Carbon dioxide is a chemical compound with the chemical formula CO2. It is made up of molecules that each have one carbon atom covalently double bonded to two oxygen atoms. It is found in the gas state at room temperature, and as the source of available carbon in the carbon cycle, atmospheric CO2 is the primary carbon source for life on Earth. In the air, carbon dioxide is transparent to visible light but absorbs infrared radiation, acting as a greenhouse gas. Carbon dioxide is soluble in water and is found in groundwater, lakes, ice caps, and seawater. When carbon dioxide dissolves in water, it forms carbonate and mainly bicarbonate, which causes ocean acidification as atmospheric CO2 levels increase.

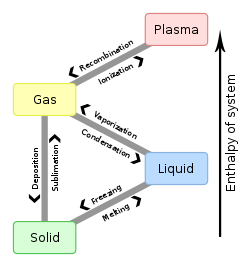

In the physical sciences, a phase is a region of material that is chemically uniform, physically distinct, and (often) mechanically separable. In a system consisting of ice and water in a glass jar, the ice cubes are one phase, the water is a second phase, and the humid air is a third phase over the ice and water. The glass of the jar is another separate phase.

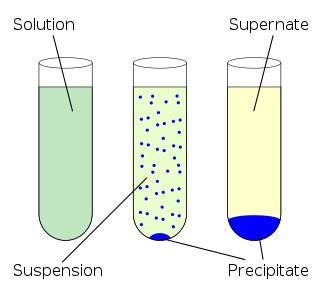

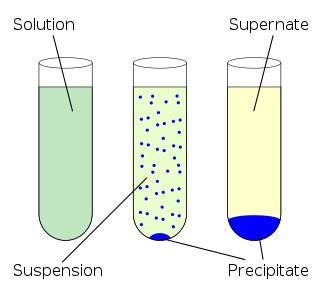

In chemistry, a solution is a special type of homogeneous mixture composed of two or more substances. In such a mixture, a solute is a substance dissolved in another substance, known as a solvent. If the attractive forces between the solvent and solute particles are greater than the attractive forces holding the solute particles together, the solvent particles pull the solute particles apart and surround them. These surrounded solute particles then move away from the solid solute and out into the solution. The mixing process of a solution happens at a scale where the effects of chemical polarity are involved, resulting in interactions that are specific to solvation. The solution usually has the state of the solvent when the solvent is the larger fraction of the mixture, as is commonly the case. One important parameter of a solution is the concentration, which is a measure of the amount of solute in a given amount of solution or solvent. The term "aqueous solution" is used when one of the solvents is water.

In chemistry, solubility is the ability of a substance, the solute, to form a solution with another substance, the solvent. Insolubility is the opposite property, the inability of the solute to form such a solution.

Dry cleaning is any cleaning process for clothing and textiles using a solvent other than water.

Micronization is the process of reducing the average diameter of a solid material's particles. Traditional techniques for micronization focus on mechanical means, such as milling and grinding. Modern techniques make use of the properties of supercritical fluids and manipulate the principles of solubility.

A coolant is a substance, typically liquid, that is used to reduce or regulate the temperature of a system. An ideal coolant has high thermal capacity, low viscosity, is low-cost, non-toxic, chemically inert and neither causes nor promotes corrosion of the cooling system. Some applications also require the coolant to be an electrical insulator.

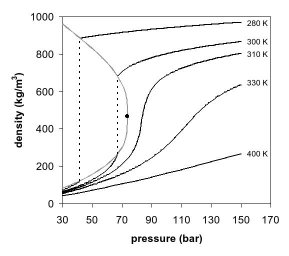

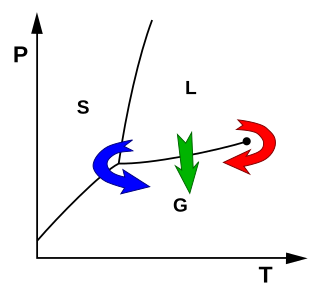

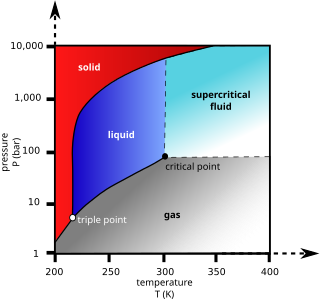

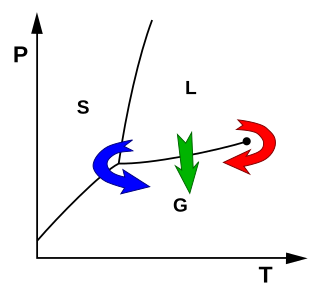

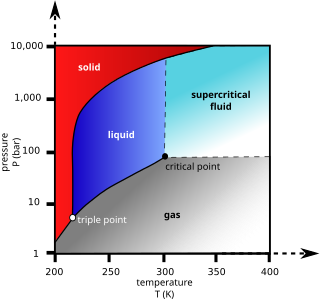

In thermodynamics, a critical point is the end point of a phase equilibrium curve. One example is the liquid–vapor critical point, the end point of the pressure–temperature curve that designates conditions under which a liquid and its vapor can coexist. At higher temperatures, the gas cannot be liquefied by pressure alone. At the critical point, defined by a critical temperatureTc and a critical pressurepc, phase boundaries vanish. Other examples include the liquid–liquid critical points in mixtures, and the ferromagnet–paramagnet transition in the absence of an external magnetic field.

Supercritical drying, also known as critical point drying, is a process to remove liquid in a precise and controlled way. It is useful in the production of microelectromechanical systems (MEMS), the drying of spices, the production of aerogel, the decaffeination of coffee and in the preparation of biological specimens.

