturing. Additive manufacturing is also known as 3D printing, while subtractive manufacturing may also be referred to as machining, and many other technologies can be exploited to physically produce the designed objects.

A computer numerical control (CNC) router is a computer-controlled cutting machine which typically mounts a hand-held router as a spindle which is used for cutting various materials, such as wood, composites, metals, plastics, glass, and foams. CNC routers can perform the tasks of many carpentry shop machines such as the panel saw, the spindle moulder, and the boring machine. They can also cut joinery such as mortises and tenons.

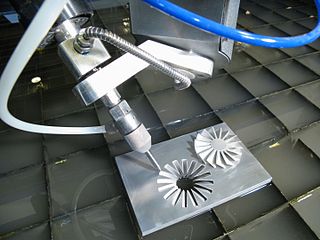

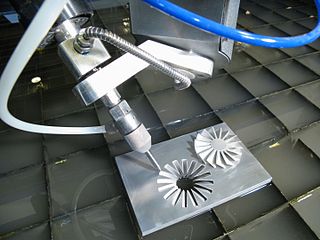

Multiaxis machining is a manufacturing process that involves tools that move in 4 or more directions and are used to manufacture parts out of metal or other materials by milling away excess material, by water jet cutting or by laser cutting. This type of machining was originally performed mechanically on large complex machines. These machines operated on 4, 5, 6, and even 12 axes which were controlled individually via levers that rested on cam plates. The cam plates offered the ability to control the tooling device, the table in which the part is secured, as well as rotating the tooling or part within the machine. Due to the machines size and complexity it took extensive amounts of time to set them up for production. Once computer numerically controlled machining was introduced it provided a faster, more efficient method for machining complex parts.

WorkNC is a Computer aided manufacturing (CAM) software developed by Sescoi for multi-axis machining.

SprutCAM is a high-level CAM program that runs on Microsoft Windows and was developed by SprutCAM Tech Ltd. SprutCAM provide off-line CNC programming for cutting, wire EDM, 2, 3 and multi axial machining with support Multi-tasking Turn-Milling centers with live tooling and robots (OLP).

Digital manufacturing is an integrated approach to manufacturing that is centered around a computer system. The transition to digital manufacturing has become more popular with the rise in the quantity and quality of computer systems in manufacturing plants. As more automated tools have become used in manufacturing plants it has become necessary to model, simulate, and analyze all of the machines, tooling, and input materials in order to optimize the manufacturing process. Overall, digital manufacturing can be seen sharing the same goals as computer-integrated manufacturing (CIM), flexible manufacturing, lean manufacturing, and design for manufacturability (DFM). The main difference is that digital manufacturing was evolved for use in the computerized world.

Designers have used computers for calculations since their invention. Digital computers were used in power system analysis or optimization as early as proto-"Whirlwind" in 1949. Circuit design theory or power network methodology was algebraic, symbolic, and often vector-based.