Supercritical fluid extraction (SFE) is the process of separating one component (the extractant) from another (the matrix) using supercritical fluids as the extracting solvent. Extraction is usually from a solid matrix, but can also be from liquids. SFE can be used as a sample preparation step for analytical purposes, or on a larger scale to either strip unwanted material from a product (e.g. decaffeination) or collect a desired product (e.g. essential oils). These essential oils can include limonene and other straight solvents. Carbon dioxide (CO2) is the most used supercritical fluid, sometimes modified by co-solvents such as ethanol or methanol. Extraction conditions for supercritical carbon dioxide are above the critical temperature of 31 °C and critical pressure of 74 bar. Addition of modifiers may slightly alter this. The discussion below will mainly refer to extraction with CO2, except where specified.

Supercritical carbon dioxide is a fluid state of carbon dioxide where it is held at or above its critical temperature and critical pressure.

Sulfolane (also tetramethylene sulfone, systematic name: 1λ6-thiolane-1,1-dione) is an organosulfur compound, formally a cyclic sulfone, with the formula (CH2)4SO2. It is a colorless liquid commonly used in the chemical industry as a solvent for extractive distillation and chemical reactions. Sulfolane was originally developed by the Shell Oil Company in the 1960s as a solvent to purify butadiene. Sulfolane is a polar aprotic solvent, and it is readily soluble in water.

Supercritical fluid chromatography (SFC) is a form of normal phase chromatography that uses a supercritical fluid such as carbon dioxide as the mobile phase. It is used for the analysis and purification of low to moderate molecular weight, thermally labile molecules and can also be used for the separation of chiral compounds. Principles are similar to those of high performance liquid chromatography (HPLC); however, SFC typically utilizes carbon dioxide as the mobile phase. Therefore, the entire chromatographic flow path must be pressurized. Because the supercritical phase represents a state whereby bulk liquid and gas properties converge, supercritical fluid chromatography is sometimes called convergence chromatography. The idea of liquid and gas properties convergence was first envisioned by Giddings.

A transcritical cycle is a closed thermodynamic cycle where the working fluid goes through both subcritical and supercritical states. In particular, for power cycles the working fluid is kept in the liquid region during the compression phase and in vapour and/or supercritical conditions during the expansion phase. The ultrasupercritical steam Rankine cycle represents a widespread transcritical cycle in the electricity generation field from fossil fuels, where water is used as working fluid. Other typical applications of transcritical cycles to the purpose of power generation are represented by organic Rankine cycles, which are especially suitable to exploit low temperature heat sources, such as geothermal energy, heat recovery applications or waste to energy plants. With respect to subcritical cycles, the transcritical cycle exploits by definition higher pressure ratios, a feature that ultimately yields higher efficiencies for the majority of the working fluids. Considering then also supercritical cycles as a valid alternative to the transcritical ones, the latter cycles are capable of achieving higher specific works due to the limited relative importance of the work of compression work. This evidences the extreme potential of transcritical cycles to the purpose of producing the most power with the least expenditure.

Superheated water is liquid water under pressure at temperatures between the usual boiling point, 100 °C (212 °F) and the critical temperature, 374 °C (705 °F). It is also known as "subcritical water" or "pressurized hot water". Superheated water is stable because of overpressure that raises the boiling point, or by heating it in a sealed vessel with a headspace, where the liquid water is in equilibrium with vapour at the saturated vapor pressure. This is distinct from the use of the term superheating to refer to water at atmospheric pressure above its normal boiling point, which has not boiled due to a lack of nucleation sites.

Hydrothermal liquefaction (HTL) is a thermal depolymerization process used to convert wet biomass, and other macromolecules, into crude-like oil under moderate temperature and high pressure. The crude-like oil has high energy density with a lower heating value of 33.8-36.9 MJ/kg and 5-20 wt% oxygen and renewable chemicals. The process has also been called hydrous pyrolysis.

In fluid dynamics, the Frenkel line is a proposed boundary on the phase diagram of a supercritical fluid, separating regions of qualitatively different behavior. Fluids on opposite sides of the line have been described as "liquidlike" or "gaslike", and exhibit different behaviors in terms of oscillation, excitation modes, and diffusion.

Carbon dioxide cleaning (CO2 cleaning) comprises a family of methods for parts cleaning and sterilization, using carbon dioxide in its various phases. Due to being non-destructive, non-abrasive, and residue-free, it is often preferred for use on delicate surfaces. CO2 cleaning has found application in the aerospace, automotive, electronics, medical, and other industries. Carbon dioxide snow cleaning has been used to remove particles and organic residues from metals, polymers, ceramics, glasses, and other materials, and from surfaces including hard drives and optical surfaces.

The use of ionic liquids in carbon capture is a potential application of ionic liquids as absorbents for use in carbon capture and sequestration. Ionic liquids, which are salts that exist as liquids near room temperature, are polar, nonvolatile materials that have been considered for many applications. The urgency of climate change has spurred research into their use in energy-related applications such as carbon capture and storage.

Liquid carbon dioxide is the liquid state of carbon dioxide, which cannot occur under atmospheric pressure. It can only exist at a pressure above 5.1 atm, under 31.1 °C (88.0 °F) and above −56.6 °C (−69.9 °F). Low-temperature carbon dioxide is commercially used in its solid form, commonly known as "dry ice". Solid CO

2 sublimes at 194.65 K at Earth atmospheric pressure — that is, it transitions directly from solid to gas without an intermediate liquid stage. The uses and applications of liquid carbon dioxide include decaffeinating coffee, extracting virgin olive oil from olive paste, in fire extinguishers, and as a coolant.